Welding Blanket TSC: Ultimate Protection for Hot Work Safety

Summary:Welding blanket TSC provides superior heat and spark protection for welding, cutting, and grinding. This guide explains its features, benefits, and proper usage to enhance workplace safety during hot work operations.

What Is Welding Blanket TSC?

Welding blanket TSC is a specialized safety product designed to protect workers and surrounding areas from sparks, spatter, and heat during welding operations. The "TSC" designation typically refers to its technical specifications - Temperature resistant, Spark-proof, and Chemical-resistant coating.

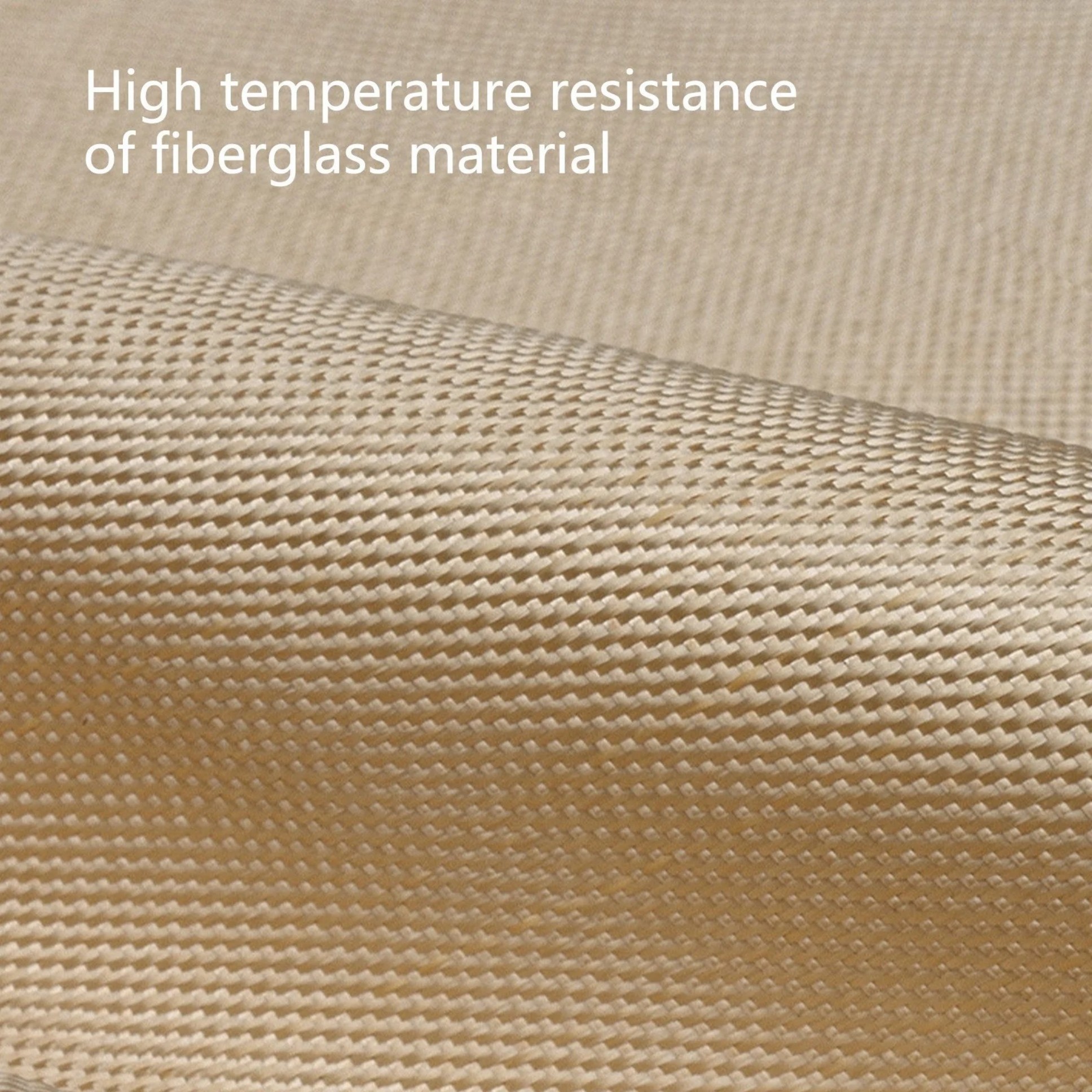

These blankets are made from high-quality materials like fiberglass with silicone coating, offering protection against temperatures up to 2000°F (1093°C). Unlike regular welding blankets, the TSC version provides enhanced durability and longer service life.

Key Features of Welding Blanket TSC

When choosing welding blanket TSC, you should look for these essential features:

- Extreme heat resistance:Withstands temperatures up to 2000°F continuously

- Spark and slag protection:Prevents fire hazards from flying sparks

- Flexible material:Easy to drape over equipment or surfaces

- Chemical resistance:TSC coating repels oils and other workshop chemicals

- Reusable design:Durable enough for repeated use in industrial settings

Benefits of Using Welding Blanket TSC

Investing in welding blanket TSC offers multiple advantages for your workshop:

1. Enhanced safety:Creates a reliable barrier between hot work and flammable materials, reducing fire risks significantly.

2. Cost-effective protection:Prevents damage to expensive equipment and nearby surfaces, saving repair and replacement costs.

3. Versatile applications:Suitable for welding, plasma cutting, grinding, and other high-temperature processes.

4. Compliance with safety standards:Helps meet OSHA and other regulatory requirements for hot work safety.

How to Choose the Right Welding Blanket TSC

Selecting the appropriate welding blanket TSC depends on several factors:

Size considerations:Measure the area you need to protect. Common sizes range from 3'×3' for small jobs to 12'×12' for large projects.

Thickness matters:Thicker blankets (6-8 oz) offer better protection for heavy-duty applications, while thinner ones (4 oz) work for lighter tasks.

