Carbon Fiber Weld Blanket: Ultimate Protection for High-Temperature Welding

Carbon fiber weld blankets provide superior heat protection during welding operations. These specialized covers resist extreme temperatures, prevent fire hazards, and protect surrounding areas from sparks and molten metal splatter. Learn how they outperform traditional welding blankets.

What Is a Carbon Fiber Weld Blanket?

A carbon fiber weld blanket is a high-temperature resistant fabric designed specifically for welding applications. Unlike standard welding blankets made from fiberglass or silica, carbon fiber versions offer exceptional thermal protection up to 2000°F (1093°C). The unique carbon fiber construction provides both flexibility and durability.

Key Benefits of Using Carbon Fiber Weld Blankets

- Extreme heat resistance:Withstands temperatures that would melt or burn traditional materials

- Non-combustible:Won't catch fire or contribute to flame spread

- Excellent thermal insulation:Protects nearby surfaces and materials from heat damage

- Spark and slag protection:Contains welding sparks and prevents burn-through

- Chemical resistance:Impervious to most acids, alkalis, and solvents

- Durable and reusable:Lasts significantly longer than fiberglass alternatives

How Carbon Fiber Weld Blankets Work

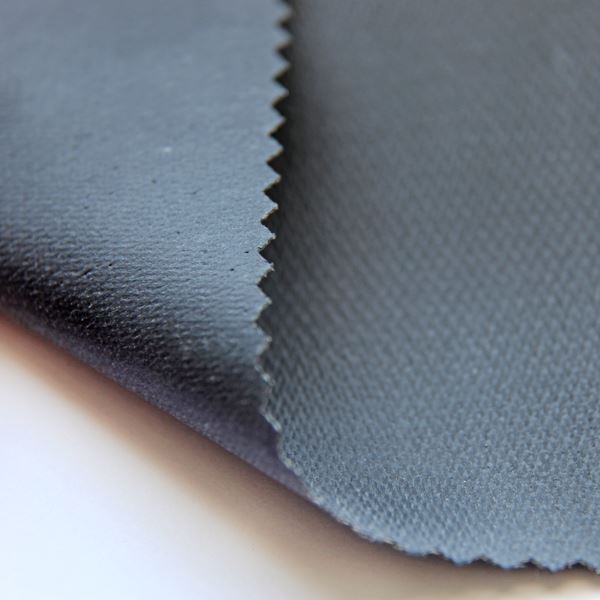

The secret to carbon fiber weld blankets lies in their unique material composition. Carbon fibers are woven into a tight matrix that reflects radiant heat while providing excellent thermal insulation. When sparks or molten metal contact the blanket, the carbon fibers absorb and dissipate the heat without degrading.

Pro Tip:Always choose a carbon fiber weld blanket slightly larger than your work area to ensure complete coverage and protection from stray sparks.

Applications of Carbon Fiber Weld Blankets

These versatile protective covers have numerous industrial and commercial uses:

- Welding shops:Protecting floors, walls, and equipment during arc welding, MIG, TIG, and plasma cutting

- Shipbuilding:Containing sparks in confined spaces where fire risk is high

- Automotive repair:Shielding sensitive components during frame welding

- Construction:Protecting finished surfaces during metal fabrication on-site

- Aerospace:Safeguarding aircraft components during maintenance welding

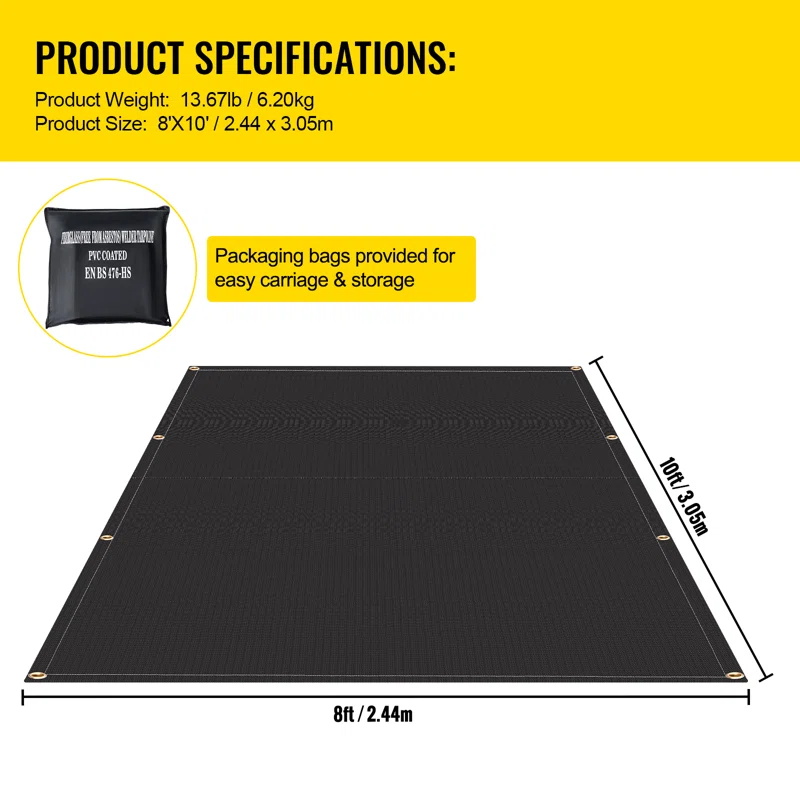

Choosing the Right Carbon Fiber Weld Blanket

Consider these factors when selecting your welding blanket:

- Temperature rating:Match the blanket's maximum temperature to your welding process

- Size:Measure your work area and add safety margins

- Thickness:Thicker blankets offer better protection but may be less flexible

- Edge treatment:Look for reinforced edges for durability

- Attachment options:Some models include grommets or hooks for secure placement

Proper Use and Maintenance

To get the most from your carbon fiber weld blanket:

- Inspect before each use for tears or excessive wear

- Position the blanket to cover all vulnerable areas completely

- Secure edges to prevent movement during work

- Clean with compressed air or a soft brush - avoid harsh chemicals

- Store flat or rolled - never fold sharply as this can damage fibers

Carbon Fiber vs. Traditional Welding Blankets

While fiberglass welding blankets are common, carbon fiber offers distinct advantages:

- Longer lifespan:Carbon fiber doesn't degrade as quickly from heat exposure

- Better protection:Higher temperature resistance prevents burn-through

- Cleaner operation:Doesn't shed fibers like fiberglass alternatives

- More flexible:Maintains pliability even after repeated high-heat exposure

Safety Considerations

While carbon fiber weld blankets significantly improve safety, remember:

- Always wear appropriate personal protective equipment (PPE)

- Never use a damaged blanket - replace immediately if compromised

- Keep flammable materials away from welding areas, even when using a blanket

- Allow the blanket to cool completely before moving or storing

- Follow all standard welding safety protocols in addition to using the blanket

Conclusion

A carbon fiber weld blanket is an essential safety tool for any serious welding operation. Its superior heat resistance, durability, and protective qualities make it worth the investment over traditional options. By choosing the right blanket and using it properly, you'll create a safer work environment while protecting valuable equipment and surfaces from welding hazards.