Welding Blanket Fiberglass: Ultimate Protection for High-Temperature Work

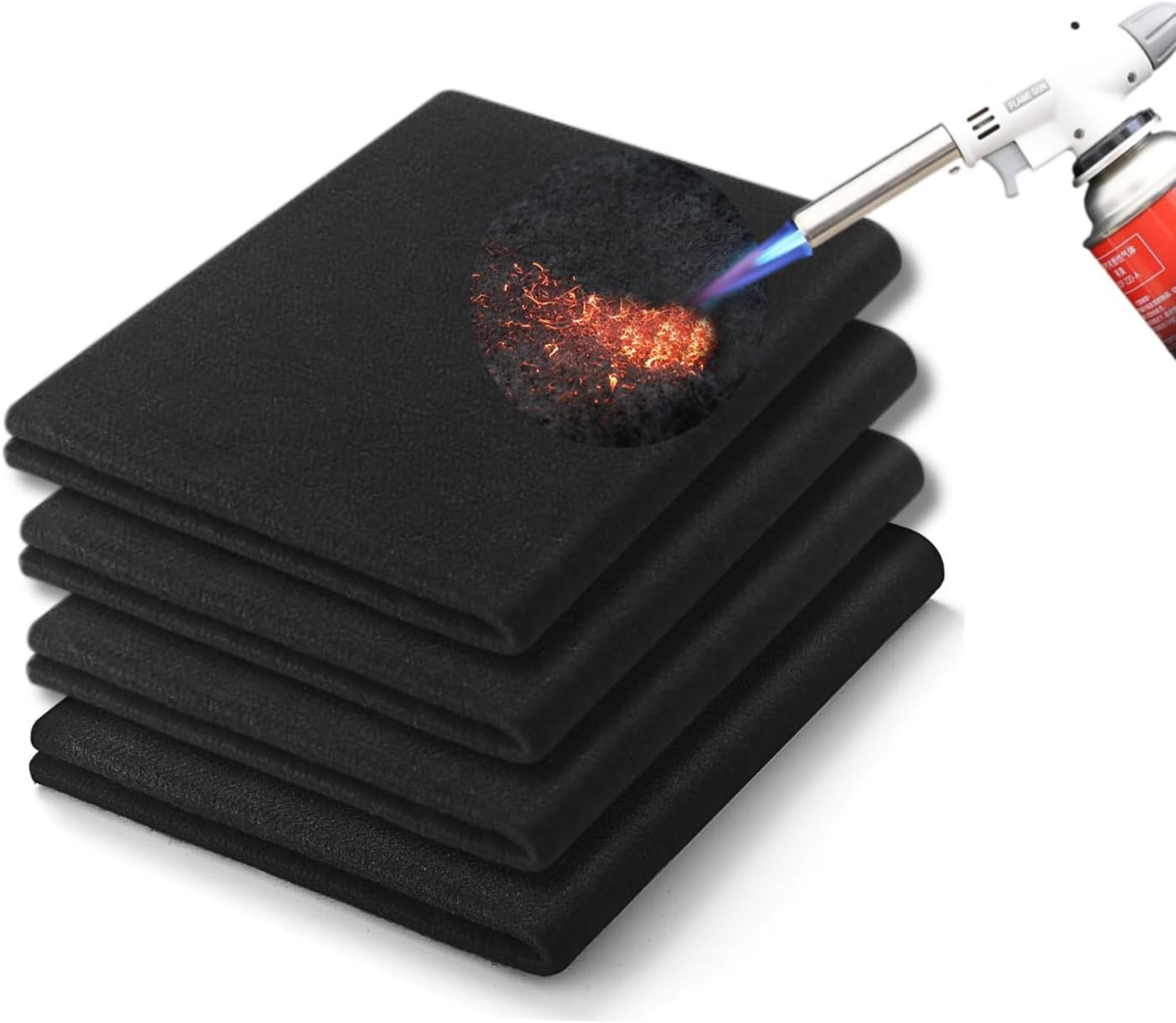

Summary:Fiberglass welding blankets provide essential heat and spark protection for welding, grinding, and other high-temperature applications. These durable, flame-resistant covers shield surfaces from damage while ensuring workplace safety.

What is a Fiberglass Welding Blanket?

When you're working with welding equipment, sparks and molten metal can damage surrounding areas. A welding blanket fiberglass solution creates a protective barrier. These blankets are woven from high-quality fiberglass yarns, offering exceptional heat resistance up to 1000°F (538°C) or more depending on thickness.

Key Benefits of Using Fiberglass Welding Blankets

You'll appreciate these advantages when using fiberglass welding protection:

- Flame resistance:Won't ignite or support combustion

- Heat insulation:Protects surfaces from radiant heat

- Spark containment:Prevents fire hazards from flying debris

- Durability:Resists tears and abrasions better than standard fabrics

- Reusability:Can be used repeatedly with proper care

How to Choose the Right Welding Blanket Fiberglass Product

Selecting the appropriate welding blanket depends on your specific needs:

- Temperature rating:Match the blanket's maximum temperature to your welding process

- Thickness:Thicker blankets (like 1/8") offer more protection but are less flexible

- Size:Ensure coverage for your work area with standard or custom sizes

- Coating:Some fiberglass blankets have silicone coatings for extra durability

- Edge treatment:Look for reinforced edges with grommets for hanging

Proper Use and Maintenance of Your Welding Blanket

To get the most from your fiberglass welding blanket:

- Inspect for damage before each use

- Keep away from sharp edges that could tear the material

- Store in a clean, dry place when not in use

- Clean with compressed air or gentle brushing - avoid harsh chemicals

- Replace when you notice significant wear or reduced protection

Welding Blanket Fiberglass vs. Other Materials

While fiberglass is popular, you might consider alternatives:

| Material | Max Temperature | Pros | Cons |

|---|---|---|---|

| Fiberglass | 1000°F+ | Affordable, flexible, widely available | Can irritate skin, less durable than some options |

| Silica | 1800°F+ | Higher heat resistance | More expensive, less flexible |

| Leather | 400°F | Durable, spark resistant | Lower heat tolerance, heavier |

Safety Considerations When Using Welding Blankets

Remember these safety tips with your fiberglass welding blanket:

- Always wear proper PPE (gloves, goggles) when handling

- Never use as personal protective equipment - it's for surface protection only

- Keep away from electrical sources unless specifically rated

- Allow blankets to cool completely before moving or storing

- Have a fire extinguisher nearby when welding

Applications Beyond Welding for Fiberglass Blankets

Your welding blanket fiberglass product has multiple uses:

- Grinding operations

- Foundry work

- Fireplace protection

- Automotive repair

- HVAC ductwork

- Hot pipe insulation

Where to Buy Quality Welding Blanket Fiberglass Products

Look for reputable suppliers that offer:

- Clear temperature ratings

- Certifications (like OSHA compliance)

- Customer reviews

- Reasonable return policies

Many welding supply stores and industrial safety retailers carry quality fiberglass welding blankets in various sizes.

Caring for Your Fiberglass Welding Blanket

Extend your blanket's lifespan with proper care:

- Shake out debris after each use

- Spot clean with mild detergent if needed

- Hang to dry completely before storage

- Fold carefully to prevent creasing that weakens fibers

- Store in a protective bag if available

Investing in a quality welding blanket fiberglass product protects your workspace and improves safety. Choose the right specifications for your applications, use it properly, and maintain it well for long-lasting performance.