Top Welding Blanket Manufacturers for Safety & Heat Protection

Welding blankets protect workers and equipment from sparks, heat, and molten metal. This guide covers leading welding blanket manufacturers, key features to consider, and how to choose the right product for your needs.

Why You Need a Quality Welding Blanket

Welding blankets are essential safety tools in any workshop or construction site. They shield surfaces from:

- Flying sparks (up to 2,000°F/1,093°C)

- Molten metal splatter

- Radiant heat transfer

- Accidental fire spread

Reputable welding blanket manufacturers use fiberglass, silica, or ceramic materials that won't burn or conduct electricity.

Top 5 Welding Blanket Manufacturers

1. Thermal Products Company

This US-based manufacturer offers industrial-grade blankets with:

- Temperature resistance up to 2,500°F (1,371°C)

- Reinforced stitching and grommets

- Custom sizing options

2. Textile Technologies Inc.

Specializing in silica fabric blankets that:

- Remain flexible in extreme cold

- Provide excellent abrasion resistance

- Come with OSHA-compliant certifications

3. Shree Firepack Safety Pvt. Ltd.

A global supplier known for:

- Cost-effective fiberglass solutions

- Quick turnaround on bulk orders

- Wide range of thicknesses (1/16" to 1/4")

4. Newtex Industries

Their Zetex® line features:

- Proprietary ceramic fiber technology

- Low thermal conductivity

- Chemical splash protection

5. National Safety Apparel

Offers welding blankets with:

- Bright safety colors for visibility

- Lightweight options (under 1 lb/sq ft)

- Welding curtain configurations

Key Features to Compare

When evaluating welding blanket manufacturers, consider:

| Feature | Entry-Level | Professional Grade |

|---|---|---|

| Max Temperature | 1,000°F (538°C) | 2,500°F+ (1,371°C+) |

| Material | Fiberglass | Silica/Ceramic |

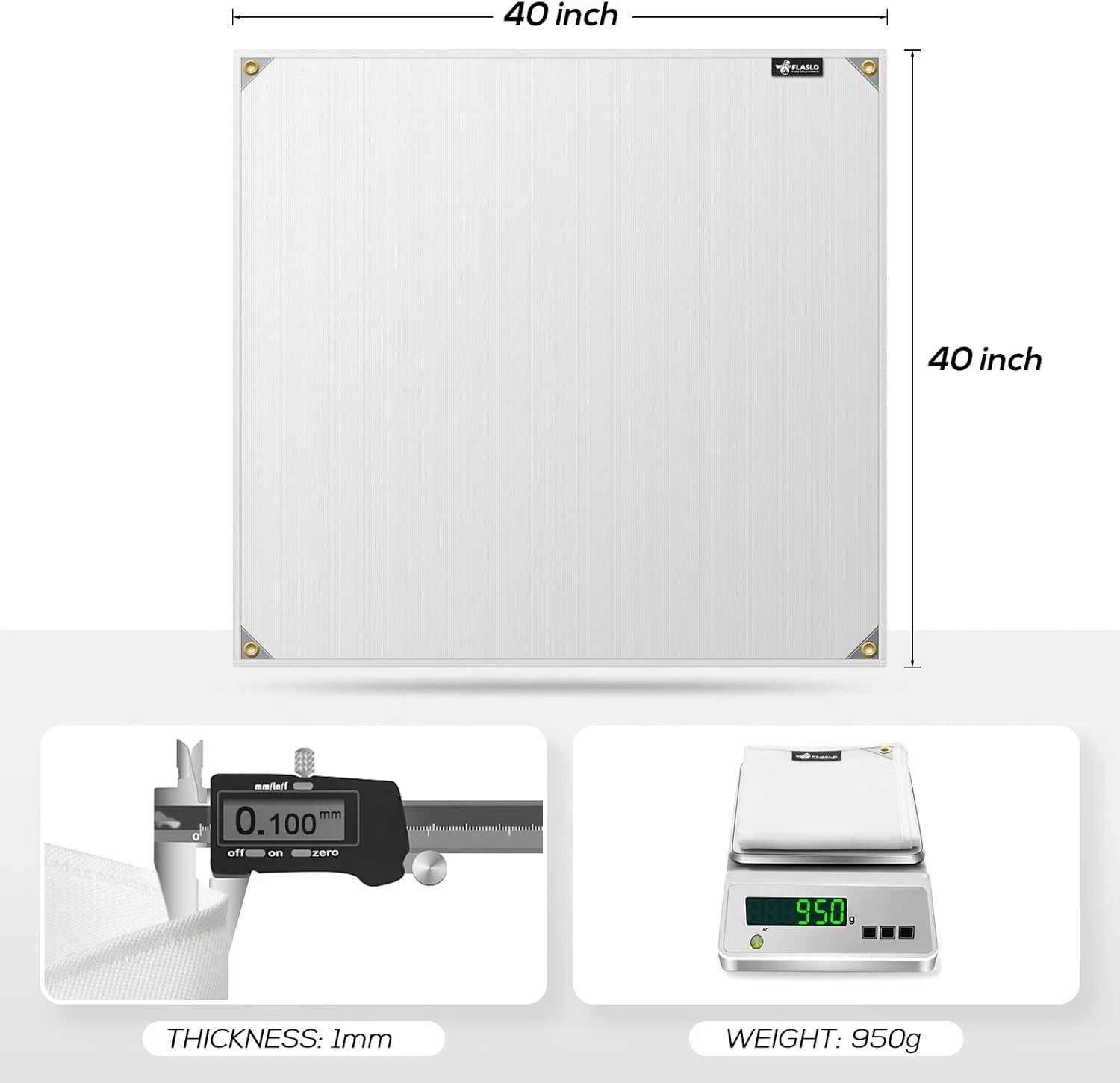

| Thickness | 1/16" (1.6mm) | 1/4" (6.4mm) |

| Certifications | None | OSHA, NFPA |

How to Choose Your Manufacturer

Follow this decision process:

- Assess your needs:Consider your typical welding temperatures and project sizes

- Compare materials:Fiberglass works for most applications, while silica handles extreme heat

- Check certifications:Look for NFPA 701 (fire resistance) and OSHA compliance

- Evaluate durability:Grommets and reinforced edges extend product life

- Request samples:Reputable welding blanket manufacturers often provide material swatches

Maintenance Tips

Proper care extends your welding blanket's lifespan:

- Shake off slag and debris after each use

- Store flat or rolled (never folded) to prevent crease damage

- Wash only when necessary using mild detergent

- Inspect for tears or thin spots monthly

- Replace when more than 10% surface shows wear

Industry Applications

Beyond welding, these blankets serve:

- Foundries:Covering molten metal pours

- Power plants:Insulating hot pipes

- Aerospace:Protecting sensitive components during repairs

- Automotive:Shielding paintwork during exhaust work

Leading welding blanket manufacturers understand these diverse applications and engineer their products accordingly. Whether you need basic spark protection or extreme heat resistance, investing in quality blankets from reputable suppliers ensures safety and cost-effectiveness in the long run.