Heavy Duty Welding Blanket Guide: Protection, Uses & Buying Tips

Summary:Heavy duty welding blankets protect against sparks, heat, and molten metal. This guide explains their materials, uses, safety benefits, and how to choose the right one for your welding projects.

What Is a Heavy Duty Welding Blanket?

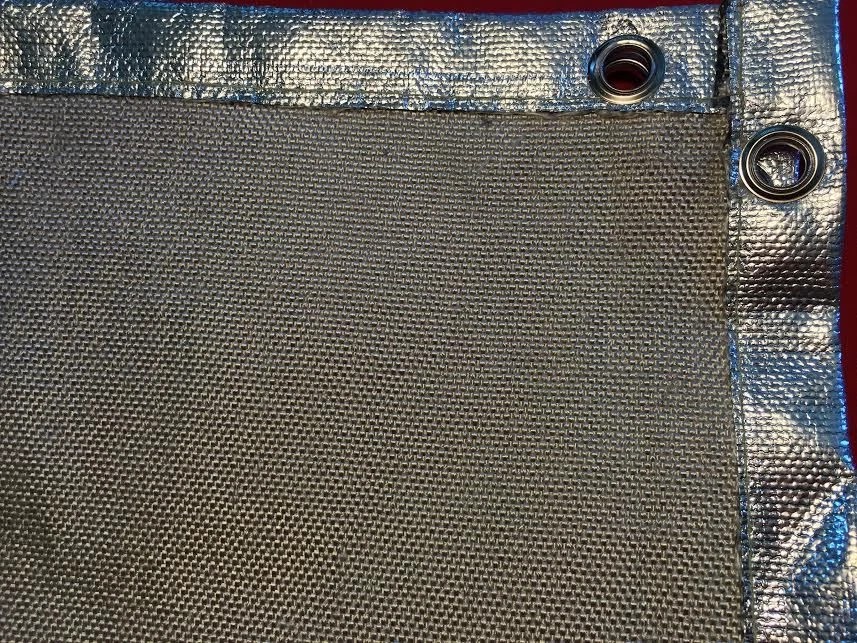

A heavy duty welding blanket is your first line of defense against welding hazards. These specialized covers are made from heat-resistant materials like fiberglass or silica to withstand extreme temperatures up to 2,500°F. Unlike regular tarps, they won't melt or catch fire when sparks land on them.

Key Benefits You Should Know

When you use a quality heavy duty welding blanket, you get three main advantages:

- Safety:Prevents fire accidents by containing sparks and slag

- Surface Protection:Keeps floors, walls, and equipment safe from heat damage

- Versatility:Works for welding, grinding, foundry work, and other high-heat applications

How to Choose the Right Welding Blanket

Not all heavy duty welding blankets are equal. Consider these factors:

- Temperature Rating:Match it to your welding process (MIG/TIG welding needs higher ratings than soldering)

