4 x 6 Welding Blanket: Ultimate Protection for Your Workspace

A 4 x 6 welding blanket provides essential heat and spark protection for welding projects. This guide covers its benefits, materials, proper usage, and maintenance to help you work safely and efficiently.

Why Choose a 4 x 6 Welding Blanket?

When you're working with welding equipment, protection is crucial. A 4 x 6 welding blanket offers the perfect balance between coverage and maneuverability. This medium-sized blanket (4 feet by 6 feet) protects surfaces from sparks, slag, and heat up to 2000°F while being easy to handle.

The dimensions make it versatile for various applications:

- Covering workbenches or floors in home workshops

- Protecting vehicle interiors during auto repairs

- Shielding walls and equipment in professional shops

- Creating safe welding zones in temporary locations

Material Options for 4 x 6 Welding Blankets

Quality welding blankets come in different materials, each with advantages:

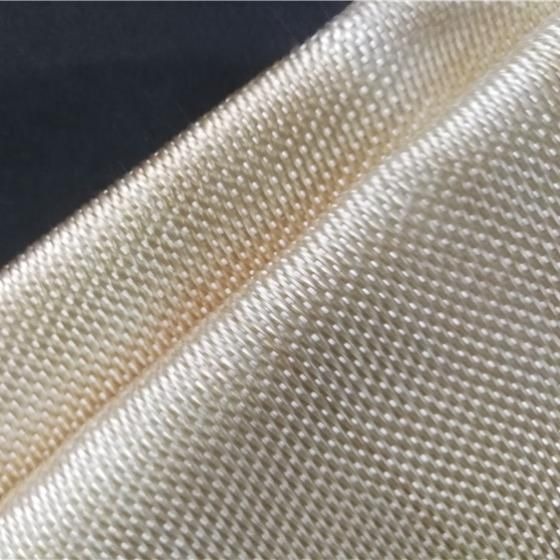

Fiberglass

The most common choice, fiberglass 4 x 6 welding blankets resist temperatures up to 1000°F. They're flexible, lightweight, and affordable. Look for silicone-coated versions for better durability.

Carbon Fiber

For extreme heat (up to 2000°F), carbon fiber blankets offer superior protection. They're more expensive but last longer in professional settings.

Ceramic Fiber

These specialized blankets handle ultra-high temperatures (over 2000°F) and are ideal for foundry work or plasma cutting.

Proper Use of Your 4 x 6 Welding Blanket

To maximize safety and blanket longevity:

- Inspect before each use for tears or thin spots

- Secure edges with weights or clamps to prevent shifting

- Overlap multiple blankets for larger coverage areas

- Keep flammable materials away from covered surfaces

- Allow proper ventilation when covering enclosures

Maintenance and Care Tips

Your 4 x 6 welding blanket will last longer with proper care:

- Shake off debris after each use

- Hand wash with mild detergent when needed

- Hang to dry completely before storage

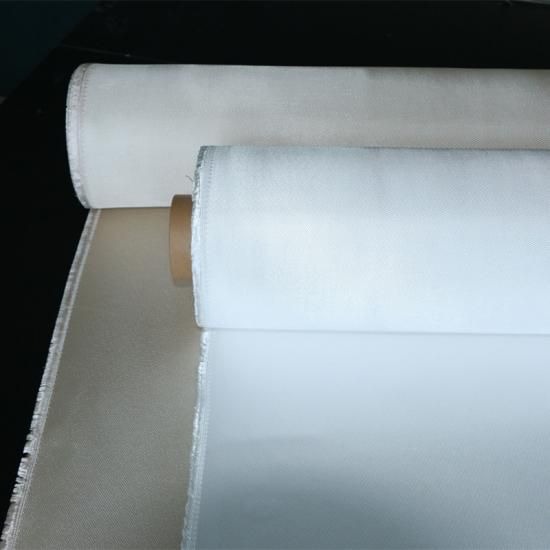

- Store flat or rolled (never folded) to prevent crease damage

- Replace when fibers become brittle or coverage diminishes

Choosing the Right 4 x 6 Welding Blanket

Consider these factors when purchasing:

| Feature | What to Look For |

|---|---|

| Temperature Rating | Matches your typical welding temperatures |

| Edge Treatment | Reinforced edges prevent fraying |

| Weight | Heavier blankets stay in place better |

| Certifications | Look for OSHA or ANSI compliance |

Creative Uses Beyond Welding

While designed for welding, your 4 x 6 blanket can also:

- Protect surfaces during grinding or cutting

- Serve as emergency heat shielding

- Create a fire-resistant work area for soldering

- Line forge or foundry equipment

Safety First: Limitations to Remember

While extremely useful, 4 x 6 welding blankets have limits:

- Not a substitute for proper PPE (always wear gloves/face shields)

- Don't use as primary fire containment for large sparks

- Avoid direct contact with molten metal

- Never leave unattended when covering hot materials

Investing in a quality 4 x 6 welding blanket protects your workspace and equipment while making your projects safer and more efficient. Choose the right material for your needs, maintain it properly, and it will serve you well for years.