Durable Cow Hide Welding Blankets: Protection for Extreme Heat & Sparks

Summary:Cow hide welding blankets provide superior heat resistance and durability for welding projects. These natural leather blankets protect surfaces from sparks, slag, and heat damage while lasting longer than synthetic alternatives.

Why Choose Cow Hide for Welding Protection?

When you need reliable protection during welding, cow hide welding blankets offer unique advantages. Unlike synthetic materials that can melt or degrade, natural leather withstands extreme temperatures up to 500°F (260°C). The dense fiber structure of cow hide resists sparks and molten metal splatter better than most manufactured fabrics.

Key Benefits of Cow Hide Welding Blankets

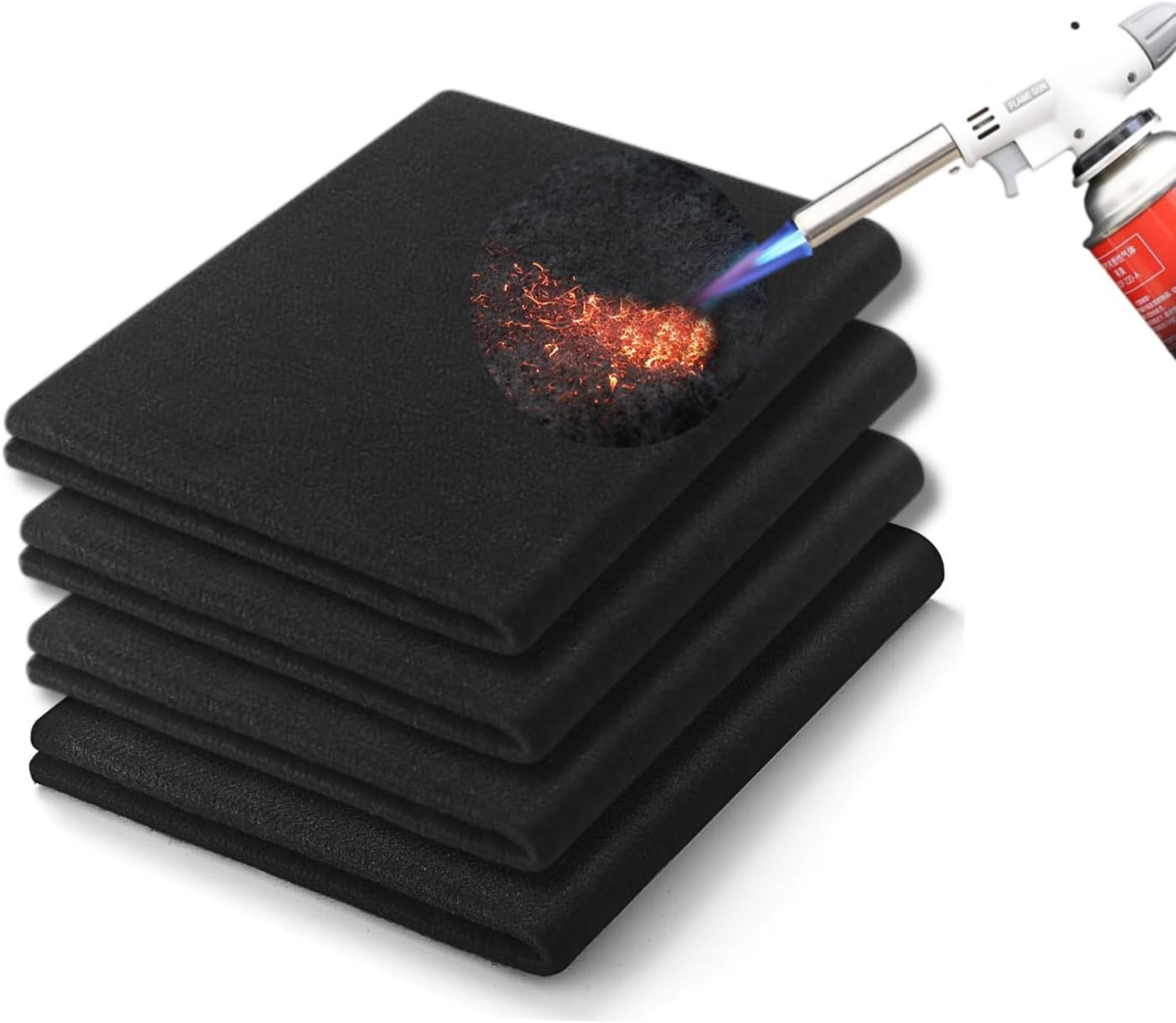

1. Superior Heat Resistance:Cow hide naturally insulates against heat transfer, protecting your work area and surrounding materials. The leather chars rather than burns when exposed to brief contact with extreme temperatures.

2. Exceptional Durability:These blankets last 3-5 times longer than fiberglass alternatives. The tough leather resists tearing and maintains its protective qualities even after years of use.

3. Spark and Slag Protection:Molten metal beads roll off cow hide surfaces instead of sticking or burning through. This prevents fire hazards and surface damage to floors or equipment.

