Ceramic Welding Blanket: The Ultimate Heat Protection Solution for Industrial Safety

Ceramic welding blankets provide superior heat protection for welding applications. These specialized safety tools resist extreme temperatures, prevent sparks and slag damage, and offer durable protection for workers and equipment. This guide explains their benefits, uses, and selection criteria.

What Is a Ceramic Welding Blanket?

A ceramic welding blanket is a high-temperature resistant safety barrier made from ceramic fiber materials. Unlike standard welding blankets, these specialized covers can withstand continuous temperatures up to 2300°F (1260°C) and intermittent exposure to even higher heat levels.

You'll find ceramic welding blankets in various industrial settings where extreme heat protection is required. Their unique composition combines ceramic fibers with reinforcing materials to create a flexible yet durable protective layer.

Key Benefits of Ceramic Welding Blankets

- Exceptional heat resistance:Withstands temperatures that would melt ordinary welding blankets

- Spark and slag protection:Prevents hot particles from damaging nearby surfaces

- Thermal insulation:Reduces radiant heat transfer to protect workers and equipment

- Chemical resistance:Handles exposure to most industrial chemicals without degradation

- Lightweight and flexible:Easier to handle than metal alternatives while providing similar protection

Pro Tip: When selecting a ceramic welding blanket, always check the manufacturer's temperature ratings. Some products may look similar but have significantly different performance characteristics.

Common Applications for Ceramic Welding Blankets

You'll find ceramic welding blankets used in numerous industrial scenarios:

- Pipeline welding:Protecting sensitive areas from heat damage during pipe welding operations

- Shipbuilding:Containing sparks and heat in confined shipyard environments

- Power plant maintenance:Shielding critical components during hot work procedures

- Foundry operations:Protecting floors and equipment from molten metal splashes

- Aerospace manufacturing:Safeguarding delicate aircraft components during welding repairs

How to Choose the Right Ceramic Welding Blanket

Selecting the appropriate ceramic welding blanket requires considering several factors:

Temperature requirements:Match the blanket's rating to your specific application needs. Consider both continuous and peak exposure temperatures.

Size and coverage:Measure the area you need to protect and choose a blanket that provides adequate coverage with some overlap.

Thickness:Thicker blankets generally offer better insulation but may be less flexible. Balance protection needs with practical handling requirements.

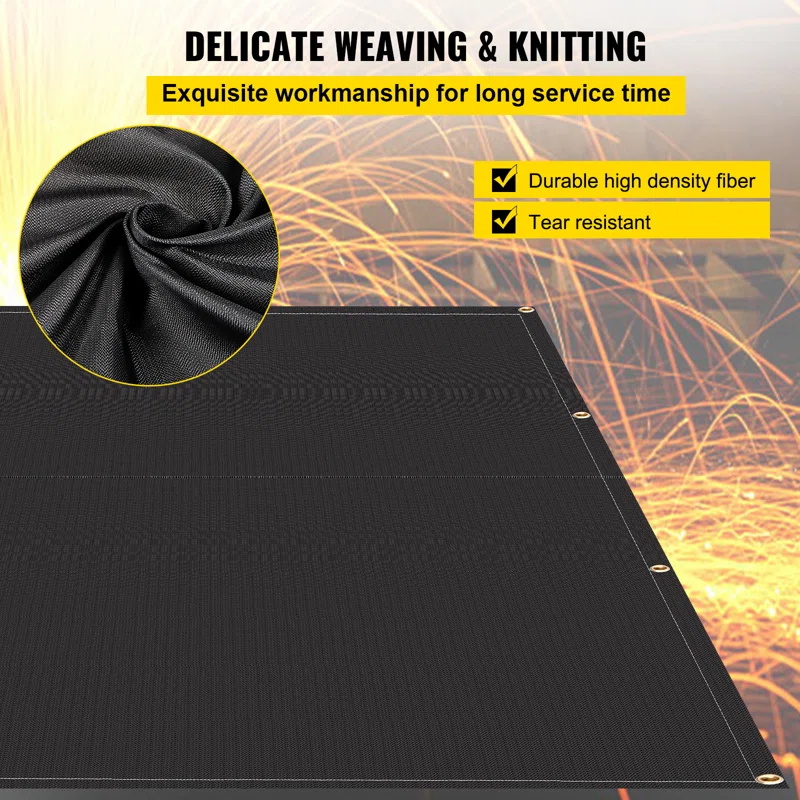

Attachment options:Some blankets come with grommets, ties, or other fastening systems for secure placement.

Chemical exposure:If your application involves chemical splashes, verify the blanket's chemical resistance properties.

Proper Use and Maintenance

To get the most from your ceramic welding blanket:

- Inspect before each use for tears, thinning areas, or other damage

- Store properly when not in use - keep dry and protected from crushing

- Clean gently with compressed air or a soft brush - avoid harsh chemicals

- Replace when the material shows significant wear or reduced insulating properties

- Follow all manufacturer recommendations for care and maintenance

Ceramic vs. Other Welding Blanket Materials

How does ceramic compare to other welding blanket options?

Fiberglass blankets:More affordable but limited to lower temperatures (typically 1000°F/540°C max)

Silica blankets:Good for moderate temperatures but less durable than ceramic options

Metal blankets:Excellent protection but heavier, less flexible, and more expensive

Ceramic blankets:Offer the best combination of high-temperature resistance, flexibility, and durability for most demanding applications

Safety Considerations

While ceramic welding blankets provide excellent protection, remember:

- They don't eliminate all hazards - proper PPE is still required

- Never use damaged blankets - compromised areas reduce protection

- Allow proper cooling time before handling after exposure to extreme heat

- Train all workers on proper use and limitations

Remember: A ceramic welding blanket is just one part of a comprehensive welding safety program. Always follow all applicable safety regulations and best practices.

Conclusion

Ceramic welding blankets provide unmatched protection for high-temperature welding applications. Their superior heat resistance, durability, and flexibility make them essential safety tools in many industrial settings. By understanding their features, proper selection criteria, and maintenance requirements, you can ensure maximum protection for your workers and equipment.

When investing in a ceramic welding blanket, prioritize quality and proper specifications over initial cost savings. The right blanket will deliver long-term value through reliable performance and extended service life.