Welding Heating Blankets: Essential Tools for Safe and Efficient Pipe Welding

Summary:Welding heating blankets provide controlled preheating and post-weld heat treatment for pipes and metal joints. They improve weld quality, prevent cracking, and ensure safety in industrial applications.

What Are Welding Heating Blankets?

Welding heating blankets are flexible thermal insulation tools designed for preheating and post-weld heat treatment (PWHT) of metal pipes and joints. You wrap them around the work area to maintain consistent temperatures before, during, and after welding. These specialized blankets help prevent thermal shock, reduce residual stresses, and minimize hydrogen-induced cracking in welds.

Why You Need Welding Heating Blankets

When you weld thick materials or certain alloys, sudden temperature changes can cause defects. Welding heating blankets solve this by:

- Providing uniform preheating (150-700°F typically)

- Maintaining interpass temperatures

- Allowing controlled cooling rates

- Protecting workers from burns

- Saving energy compared to open flames

Key Features of Quality Welding Heating Blankets

When choosing welding heating blankets, look for these essential features:

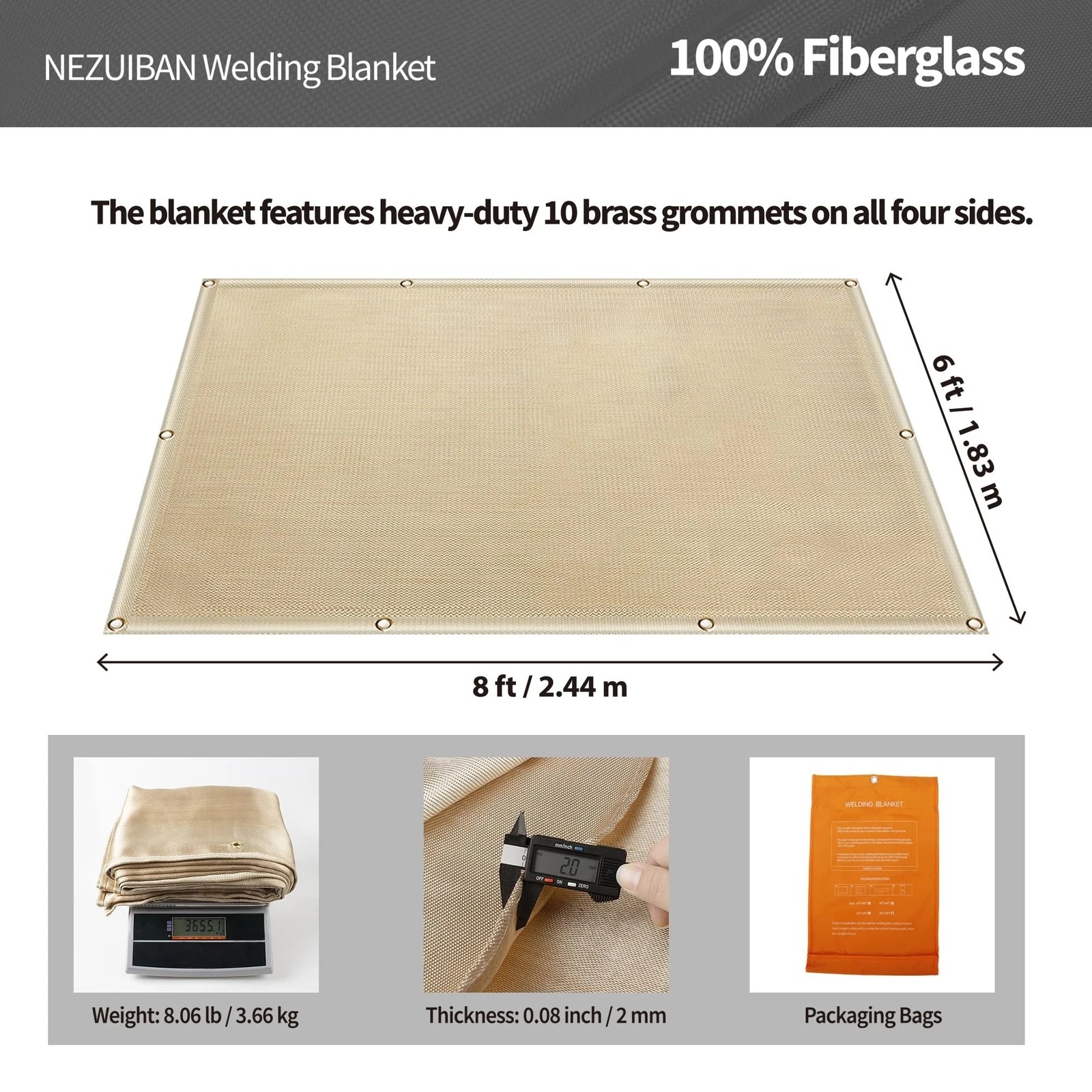

- Heat-resistant materials:Typically fiberglass or ceramic fiber construction

- Temperature range:Must match your application requirements

- Secure fastening:Hook-and-loop straps or lacing systems

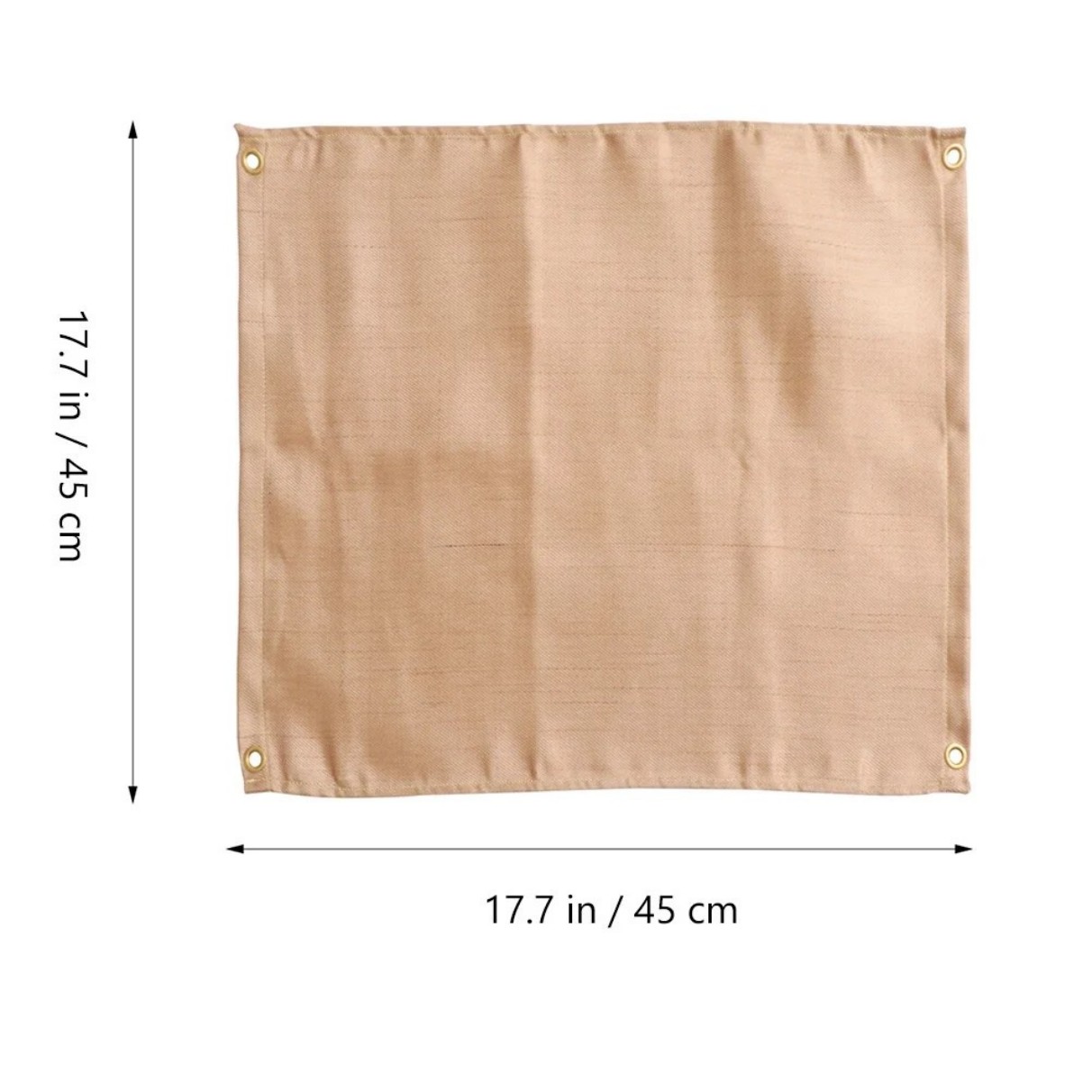

- Custom sizing:Available for different pipe diameters

- Durability:Resistant to weld spatter and mechanical damage

How to Use Welding Heating Blankets Properly

Follow these steps for effective use of welding heating blankets:

- Clean the pipe surface thoroughly

- Measure and record initial temperatures