Attachment options:Some models include grommets for hanging or fastening, which improves stability during use.

Color coding:Different colors may indicate temperature ratings - check manufacturer specifications.

Proper Use and Maintenance

To maximize the effectiveness and lifespan of your welding blanket TSC:

1. Always inspect for damage before use - replace if there are holes or excessive wear.

2. Position the blanket to cover all vulnerable areas completely, with sufficient overlap.

3. Avoid direct contact with sharp edges that could tear the material.

4. Clean regularly by shaking off debris or using compressed air - avoid harsh chemicals.

5. Store properly when not in use - hang or roll rather than fold to prevent crease damage.

Welding Blanket TSC vs. Alternatives

While other protective solutions exist, welding blanket TSC offers distinct advantages:

Compared to standard welding blankets:TSC versions provide better chemical resistance and longer durability.

Versus fire-resistant tarps:Welding blanket TSC offers superior heat protection specifically designed for welding applications.

Against metal shields:More flexible and easier to position around complex shapes.

Industry Applications

Welding blanket TSC finds use in various sectors:

Construction:Protecting structural elements during welding on job sites.

Manufacturing:Safeguarding production equipment and facilities.

Automotive:Vehicle repair and customization shops.

Shipbuilding:Containing sparks in confined shipyard environments.

Oil and gas:Protecting sensitive equipment during pipeline work.

Safety Tips When Using Welding Blanket TSC

For optimal protection:

- Always wear appropriate PPE in addition to using the blanket

- Keep a fire extinguisher nearby when performing hot work

- Never leave hot welding blanket TSC unattended until completely cooled

- Train all workers on proper deployment techniques

- Follow manufacturer's guidelines for maximum temperature exposure times

Welding blanket TSC is an essential safety tool that provides reliable protection for various hot work applications. By understanding its features, proper usage, and maintenance requirements, you can significantly improve workplace safety while extending the life of your equipment and facilities.