Welding Blanket Specs: Key Features, Materials, and Safety Standards

Summary:This guide explains welding blanket specifications including material types, temperature ratings, sizes, and safety standards to help you choose the right protection for your welding projects.

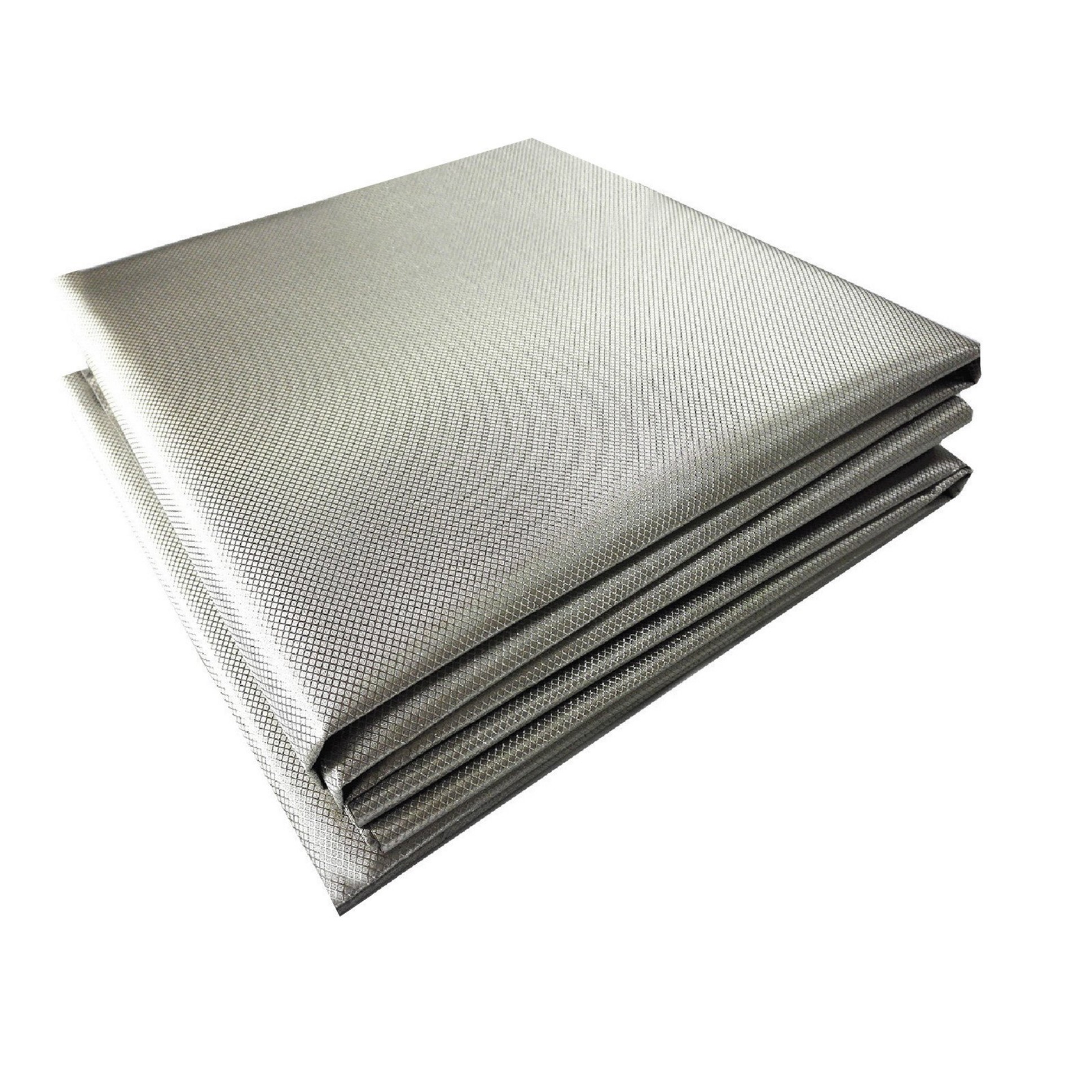

Understanding Welding Blanket Specifications

When selecting a welding blanket, you need to check several key specifications to ensure proper protection. The most important welding blanket specs include material composition, temperature resistance, dimensions, thickness, and compliance with safety standards. These factors determine how well the blanket will protect your work area from sparks, slag, and heat.

