Fire Proof Welding Blanket: Essential Safety Gear for Hot Work

This guide explains how fire proof welding blankets protect you from sparks and molten metal. You'll learn their materials, proper use, maintenance, and why they're crucial for welding safety.

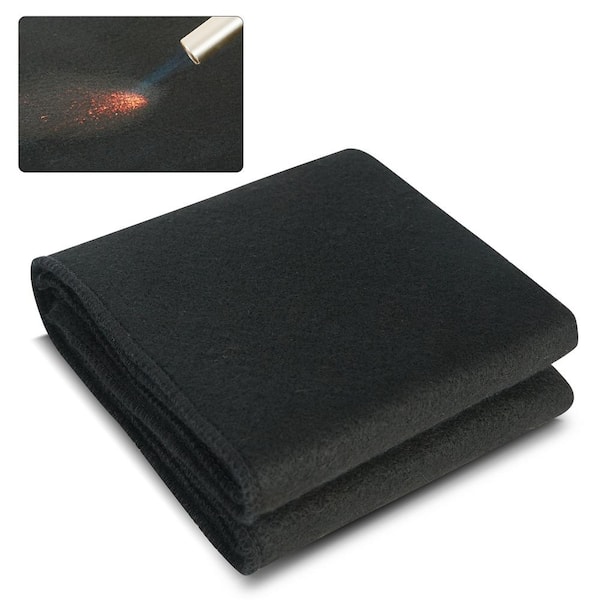

What Is a Fire Proof Welding Blanket?

A fire proof welding blanket is your first line of defense against welding hazards. These specialized covers resist extreme heat, sparks, and molten splatter that occur during welding, cutting, or grinding. Made from flame-resistant materials like fiberglass or silica, they create a protective barrier between your work area and flammable objects.

Key Features of Quality Welding Blankets

When choosing a fire proof welding blanket, look for these essential characteristics:

- Heat resistance:Withstands temperatures up to 1,800°F (982°C)

- Durable construction:Reinforced edges prevent fraying

- Flexibility:Easy to drape over surfaces without cracking

- Lightweight:Simple to move and position as needed

- Non-conductive:Won't transmit electricity during welding

How to Use Your Welding Blanket Safely

Proper placement of your fire proof welding blanket makes all the difference:

- Cover all flammable materials within 35 feet of your work area

- Secure the blanket with weights or clamps to prevent movement

- Overlap multiple blankets by at least 6 inches for complete coverage

- Inspect for damage before each use - replace if holes appear

- Keep a fire extinguisher nearby as additional protection

Maintenance Tips for Longevity

Extend your fire proof welding blanket's lifespan with proper care:

- Shake off debris after each use - never wash with water

- Store flat or rolled in a dry, clean area

- Avoid folding sharply to prevent material fatigue

- Check manufacturer guidelines for specific cleaning methods

- Replace when the material becomes stiff or develops thin spots

Why You Should Never Skip This Safety Step

Many welders underestimate the importance of fire proof welding blankets until it's too late. Consider these facts:

- Welding sparks can travel up to 35 feet and remain hot enough to ignite materials

- Molten metal droplets can burn through regular tarps instantly

- Workshop fires often start from unseen sparks in hidden areas

- Insurance may deny claims if proper safety measures weren't followed

Choosing the Right Blanket for Your Needs

Select your fire proof welding blanket based on these factors:

| Welding Type | Recommended Blanket |

|---|---|

| Light-duty (MIG, TIG) | Fiberglass, 1/16" thickness |

| Heavy-duty (Stick, Plasma) | Silica, 1/8" thickness |

| High-splatter work | Aluminized outer layer |

Common Mistakes to Avoid

Even experienced welders sometimes make these errors with fire proof welding blankets:

- Using damaged blankets with holes or tears

- Placing blankets too close to the actual weld point

- Assuming one blanket covers all scenarios

- Forgetting to protect vertical surfaces

- Using regular tarps as substitutes

Beyond Welding: Other Uses for Fire Blankets

Your fire proof welding blanket has multiple applications:

- Grinding operations

- Hot work in confined spaces

- Emergency fire suppression

- Protecting sensitive equipment near work areas

- Creating temporary heat shields

Investing in a quality fire proof welding blanket protects your workspace, equipment, and most importantly - yourself. Follow these guidelines to maximize safety during all your hot work operations.