Lightweight Welding Blankets: Essential Protection for Safe Welding

Summary:Lightweight welding blankets protect against sparks, heat, and molten metal during welding. They're flexible, durable, and essential for workplace safety. This guide explains their benefits, materials, and proper usage.

Why You Need a Lightweight Welding Blanket

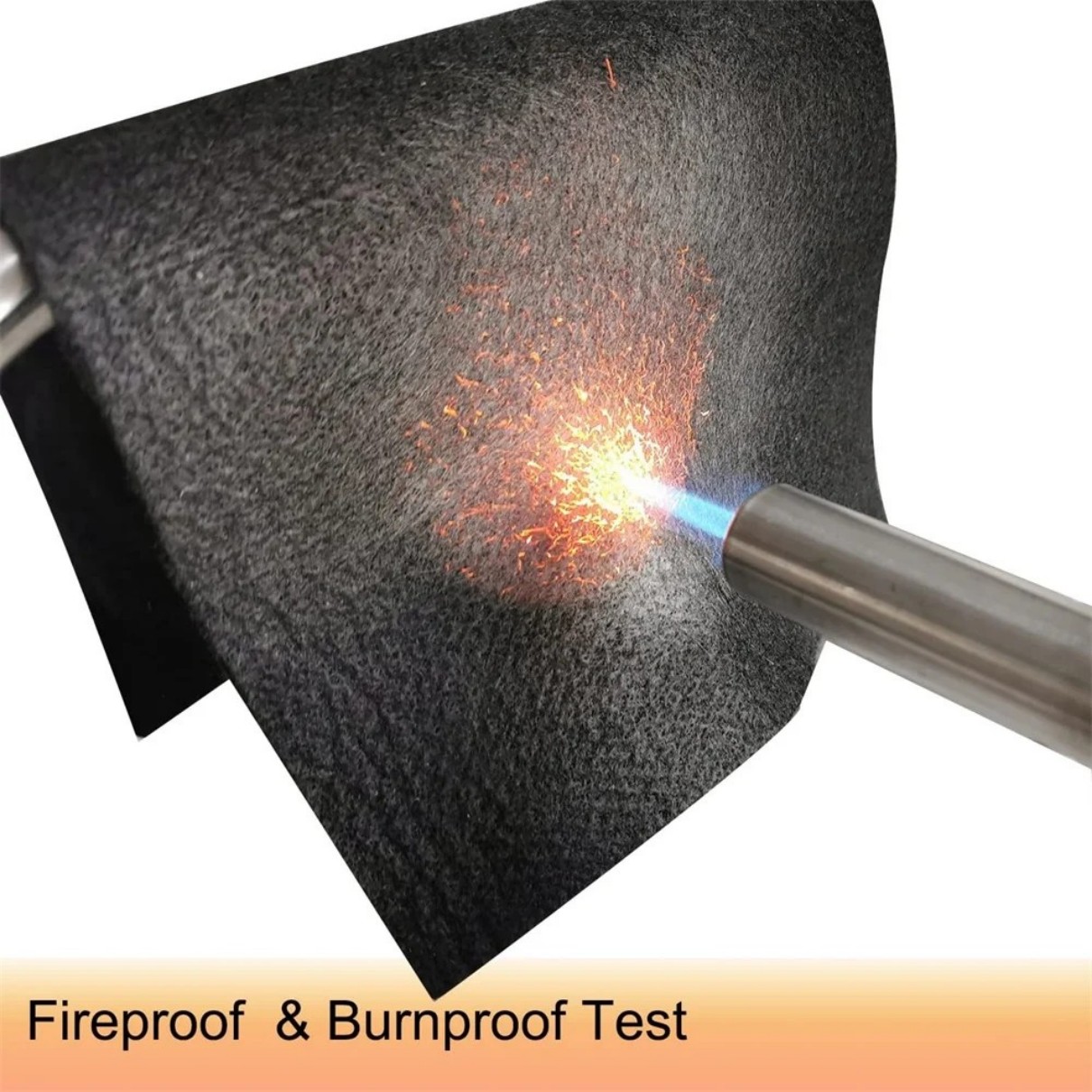

When you're welding, sparks and molten metal can travel several feet, creating fire hazards. A lightweight welding blanketacts as a protective barrier that's easy to handle yet tough enough to withstand 2000°F temperatures. Unlike heavier alternatives, these blankets won't tire you out during setup or storage.

