Essential Guide to Solder Weld Blankets: Safety & Efficiency in Welding

Summary:Solder weld blankets protect surfaces from heat and sparks during welding. This guide explains their materials, uses, safety benefits, and how to choose the right one for your projects.

What Is a Solder Weld Blanket?

When you're welding or soldering, heat and sparks can damage nearby surfaces. A solder weld blanket is your first line of defense. These specialized covers are made from heat-resistant materials that withstand extreme temperatures while protecting your work area.

Unlike regular blankets, solder weld blankets are engineered for welding environments. They typically consist of fiberglass, silica, or ceramic fabrics that won't melt or catch fire when exposed to welding sparks. The best ones offer both protection and flexibility.

Key Benefits of Using Solder Weld Blankets

1. Surface Protection:They prevent burn marks on floors, furniture, or equipment near your workspace. Even accidental contact with hot metal won't damage covered surfaces.

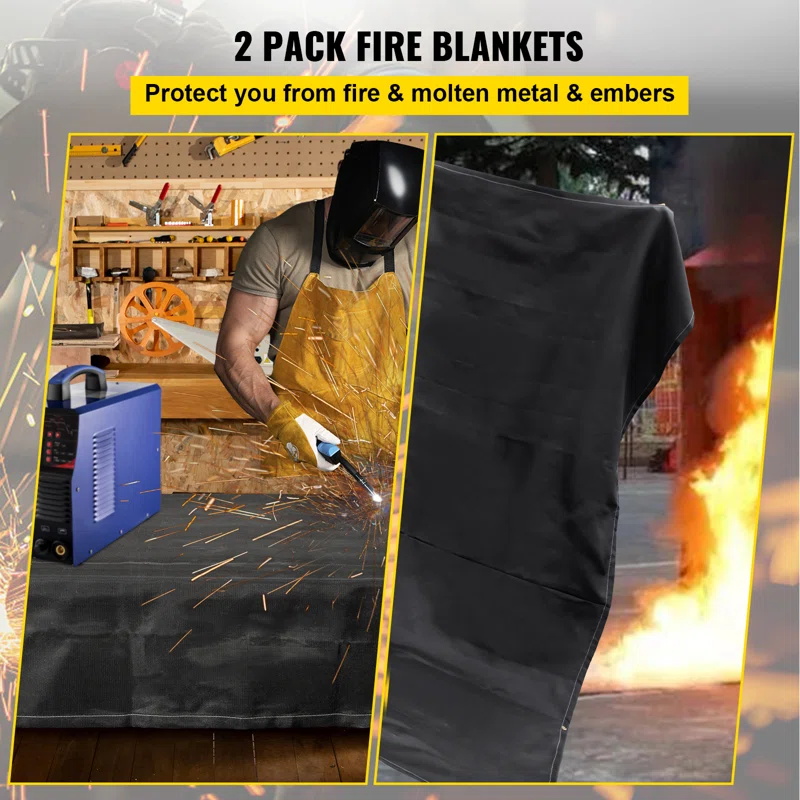

2. Fire Prevention:By containing sparks and molten metal splatter, these blankets significantly reduce fire risks in your workshop or job site.

3. Improved Efficiency:With protected surfaces, you can focus on welding rather than constantly worrying about collateral damage. This leads to better work quality.

4. Versatility:Beyond welding, these blankets work for soldering, grinding, and other high-heat applications where surface protection matters.

Choosing the Right Solder Weld Blanket

Not all weld blankets are equal. Consider these factors when selecting yours:

Material:Fiberglass blankets (most common) handle temperatures up to 1000°F. Silica models withstand up to 1800°F, while ceramic options exceed 2000°F for heavy-duty welding.

