Post Weld Heat Treatment Blankets: Essential Tools for Metal Fabrication

Post weld heat treatment (PWHT) blankets are specialized heating devices used to control cooling rates and relieve stresses in welded components. This article explains their working principles, applications, and benefits in industrial settings.

What Are Post Weld Heat Treatment Blankets?

Post weld heat treatment blankets are flexible heating systems designed specifically for thermal stress relief in welded structures. Unlike conventional ovens or furnaces, these blankets conform directly to the workpiece shape, providing localized and controlled heating.

You'll typically find them constructed with:

- High-temperature resistant outer layers (often fiberglass or ceramic)

- Embedded heating elements (nichrome or Kanthal wires)

- Insulating materials to maintain temperature uniformity

- Integrated thermocouples for precise temperature monitoring

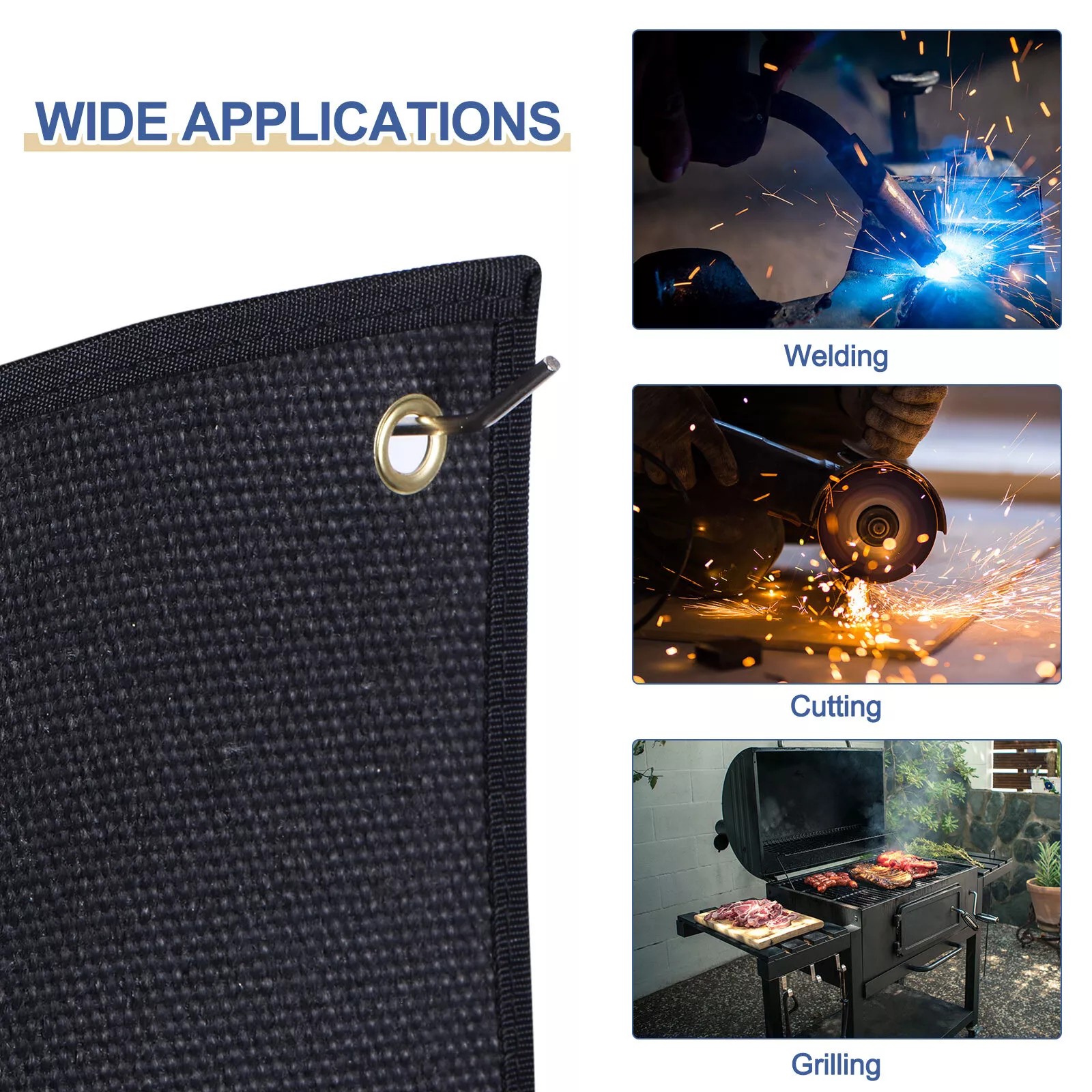

Key Applications of PWHT Blankets

Post weld heat treatment blankets serve critical functions across multiple industries:

- Pressure vessel fabrication:For stress relieving circumferential and longitudinal welds

- Pipeline construction:Used in field welding of high-strength steel pipes

- Shipbuilding:For treating thick plate welds in hull construction

- Power generation:Essential in boiler and turbine component fabrication

- Structural steel:For critical connections in bridges and high-rises

Modern post weld heat treatment blankets can reach temperatures up to 1200°C (2192°F) with temperature uniformity within ±10°C (±18°F), making them suitable for most carbon steel, alloy steel, and stainless steel applications.

Benefits Over Traditional PWHT Methods

Compared to furnace treatments, post weld heat treatment blankets offer distinct advantages:

- Portability:You can use them directly on-site, eliminating the need to move large components

- Energy efficiency:They heat only the required area, reducing energy consumption by 40-60%

- Precision control:Advanced models feature multi-zone temperature control for complex geometries

- Time savings:No cooling/warming cycles for furnaces means faster turnaround times

- Cost-effectiveness:Lower capital investment than building large heat treatment furnaces

Proper Usage of PWHT Blankets