Key Benefits of Lightweight Welding Blankets

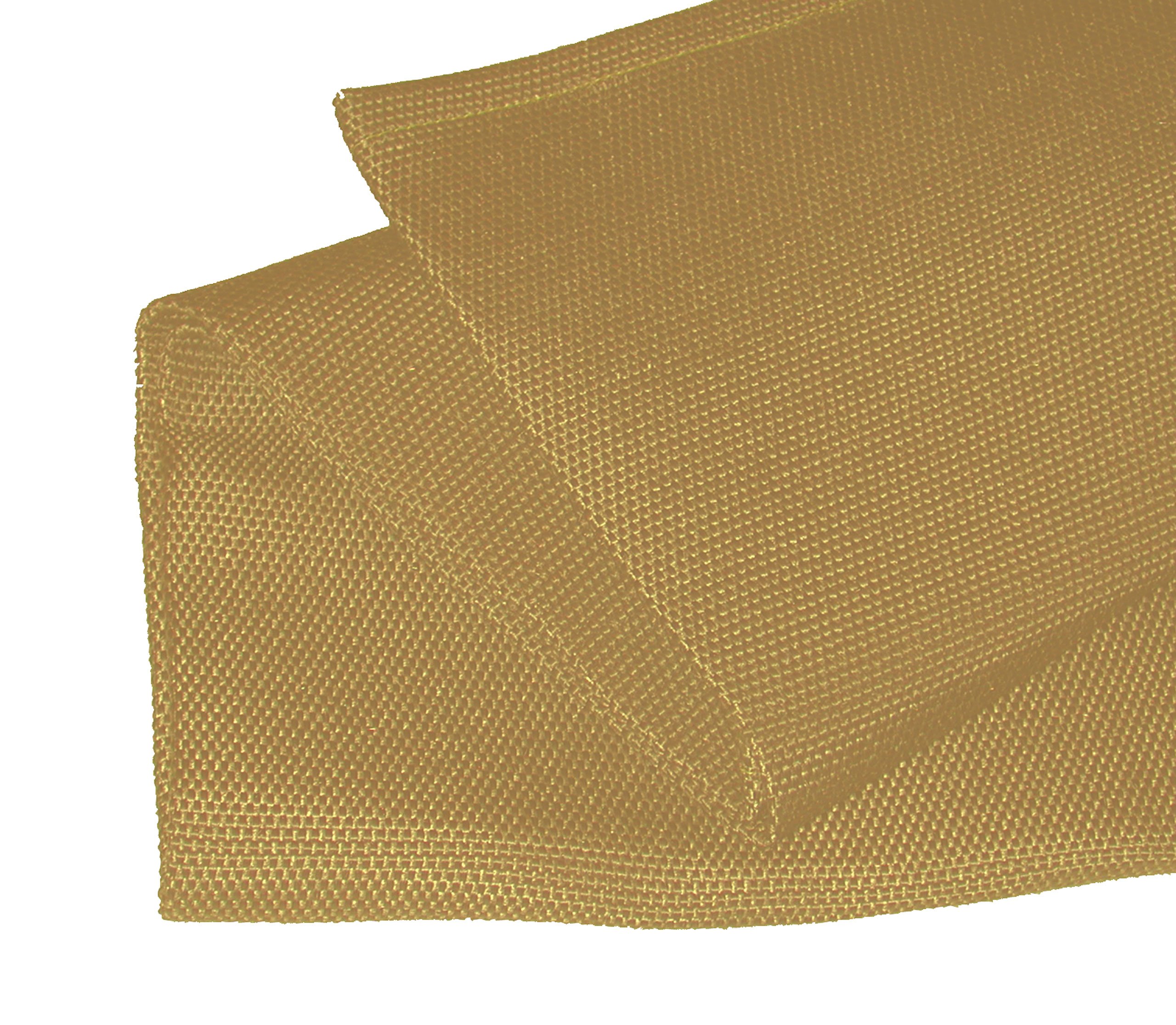

1. Heat Resistance:Made from fiberglass or silica fabrics, they protect against extreme temperatures without adding bulk.

2. Flexibility:Their thin profile (typically 1/16" to 1/8" thick) lets you drape them over irregular surfaces easily.

3. Portability:Weighing 30-50% less than standard blankets, they're ideal for mobile welders or confined spaces.

4. Multi-Purpose Use:Beyond welding, they work for grinding, furnace maintenance, and fireproofing.

Material Comparison

Fiberglass:The most common choice - affordable, resists temperatures up to 1000°F (538°C), and comes in multiple layers.

Silica:Handles up to 2000°F (1093°C) with better flexibility, but costs 20-30% more than fiberglass.

Vermiculite-Coated:Provides extra spark resistance for aluminum or magnesium welding.