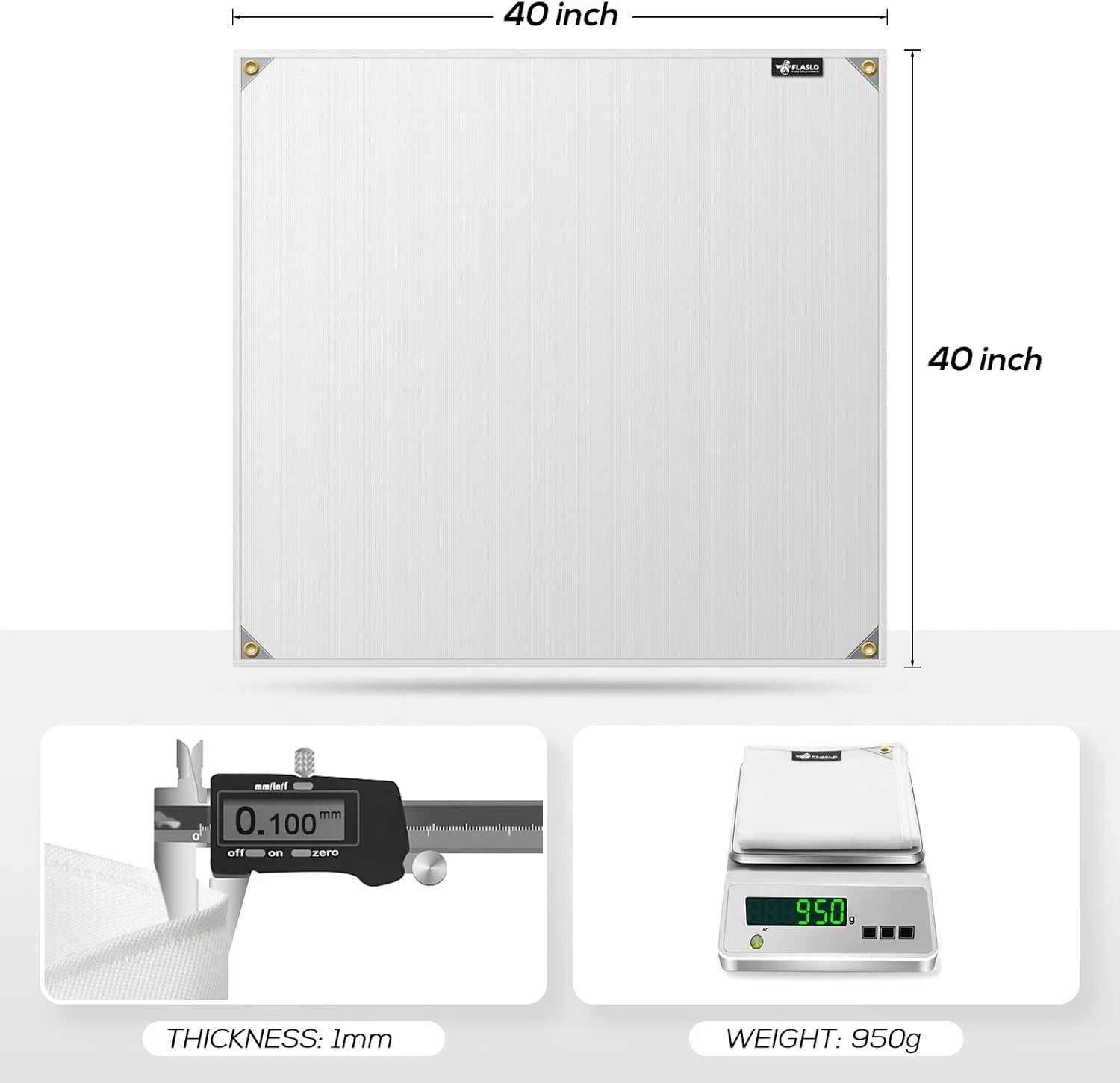

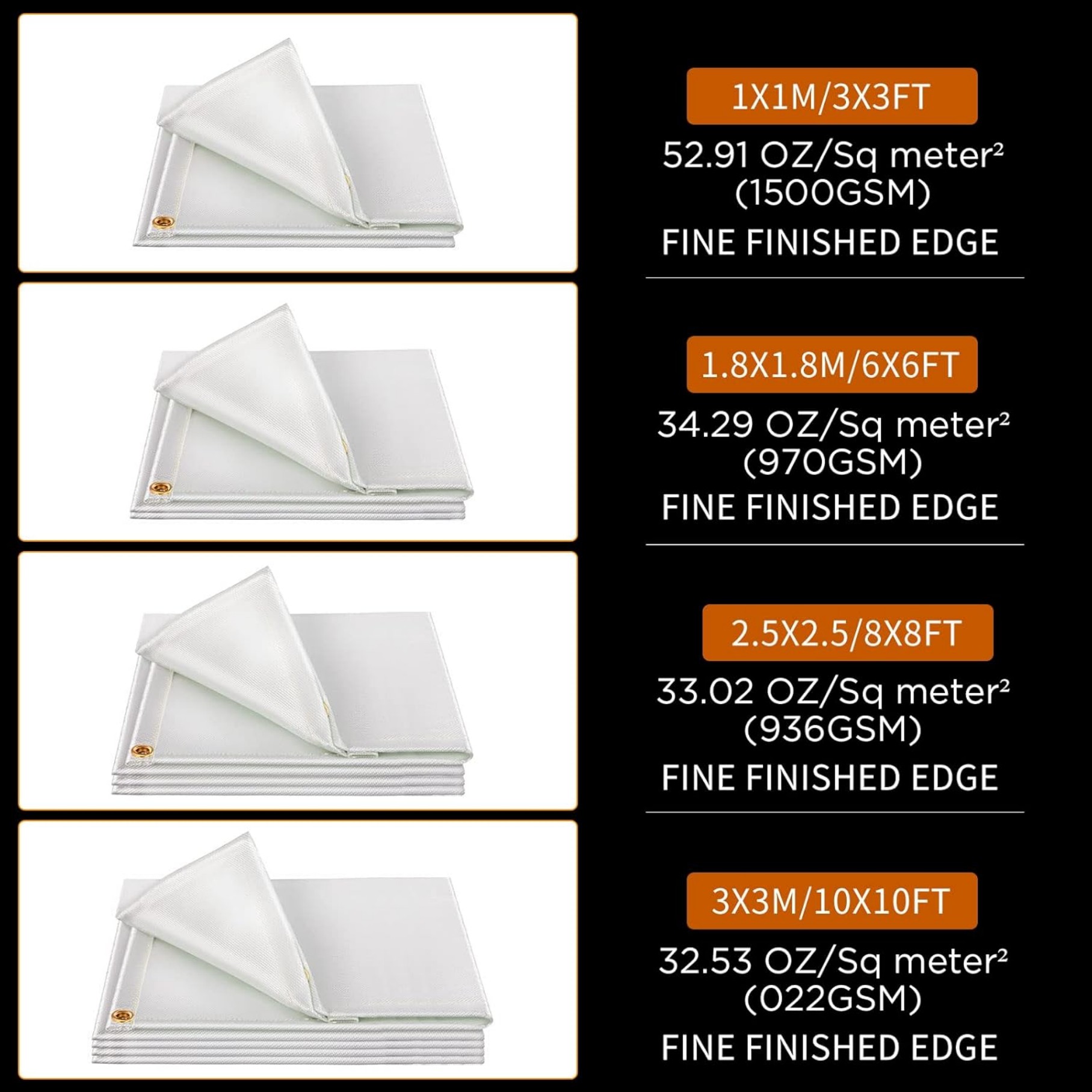

Size:Measure your work area. Standard sizes range from 3'x3' for small jobs to 6'x8' for large projects. Some manufacturers offer custom sizing.

Thickness:Thicker blankets (1/8" or more) provide better protection but are less flexible. Thinner options work for light soldering tasks.

Edge Treatment:Look for reinforced edges with grommets if you need to secure the blanket in place. Some models include hook-and-loop fasteners.

Proper Use and Maintenance

To get the most from your solder weld blanket:

1. Always inspect for damage before use - replace if you see holes or frayed edges

2. Cover the entire work area, extending at least 12 inches beyond your welding zone

3. For vertical surfaces, secure the blanket with non-flammable fasteners

4. Clean regularly by shaking off debris or gently vacuuming (never wash fiberglass blankets)

5. Store flat or rolled - avoid folding to prevent material fatigue

Safety Considerations

While solder weld blankets improve safety, remember:

- They don't replace proper ventilation or personal protective equipment

- Never use damaged blankets - their protective qualities diminish with wear

- Keep flammable materials away even when using a blanket

- Allow blankets to cool completely before moving or storing

Alternative Uses Beyond Welding

Your solder weld blanket has multiple applications:

Automotive Work:Protect car interiors during exhaust repairs or engine work

Home Projects:Shield floors during pipe soldering or fireplace maintenance

Emergency Situations:Can serve as a temporary heat shield in some cases

Art Projects:Useful for protecting surfaces during metal art creation

Investing in Quality

Cheap solder weld blankets may seem attractive, but quality matters. Premium blankets:

- Last 3-5 times longer than budget options

- Provide consistent protection throughout their lifespan

- Often come with better edge reinforcement

- May include useful features like measurement markings

Consider your usage frequency and the value of what you're protecting. For professional welders, investing in commercial-grade blankets pays off quickly.

Conclusion

A solder weld blanket is more than just a protective cover - it's an essential safety tool that improves your work quality and protects valuable surfaces. By choosing the right blanket and using it properly, you create a safer, more efficient workspace for all your welding and soldering projects.