Proper Use and Maintenance

To get the most from your cow hide welding blanket:

- Always position the smooth side facing upward to deflect sparks

- Overlap multiple blankets by at least 6 inches for complete coverage

- Store in a dry place when not in use to prevent mildew

- Clean with a stiff brush to remove slag buildup

- Condition annually with leather preservative to maintain flexibility

Comparing Cow Hide to Other Welding Blankets

While fiberglass and aluminized blankets have their uses, cow hide offers distinct advantages:

| Material | Max Temperature | Lifespan | Weight |

|---|---|---|---|

| Cow Hide | 500°F | 5-10 years | Heavy |

| Fiberglass | 1000°F | 1-3 years | Medium |

| Aluminized | 2000°F | 2-5 years | Light |

Applications for Cow Hide Welding Blankets

These versatile blankets work well for:

- Protecting wooden floors in auto shops

- Shielding delicate equipment near welding areas

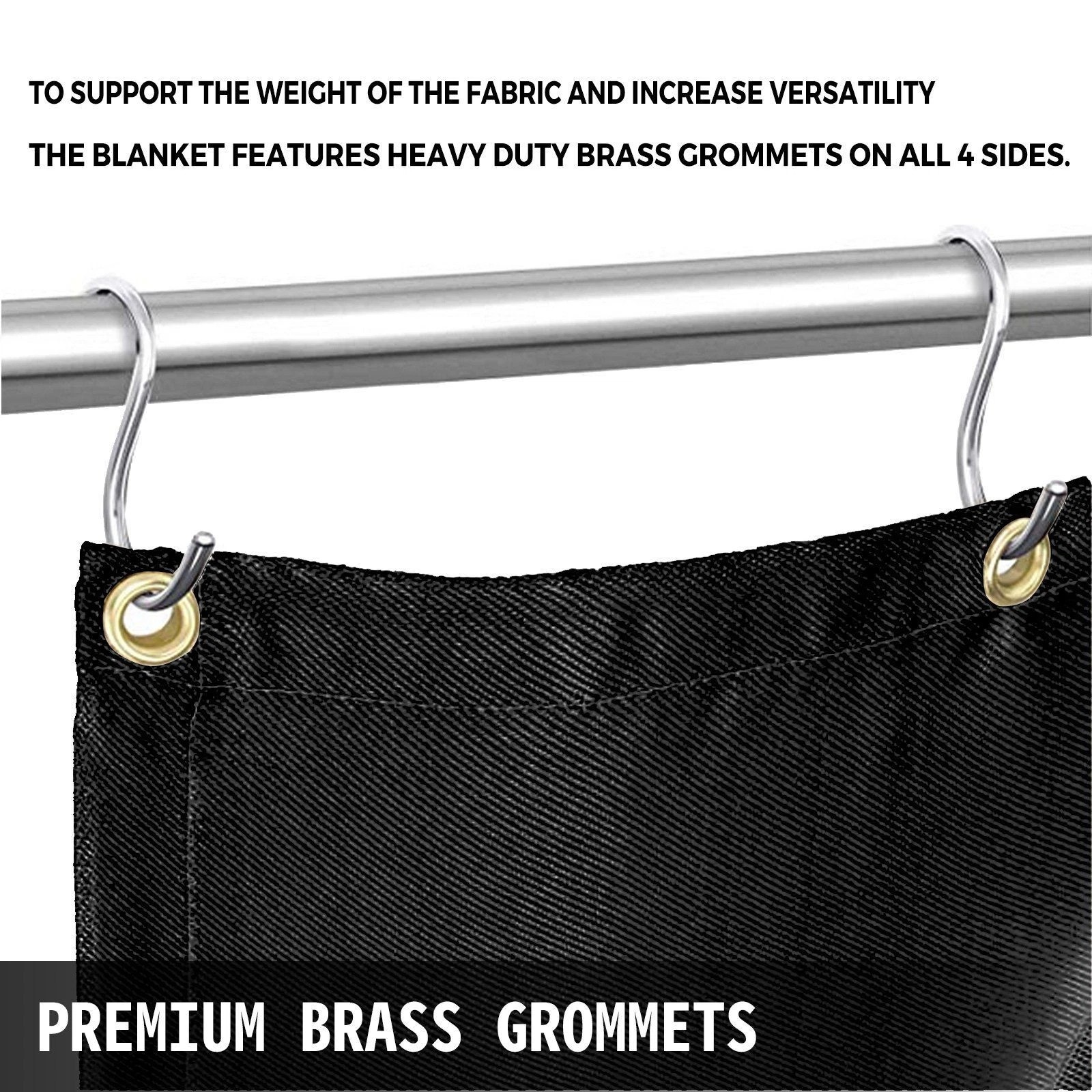

- Creating temporary welding curtains

- Covering vehicles during nearby welding operations

- Lining welding tables for easy cleanup

Safety Considerations

While cow hide welding blankets provide excellent protection, remember:

- Never leave blankets in contact with red-hot metal for extended periods

- Inspect regularly for thinning areas or excessive charring

- Replace if the leather becomes brittle or develops holes

- Always follow standard welding safety protocols

Choosing the Right Size

Standard cow hide welding blankets come in sizes from 4'x4' to 8'x8'. For most applications, a 6'x6' blanket provides adequate coverage. Measure your work area and add 12-18 inches of overlap on all sides for complete protection.

Cost vs. Value Analysis

While cow hide welding blankets cost more initially (typically $150-$400), their extended lifespan makes them more economical long-term. When you factor in replacement costs for cheaper alternatives, cow hide often proves the better investment for frequent welders.

Environmental Benefits

As a natural byproduct of the meat industry, cow hide welding blankets represent an eco-friendly choice. They're biodegradable at end-of-life, unlike synthetic blankets that contribute to landfill waste. Proper maintenance can extend their usefulness for decades.