Aluminum Welding Wire Blanket: Essential Guide for Welders & DIY Enthusiasts

This guide explains aluminum welding wire blankets - their purpose, benefits, and proper usage. You'll learn how they protect your workspace and improve welding quality when working with aluminum wires.

What Is an Aluminum Welding Wire Blanket?

An aluminum welding wire blanket is a specialized protective covering designed for welding applications. It serves as a heat-resistant barrier that protects surfaces from sparks, spatter, and molten metal during aluminum welding projects. Unlike regular blankets, these are made from materials that can withstand extreme temperatures up to 2000°F (1093°C).

When you're working with aluminum welding wire, the blanket becomes essential because aluminum requires different handling than steel. The material's high thermal conductivity means heat spreads quickly, increasing fire risks. The welding wire blanket contains these hazards while you work.

Key Benefits of Using Aluminum Welding Wire Blankets

Using the right protective equipment makes your welding projects safer and more efficient. Here's why professionals rely on aluminum welding wire blankets:

- Fire Prevention:Aluminum sparks can travel farther than steel sparks. The blanket contains them effectively.

- Surface Protection:Prevents damage to floors, workbenches, and nearby equipment from molten metal.

- Heat Containment:Helps maintain consistent welding temperatures by reducing heat loss to surroundings.

- Reusable:High-quality blankets withstand multiple uses, making them cost-effective.

- Portable:Lightweight and flexible for use in various work environments.

Choosing the Right Aluminum Welding Wire Blanket

Not all welding blankets are equal. For aluminum work, consider these factors:

Material Composition:Look for fiberglass or silica-based fabrics with aluminum coating. These provide the best protection against aluminum's unique welding characteristics.

Temperature Rating:Ensure the blanket's maximum temperature rating exceeds your welding parameters. Aluminum welding typically requires blankets rated for at least 1500°F (815°C).

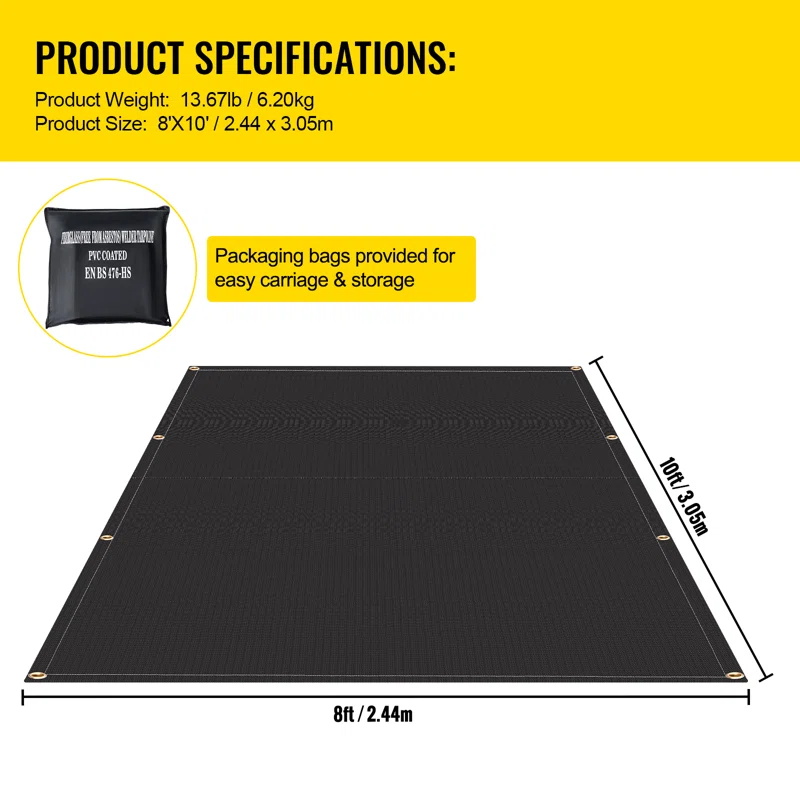

Size and Thickness:Choose dimensions that cover your work area adequately. Thicker blankets (1/8" or more) offer better protection for intensive aluminum welding.

Edge Treatment:Reinforced edges with grommets allow for secure placement and longer service life.

Proper Use and Maintenance

To get the most from your aluminum welding wire blanket:

- Inspect before each use for tears or excessive wear

- Position it to cover all vulnerable surfaces within 35 feet of your work area

- Secure it properly to prevent movement during welding

- Allow complete cooling before handling or folding

- Clean with compressed air or soft brush - never use water

- Store flat or rolled in a dry, clean space

Common Applications

Aluminum welding wire blankets are versatile tools used in:

- Automotive repair (aluminum body panels, frames)

- Aerospace manufacturing and maintenance

- Marine applications (aluminum hulls and components)

- Architectural metalwork

- DIY projects with aluminum materials

Safety Considerations

While aluminum welding wire blankets significantly improve safety, remember:

- They supplement - don't replace - personal protective equipment (PPE)

- Never use damaged blankets - replace them immediately

- Keep flammable materials away even when using blankets

- Monitor for heat buildup in confined spaces

- Follow all standard welding safety protocols

Conclusion

An aluminum welding wire blanket is an indispensable tool for anyone working with aluminum welding wires. It provides crucial protection against fire hazards and surface damage while improving your working conditions. By choosing the right blanket and using it properly, you ensure safer, more efficient aluminum welding projects with professional results.