To achieve optimal results with your post weld heat treatment blankets, follow these best practices:

- Clean the weld area thoroughly before blanket installation

- Ensure proper blanket-to-workpiece contact (use ceramic pads if needed)

- Install thermocouples according to code requirements (typically 1 per 4.5m²)

- Program heating/cooling rates according to material specifications

- Monitor temperature uniformity throughout the process

- Follow prescribed holding times based on material thickness

Selecting the Right PWHT Blanket

When choosing post weld heat treatment blankets, consider these factors:

- Temperature range:Match to your material's PWHT requirements

- Size and shape:Ensure coverage of heat affected zone plus margin

- Power requirements:Check available power sources at your site

- Controller capabilities:Look for multi-channel, programmable units

- Durability:Consider abrasion resistance for field use

Safety Considerations

Working with post weld heat treatment blankets requires attention to safety:

- Always inspect blankets for damage before use

- Use appropriate personal protective equipment (heat-resistant gloves, face shields)

- Establish exclusion zones around heated components

- Monitor for potential fire hazards, especially in confined spaces

- Follow lockout/tagout procedures during maintenance

Maintenance and Care

Proper maintenance extends the life of your post weld heat treatment blankets:

- Store rolled or flat in dry conditions

- Clean surfaces regularly to prevent contamination

- Check electrical connections for wear

- Test resistance values periodically

- Replace damaged heating elements promptly

Future Trends in PWHT Blanket Technology

The post weld heat treatment blanket industry continues to evolve with:

- Smart blankets with IoT connectivity for remote monitoring

- Advanced materials offering higher temperature capabilities

- Improved energy efficiency through better insulation designs

- Lightweight options for easier handling

- Integration with automated welding systems

Post weld heat treatment blankets have become indispensable tools in modern metal fabrication. Their flexibility, precision, and cost-effectiveness make them superior to traditional methods for many applications. By understanding their proper use and maintenance, you can significantly improve your welding quality and efficiency.