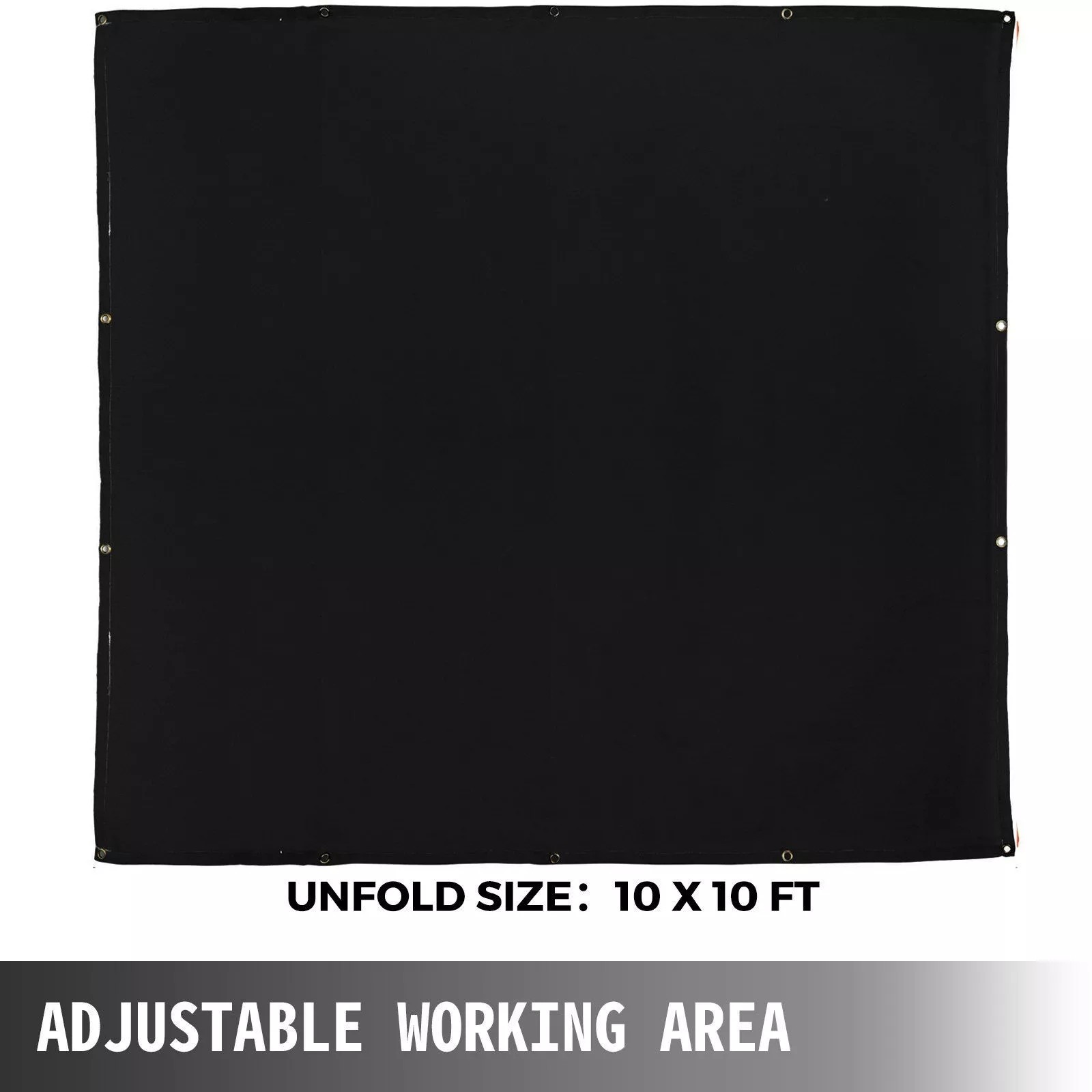

- Size:Measure your work area - common sizes range from 4'x6' to 10'x12'

- Material:Fiberglass is most common; silica offers higher heat resistance

- Thickness:Thicker blankets (1/4"+) last longer in industrial settings

Proper Use and Maintenance Tips

To get the most from your heavy duty welding blanket:

- Always overlap multiple blankets by at least 6 inches when covering large areas

- Secure edges with welding blanket pins or heavy objects

- Inspect regularly for holes or thin spots

- Clean by shaking off debris - never wash fiberglass blankets

- Store flat or rolled (not folded) to prevent crease damage

Common Applications Beyond Welding

Your heavy duty welding blanket has multiple uses:

- Protecting wood floors during fireplace renovations

- Insulating pipes in industrial settings

- Creating safe zones for hot work in confined spaces

- Emergency fire containment in workshops

Safety Considerations

While heavy duty welding blankets reduce risks, remember:

- They're not fireproof - prolonged direct flame contact will damage them

- Always wear proper PPE (gloves, apron, face shield) when welding

- Replace blankets that show significant wear or carbonization

- Keep a fire extinguisher nearby as secondary protection

Frequently Asked Questions

Q: How long does a heavy duty welding blanket last?A: With proper care, 1-3 years in regular use. Industrial settings may require annual replacement.

Q: Can I cut my welding blanket to size?A: Yes, but seal cut edges with high-temperature silicone to prevent unraveling.

Q: Are welding blankets toxic when heated?A: Quality blankets use non-toxic materials, but always work in ventilated areas to avoid inhaling fibers.

Final Recommendations

Invest in a reputable brand heavy duty welding blanket - it's cheaper than repairing fire damage. For most welding shops, a 6'x8' fiberglass blanket with 1,800°F+ rating offers the best balance of protection and value. Remember that proper use is just as important as product quality for effective protection.