How to Use a Welding Blanket Safely for Heat Protection

Summary:A welding blanket protects surfaces from sparks and heat. Learn proper setup, material selection, and safety tips to maximize protection during welding projects. This guide covers essential techniques for effective use.

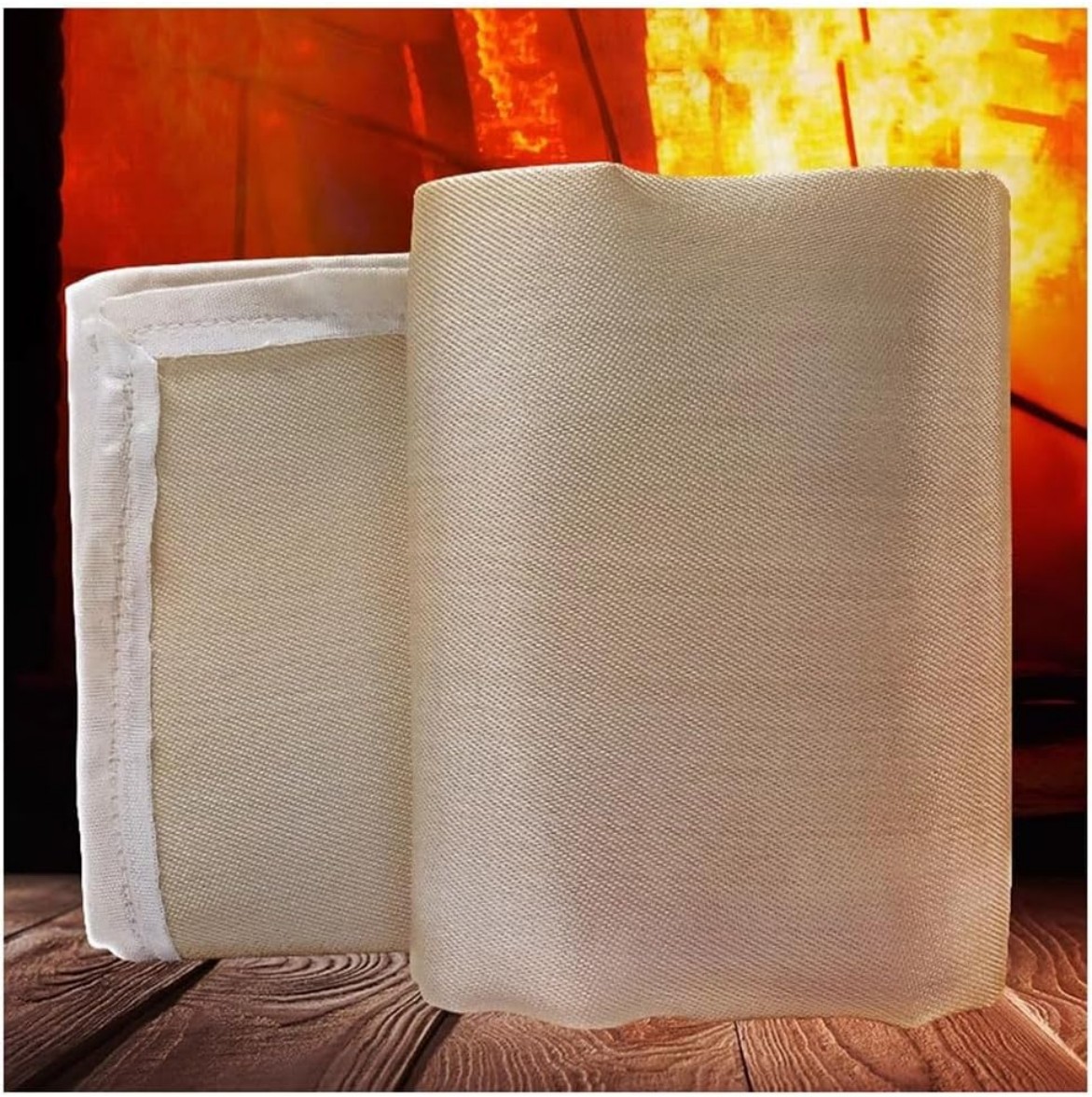

What Is a Welding Blanket?

A welding blanket is a heat-resistant fabric that shields nearby objects from sparks, slag, and radiant heat during welding. Made from materials like fiberglass or silica, these blankets can withstand temperatures up to 2,000°F (1,093°C). You'll find them essential for protecting floors, walls, and equipment in your workspace.

Choosing the Right Welding Blanket

When selecting a welding blanket, consider these factors:

- Material:Fiberglass blankets are common for general use, while silica offers higher heat resistance

- Thickness:Thicker blankets (1/4" or more) provide better protection for heavy-duty welding

- Size:Standard sizes range from 4'x6' to 8'12' - choose based on your work area

- Color coding:Some manufacturers use colors to indicate temperature ratings

Proper Setup Techniques

Using a welding blanket correctly ensures maximum protection:

- Clean the area before laying down the blanket to prevent debris from catching fire

- Drape the blanket over all nearby surfaces within 10 feet of your welding area

- Secure edges with non-flammable weights or clamps to prevent shifting

- Overlap multiple blankets by at least 6 inches if covering large areas

- Keep the blanket taut to prevent sagging where sparks could accumulate

Safety Precautions When Using a Welding Blanket

While welding blankets are designed for safety, proper handling is crucial:

- Always inspect for holes or thin spots before use

- Never use a wet blanket - moisture can cause steam burns

- Wear gloves when handling used blankets - they retain heat

- Keep flammable materials at least 3 feet away from the blanket's edges

- Replace blankets showing significant wear or carbonization

Maintenance and Care

Proper care extends your welding blanket's lifespan:

- Shake out debris after each use

- Store flat or rolled - never fold, as creases weaken fibers

- Clean with compressed air or a soft brush - avoid water

- Check for embedded sparks before storage

- Rotate blankets periodically to distribute wear evenly

Advanced Applications

Beyond basic spark protection, welding blankets have specialized uses:

- Containment:Create temporary welding curtains by hanging blankets vertically

- Multi-layer protection:Combine with fire-resistant boards for extreme heat

- Portable work surfaces:Lay blankets under portable welding tables

- Emergency repairs:Temporarily patch damaged furnace insulation

Common Mistakes to Avoid

Even experienced welders sometimes misuse blankets:

- Using blankets as primary PPE (they're for equipment protection, not personal)

- Covering ventilation openings in confined spaces

- Reusing blankets with accumulated slag deposits

- Storing near chemicals that could degrade the material

- Assuming all blankets have equal heat resistance

When to Replace Your Welding Blanket

Watch for these signs that your blanket needs replacement:

- Visible holes larger than 1/4 inch

- Stiff or brittle areas that crack when flexed

- Discoloration covering more than 30% of the surface

- Reduced flexibility that prevents proper draping

- Any signs of smoldering after use

By following these guidelines for using a welding blanket, you'll significantly improve worksite safety and protect valuable equipment. Always prioritize proper setup and regular inspection to maintain effective heat protection during all welding operations.