Asbestos Welding Blanket Safety Guide: Protection & Alternatives

This guide explains asbestos welding blankets' uses, risks, and modern alternatives. You'll learn proper handling techniques, safety precautions, and how to choose effective heat-resistant protection for welding projects.

What Is an Asbestos Welding Blanket?

An asbestos welding blanket is a heat-resistant protective sheet traditionally used in metalworking. Made from woven asbestos fibers, these blankets withstand temperatures up to 1,000°F (538°C). You might find them in older workshops or industrial settings, though modern alternatives are now recommended.

Key Uses of Asbestos Welding Blankets

These blankets serve multiple purposes in welding environments:

- Protecting floors and work surfaces from sparks and molten metal

- Creating fire barriers around welding areas

- Covering flammable materials near work zones

- Shielding sensitive equipment from heat damage

Health Risks You Should Know

While effective, asbestos welding blankets pose serious health hazards. When disturbed, asbestos fibers become airborne. If you inhale them, they can cause:

- Asbestosis (lung scarring)

- Lung cancer

- Mesothelioma (rare cancer affecting lung lining)

Symptoms often appear 20-50 years after exposure. There's no safe exposure level - even brief contact risks future health problems.

Safe Handling Procedures

If you must handle an asbestos welding blanket:

- Wear a NIOSH-approved respirator (P100 filter)

- Use disposable coveralls and gloves

- Work in well-ventilated areas

- Never cut or tear the blanket

- Wet the blanket before moving to reduce dust

- Dispose of properly as hazardous waste

Modern Alternatives to Asbestos Welding Blankets

Safer, equally effective options exist:

