Welding Blankets FM450 ANSI FM 4950: Safety & Performance Guide

Summary:Welding blankets FM450 ANSI FM 4950 certified provide superior protection against sparks, slag, and heat. This guide explains their features, safety standards, proper use, and how they compare to other welding protection solutions.

What Are Welding Blankets FM450 ANSI FM 4950?

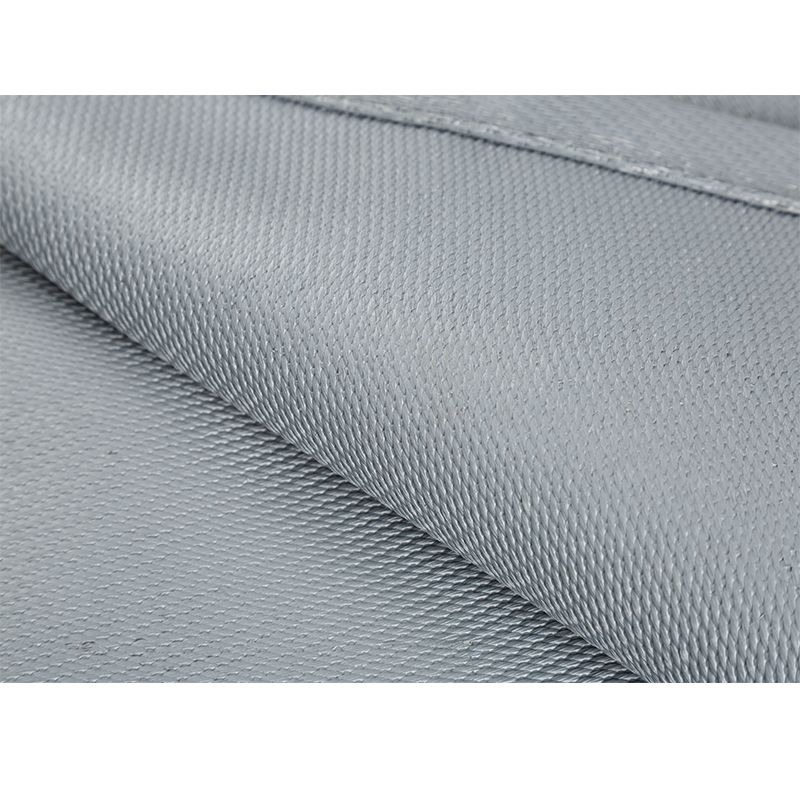

When you work with welding equipment, safety should be your top priority. Welding blankets FM450 ANSI FM 4950 certified are specially designed protective covers that meet rigorous safety standards. These blankets protect workers and surrounding areas from sparks, molten metal, and intense heat generated during welding operations.

The "FM450" designation means these blankets have been tested to withstand temperatures up to 450°F continuously. The "ANSI FM 4950" certification indicates compliance with American National Standards Institute and Factory Mutual standards for welding protection.

Key Features of FM450 ANSI FM 4950 Welding Blankets

These welding blankets offer several important features:

- Heat resistance:Withstands temperatures up to 450°F continuously and higher temperatures for short exposures

- Spark and slag protection:Prevents ignition from welding sparks and hot metal fragments

- Flexible material:Easy to drape over equipment or work areas without cracking

- Durable construction:Resists tears and abrasions common in welding environments

- Lightweight:Easy to handle and position while providing excellent protection

Why ANSI FM 4950 Certification Matters

The ANSI FM 4950 standard ensures your welding blanket meets strict safety requirements. When you choose FM450 ANSI FM 4950 certified blankets, you get:

- Verified performance through standardized testing

- Consistent quality across manufacturers

- Reliable protection you can trust in hazardous environments

- Compliance with workplace safety regulations

Proper Use of Welding Blankets FM450 ANSI FM 4950

To get maximum protection from your welding blanket:

- Inspect the blanket before each use for tears or damage

- Cover all exposed surfaces within the welding area

- Overlap multiple blankets by at least 6 inches when covering large areas

- Keep the blanket clean from oil and grease buildup

- Store properly when not in use to prevent unnecessary wear

Comparing FM450 to Other Welding Protection Options

While other welding protection solutions exist, FM450 ANSI FM 4950 blankets offer unique advantages:

| Protection Type | Temperature Resistance | Flexibility | Cost |

|---|---|---|---|

| FM450 Blankets | 450°F continuous | High | Moderate |

| Fiberglass Curtains | Higher | Low | Higher |

| Leather Shields | Lower | Medium | Higher |

Maintenance and Care Tips

Proper maintenance extends the life of your FM450 ANSI FM 4950 welding blanket:

- Clean with mild soap and water - avoid harsh chemicals

- Inspect stitching and edges regularly

- Replace if you notice significant wear or damage

- Store in a dry location away from direct sunlight

- Fold rather than roll to prevent crease damage

Choosing the Right Size and Thickness

Welding blankets FM450 ANSI FM 4950 come in various sizes and thicknesses. Consider these factors when selecting:

- Work area size:Choose a blanket that covers all exposed areas with extra margin

- Welding type:Higher heat processes may require thicker blankets

- Mobility needs:Larger blankets offer more coverage but may be harder to position

- Durability requirements:Thicker blankets last longer in heavy-use environments

Common Applications

FM450 ANSI FM 4950 welding blankets are versatile protection solutions for:

- Shielding flammable materials near welding areas

- Protecting sensitive equipment from sparks and heat

- Creating temporary welding curtains in open areas

- Covering workbenches and floors during welding operations

- Protecting vehicles and machinery during repair welding

Safety Considerations

While FM450 ANSI FM 4950 welding blankets provide excellent protection, remember:

- They don't replace proper PPE like gloves and face shields

- Never use damaged blankets - replace them immediately

- Keep fire extinguishers accessible when welding

- Monitor for heat buildup under the blanket during extended use

- Follow all other standard welding safety procedures