Material Types and Their Properties

Welding blankets come in three primary materials, each with different specs:

- Fiberglass:The most common type, rated for 1000°F (538°C). Fiberglass welding blanket specs typically show 18oz/sq.yd weight and excellent flexibility.

- Silica:Handles up to 1800°F (982°C). Silica welding blanket specs often indicate superior heat reflection and durability.

- Carbon Fiber:For extreme heat up to 3000°F (1649°C). These welding blanket specs include high tensile strength and chemical resistance.

Temperature Ratings Explained

The temperature rating is the most critical spec in welding blankets. You'll find two numbers:

- Continuous exposure rating:The maximum temperature the blanket can handle for prolonged periods (typically 1000-1800°F)

- Peak temperature rating:The highest short-term temperature the material can withstand (often 500-1000°F higher than continuous rating)

Always choose a blanket whose specs exceed your typical welding temperatures by at least 200°F for safety margins.

Size and Thickness Considerations

Welding blanket specs include dimensions and thickness that affect coverage and protection:

| Size (ft) | Thickness (mm) | Best For |

|---|---|---|

| 3×3 | 1.5-2 | Small welding jobs, portable use |

| 6×6 | 2-3 | Medium projects, general workshop use |

| 8×8 or larger | 3-5 | Industrial applications, heavy-duty welding |

Thicker blankets in the specs mean better protection but reduced flexibility. Choose based on your mobility needs versus protection requirements.

Safety Standards and Certifications

Quality welding blanket specs should include compliance with these standards:

- OSHA 1910.252:Covers welding, cutting, and brazing safety requirements

- NFPA 51B:Standard for fire prevention during welding operations

- ASTM F955:Standard test method for evaluating heat transfer through materials

Look for these certifications in the product specs to ensure your blanket meets industry safety benchmarks.

Durability and Maintenance Specs

Check these welding blanket specs for long-term performance:

- Tensile strength:Measured in pounds (typically 200-500 lbs for quality blankets)

- Puncture resistance:Important for industrial environments

- Washability:Some blankets can be washed, others require brushing only

Higher durability specs mean longer service life but often at higher cost. Balance your budget with expected usage frequency.

Special Features to Consider

Modern welding blanket specs may include additional features:

- Grommets:For hanging or securing the blanket (check spacing specs)

- Reinforced edges:Prevents fraying (look for double-stitching specs)

- Chemical resistance:Important for certain industrial applications

- UV stability:For outdoor use specifications

How to Read Welding Blanket Spec Sheets

When reviewing product specs, pay attention to:

- Material composition percentage (e.g., 100% fiberglass vs. blends)

- Actual tested temperature ratings (not just manufacturer claims)

- Weight per square yard (heavier usually means more protection)

- Certification listings (should be from recognized testing labs)

Reputable manufacturers provide detailed spec sheets with test data to support their claims.

Matching Welding Blanket Specs to Your Needs

Consider these factors when selecting based on specs:

- Welding type:MIG/TIG welding typically needs lower temp specs than plasma cutting

- Work environment:Confined spaces may require smaller size specs

- Frequency of use:Occasional users can often choose lower-spec blankets

- Budget:Higher specs command premium prices but offer better protection

Conclusion

Understanding welding blanket specs ensures you get the right protection for your specific needs. Always verify temperature ratings, material composition, size, and safety certifications before purchasing. Remember that higher-spec blankets provide better protection and typically last longer, making them more cost-effective for frequent users.