| Material | Max Temperature | Advantages |

|---|---|---|

| Fiberglass | 1,200°F (649°C) | Non-toxic, flexible, affordable |

| Silica | 2,300°F (1,260°C) | Excellent heat resistance, lightweight |

| Ceramic Fiber | 2,300°F (1,260°C) | Superior insulation, chemical resistant |

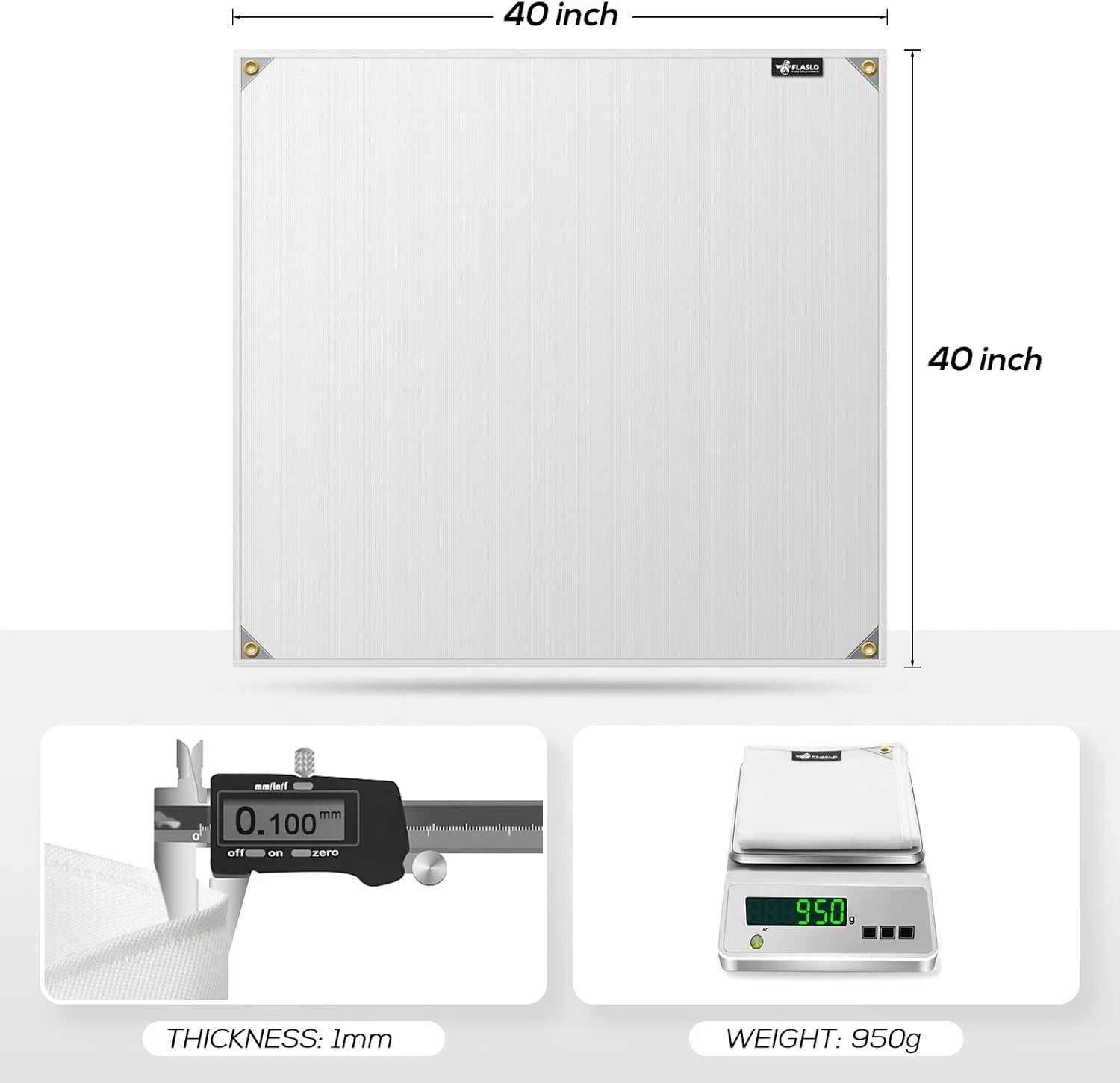

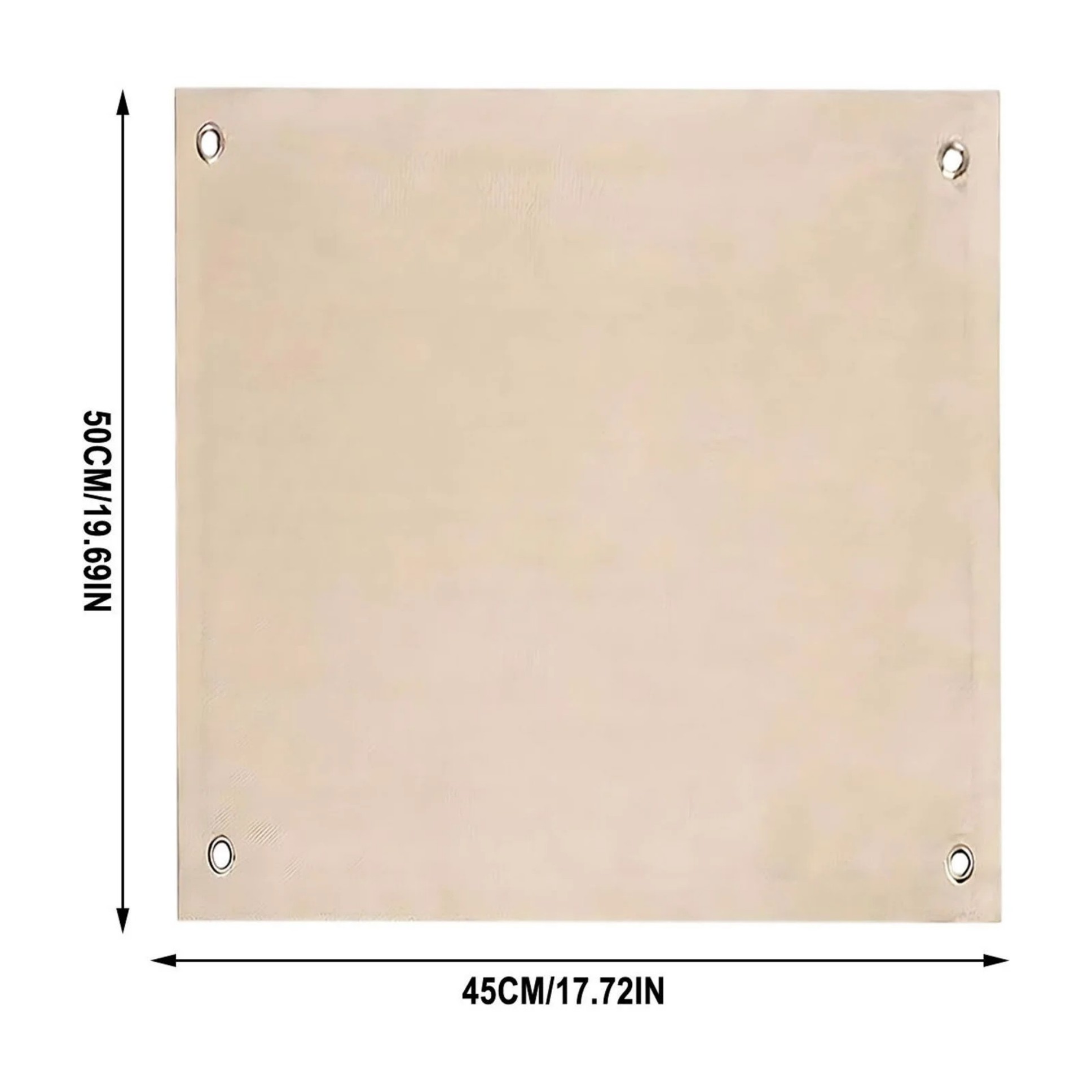

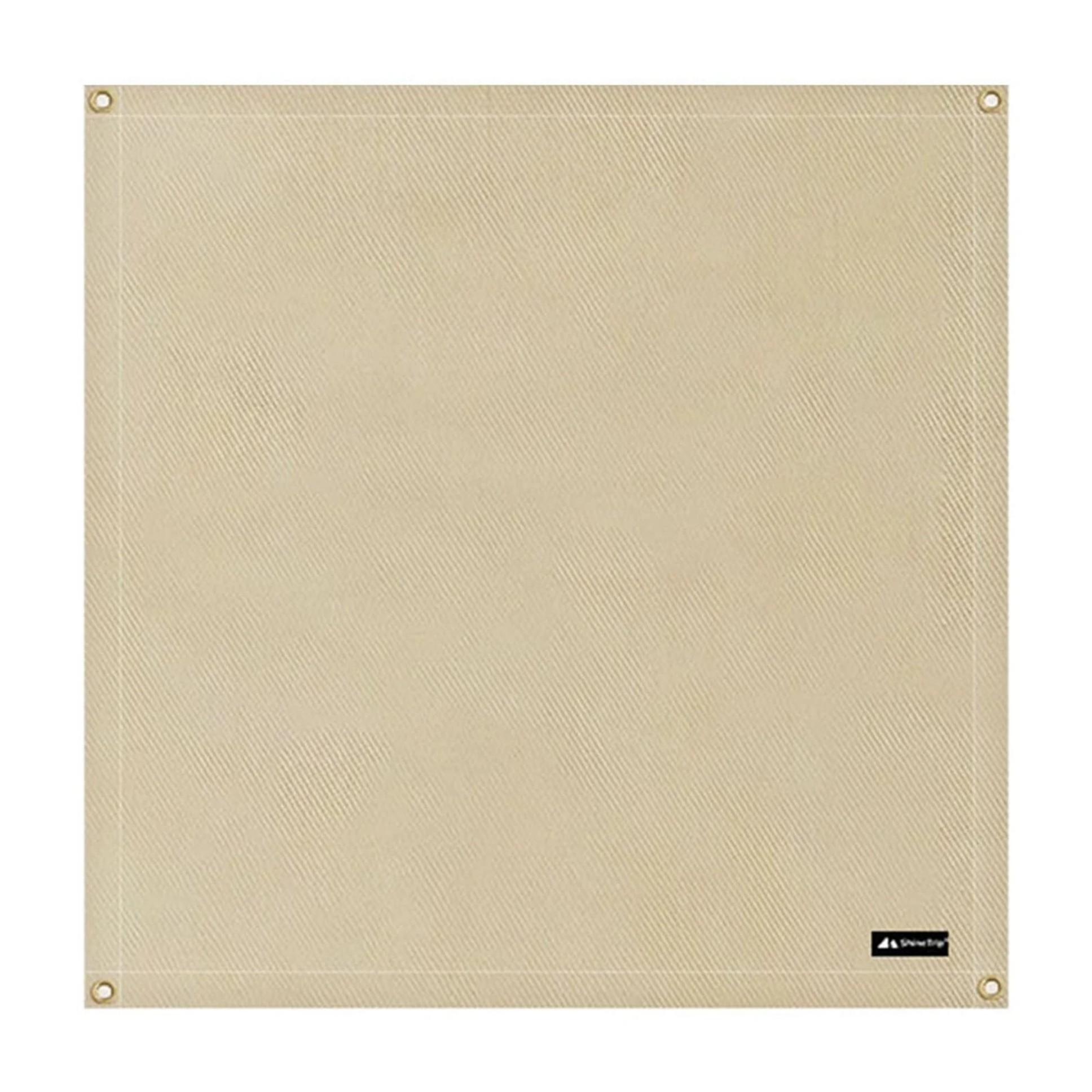

Choosing the Right Welding Blanket

Consider these factors when selecting a replacement:

- Temperature rating: Must exceed your maximum working temperature

- Size: Should cover all potential spark zones

- Durability: Look for reinforced edges in high-wear areas

- Certifications: Check for OSHA/NIOSH compliance

Proper Disposal of Old Asbestos Blankets

Never throw asbestos welding blankets in regular trash. Follow these steps:

- Contact local environmental agencies for disposal guidelines

- Hire licensed asbestos abatement professionals

- Seal the blanket in approved asbestos waste bags

- Label clearly as asbestos-containing material

- Transport to designated hazardous waste facilities

Maintenance Tips for Non-Asbestos Blankets

Extend your welding blanket's life with proper care:

- Inspect regularly for tears or thinning areas

- Clean with compressed air (never shake or beat)

- Store flat or rolled - avoid sharp folds

- Replace when more than 10% surface shows wear

Final Safety Recommendations

For maximum protection:

- Replace all asbestos welding blankets immediately

- Train all workers on heat-resistant material safety

- Keep fire extinguishers accessible in welding areas

- Conduct regular equipment inspections

Modern materials offer equal protection without health risks. Investing in safer alternatives protects both your health and legal compliance.