How to Choose the Right Blanket

Consider these factors when selecting your lightweight welding blanket:

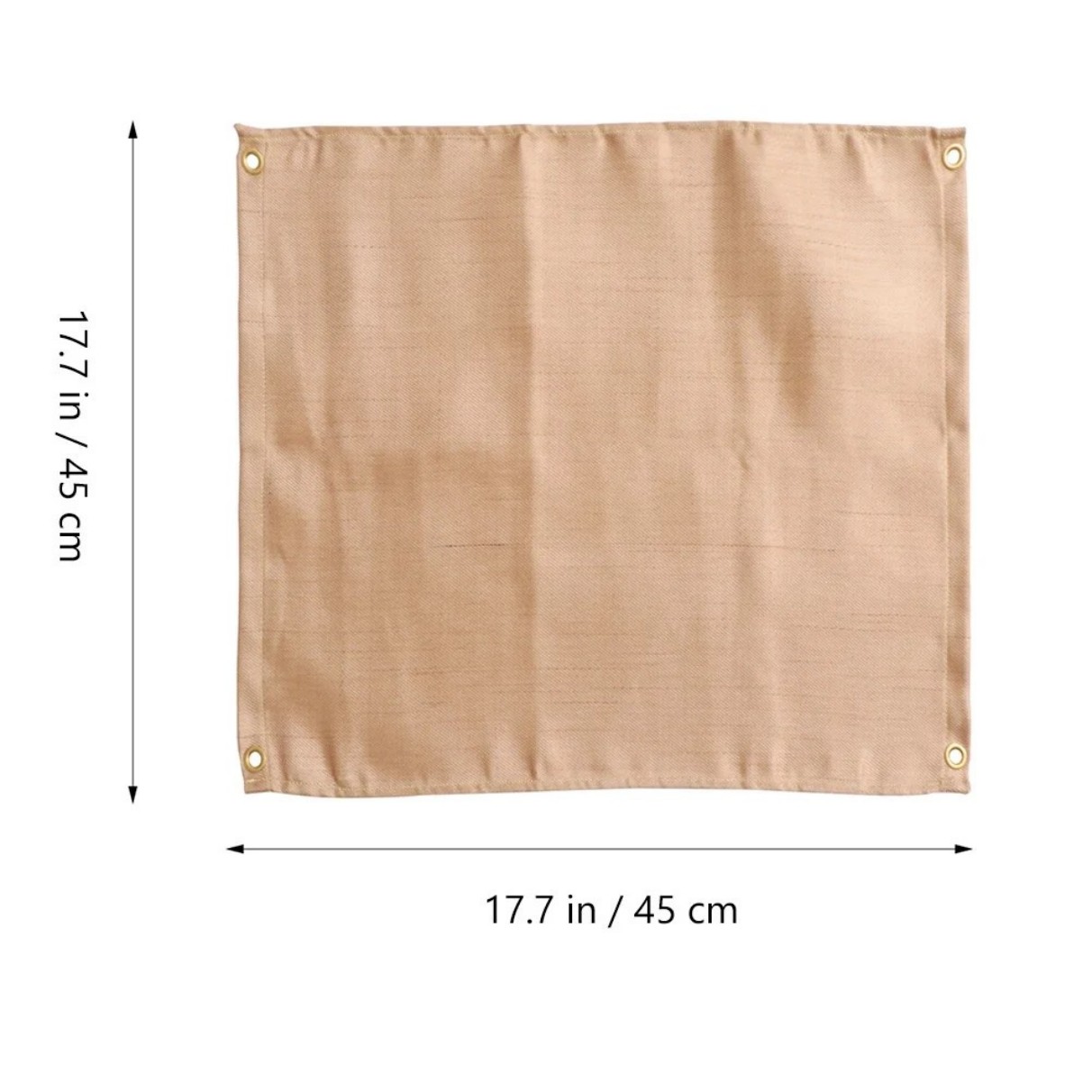

- Size:Standard sizes range from 3'x3' to 12'x12'. Measure your work area plus 2-3 feet of buffer space.

- Temperature Rating:Match it to your welding process (MIG/TIG typically needs higher ratings than stick welding).

- Attachment Options:Look for grommets or hooks if you need to secure the blanket vertically.

Proper Usage and Maintenance

1. Always overlap multiple blankets by at least 6 inches when covering large areas.

2. Inspect for damage before each use - replace if you see holes larger than 1/4 inch.

3. Clean with compressed air or a soft brush; never use water which can degrade the fibers.

4. Store rolled rather than folded to prevent crease damage.

Safety First: Limitations to Remember

While lightweight welding blanketsoffer excellent protection, they're not indestructible:

- Never use them as personal protective equipment (PPE) - always wear proper welding gear.

- Avoid direct contact with the welding arc which can burn through any blanket.

- Replace blankets that become stiff or brittle - this indicates heat damage.

Cost vs. Value

A quality lightweight welding blanketcosts $50-$300 depending on size and material. While cheaper than replacing burned equipment or dealing with fire damage, invest in reputable brands that meet OSHA and ANSI standards.

Where to Use Them

Beyond welding shops, these blankets protect:

- Automotive repair bays

- Shipbuilding dry docks

- Pipeline construction sites

- DIY home workshops

For maximum safety, combine your lightweight welding blanketwith other precautions like fire extinguishers and proper ventilation. When chosen and used correctly, they're one of the most cost-effective ways to prevent workplace accidents.