10x10 Welding Blanket - Fireproof Protection for Safe Welding

This guide explains why a 10x10 welding blanket is essential for welding safety. You'll learn about materials, heat resistance, proper usage, and how it protects your workspace from sparks and molten metal.

What Is a 10x10 Welding Blanket?

A 10x10 welding blanket is a square-shaped protective cover measuring 10 feet by 10 feet. It's made from fire-resistant materials that withstand extreme heat from welding, cutting, and grinding operations. When you're working with hot metal, this blanket creates a safe barrier between your work area and flammable surfaces.

Key Features of Quality 10x10 Welding Blankets

Look for these essential characteristics when choosing your 10x10 welding blanket:

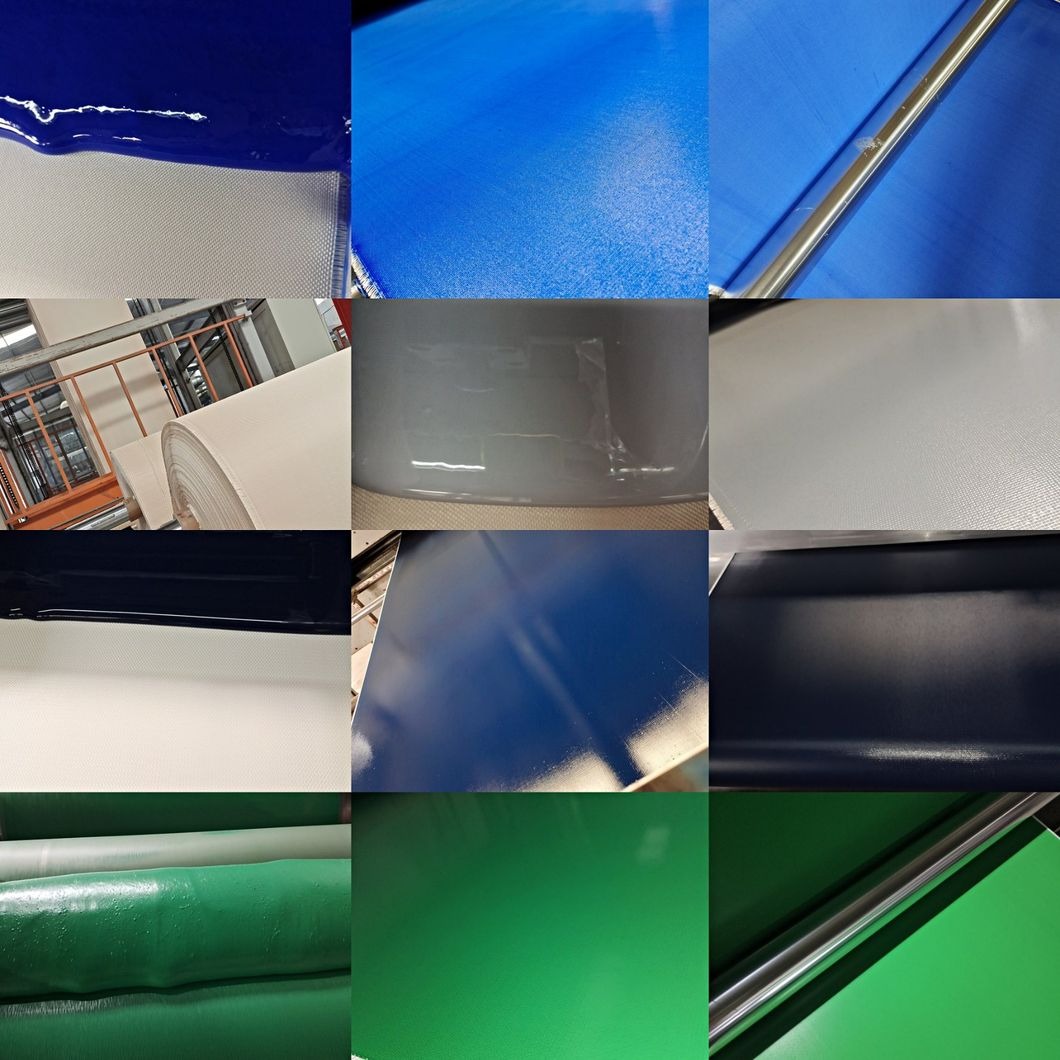

- Fiberglass construction:Most professional-grade blankets use fiberglass fabric with silicone coating

- Temperature resistance:Should withstand at least 1000°F (538°C), with some models rated to 2000°F

- Reinforced edges:Metal grommets allow secure hanging or fastening

- Flexibility:The material should remain pliable in cold weather

- No toxic fumes:Must not produce harmful smoke when exposed to sparks

Why Size Matters: Benefits of 10x10 Dimensions

The 10x10 welding blanket offers ideal coverage for most welding projects. This size gives you enough protection for:

- Covering standard workbenches (typically 8 feet long)

- Protecting floors beneath welding tables

- Creating temporary welding curtains

- Shielding vehicles during mobile repair work

Smaller blankets may leave gaps in protection, while larger ones become cumbersome to handle. The 10x10 size balances coverage with practicality.

Proper Use of Your 10x10 Welding Blanket

To get maximum protection from your welding blanket:

- Inspect for damage before each use - replace if you see holes or fraying

- Secure all edges - use the grommets to tie down or weigh down corners

- Overlap multiple blankets for larger areas - maintain at least 6-inch overlaps

- Keep away from open flames - while fire-resistant, prolonged direct flame can damage the material

- Store properly - fold neatly and keep in a dry place away from sharp objects

Maintenance and Care Tips

With proper care, your 10x10 welding blanket will last for years:

- Cleaning:Shake off debris regularly. For deep cleaning, use compressed air or a soft brush

- Repairs:Small holes can be patched with high-temperature silicone tape

- Storage:Hang vertically or fold loosely to prevent creases that could weaken the material

- Replacement:Replace when more than 10% of the surface shows significant wear

Safety Considerations

While 10x10 welding blankets provide excellent protection, remember:

- They don't replace proper personal protective equipment (PPE) like gloves and face shields

- Never use them as personal fire blankets - they're designed for equipment protection

- Keep a fire extinguisher nearby when welding, even with blanket protection

- Monitor heat buildup - extremely hot metal can transfer heat through the blanket over time

Choosing the Right 10x10 Welding Blanket

Consider these factors when purchasing:

| Feature | Basic | Professional | Industrial |

|---|---|---|---|

| Material | Fiberglass | Silicone-coated fiberglass | Multi-layer composite |

| Max Temperature | 1000°F | 1500°F | 2000°F+ |

| Thickness | 1/16" | 1/8" | 1/4" |

For occasional home use, a basic 10x10 welding blanket suffices. Professional welders should invest in silicone-coated models, while industrial applications need heavy-duty options.

Common Applications

Beyond welding, your 10x10 blanket works well for:

- Grinding operations

- Foundry work

- Fireplace protection

- Hot work in construction

- Automotive exhaust work

Its versatility makes the 10x10 welding blanket a valuable addition to any workshop.