- Wrap the blanket snugly around the joint area

- Secure all fasteners properly

- Monitor temperatures with thermocouples

- Maintain heat as specified by welding procedure

- Allow controlled cooling when complete

Common Applications of Welding Heating Blankets

You'll find welding heating blankets used in these critical industries:

- Oil and gas pipelines:For girth welds in field construction

- Power plants:Boiler tube and steam line welding

- Shipbuilding:Thick plate welding applications

- Structural steel:High-strength steel connections

- Process piping:Chemical and refinery piping systems

Safety Considerations

While welding heating blankets improve safety, you should still:

- Wear proper PPE (gloves, face shield)

- Check for electrical hazards

- Ensure proper ventilation

- Inspect blankets regularly for damage

- Follow manufacturer's temperature limits

Maintenance and Storage

To extend the life of your welding heating blankets:

- Clean after each use with compressed air

- Store flat or rolled (not folded)

- Keep in dry conditions

- Repair small tears immediately

- Replace when insulation shows significant wear

Choosing the Right Welding Heating Blanket

Consider these factors when selecting welding heating blankets:

- Material thickness and type

- Required preheat/interpass temperatures

- Pipe diameter or joint configuration

- Environmental conditions (outdoor/indoor)

- Regulatory requirements (ASME, AWS, etc.)

Conclusion

Welding heating blankets are essential for quality welds in critical applications. By providing controlled heating and insulation, they help you achieve code-compliant results while improving worksite safety. Invest in quality blankets matched to your specific needs, and follow proper procedures for best results.