Chicago Electric Welding Blanket: Safety & Usage Guide for Welders

The Chicago Electric welding blanket protects you from sparks and heat during welding projects. This guide explains its features, proper use, maintenance, and safety benefits to help you work safely and efficiently.

What Is a Chicago Electric Welding Blanket?

A Chicago Electric welding blanket is a protective safety device made from flame-resistant materials. It's designed to shield surfaces and people from welding sparks, molten metal splatter, and radiant heat. These blankets typically consist of fiberglass or other heat-resistant fabrics that can withstand temperatures up to 1,800°F (982°C).

When you're working with a Chicago Electric welder, the welding blanket becomes an essential part of your safety gear. It's different from regular blankets because it won't catch fire or melt when exposed to extreme heat from welding operations.

Key Features of Chicago Electric Welding Blankets

Chicago Electric welding blankets offer several important features:

- High-temperature resistance- Can withstand direct exposure to welding sparks and molten metal

- Durable construction- Made from tightly woven fiberglass or silica fabric

- Flexibility- Can be draped over uneven surfaces or wrapped around objects

- Reusable- Unlike disposable welding curtains, these blankets last through multiple projects

- Portable- Lightweight and easy to store when not in use

How to Use Your Chicago Electric Welding Blanket Properly

To get maximum protection from your Chicago Electric welding blanket, follow these usage tips:

1. Surface Protection:Lay the blanket over any nearby flammable surfaces before starting your weld. This includes wooden floors, workbenches, or any equipment you want to protect.

2. Personal Protection:When working in tight spaces, you can hang the blanket between you and other workers to create a heat barrier. Ensure it's securely fastened and won't fall during work.

3. Equipment Protection:Drape the blanket over nearby gas cylinders or sensitive equipment that might be affected by heat or sparks.

4. Full Coverage:Make sure the blanket extends at least 12 inches beyond your work area to catch any stray sparks or splatter.

Maintenance and Care for Your Welding Blanket

Proper care extends the life of your Chicago Electric welding blanket:

Cleaning:Shake off loose debris after each use. For stubborn residue, gently brush with a soft bristle brush. Never machine wash as this can damage the fibers.

Storage:Fold neatly and store in a dry place away from direct sunlight. Moisture can degrade the material over time.

Inspection:Regularly check for holes, thinning areas, or frayed edges. Replace the blanket if you notice significant wear that compromises protection.

Safety Benefits of Using a Chicago Electric Welding Blanket

Incorporating a Chicago Electric welding blanket into your safety routine provides multiple advantages:

Fire Prevention:The primary benefit is preventing fires caused by sparks landing on flammable materials. Even small sparks can ignite sawdust, paper, or other workshop debris.

Burn Protection:The blanket creates a barrier between hot metal and your skin or clothing, reducing burn risks when handling recently welded pieces.

Work Area Containment:Helps contain your work area, preventing sparks from traveling to unintended locations where they might cause damage or injury.

Regulatory Compliance:Many workplace safety regulations require proper spark containment measures during hot work operations.

Choosing the Right Chicago Electric Welding Blanket

When selecting a welding blanket, consider:

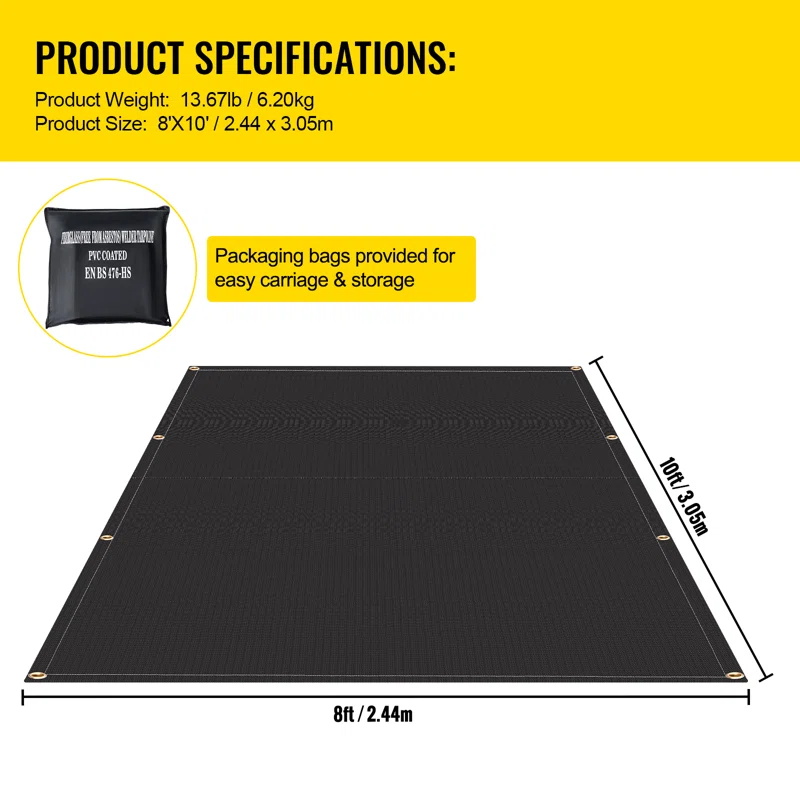

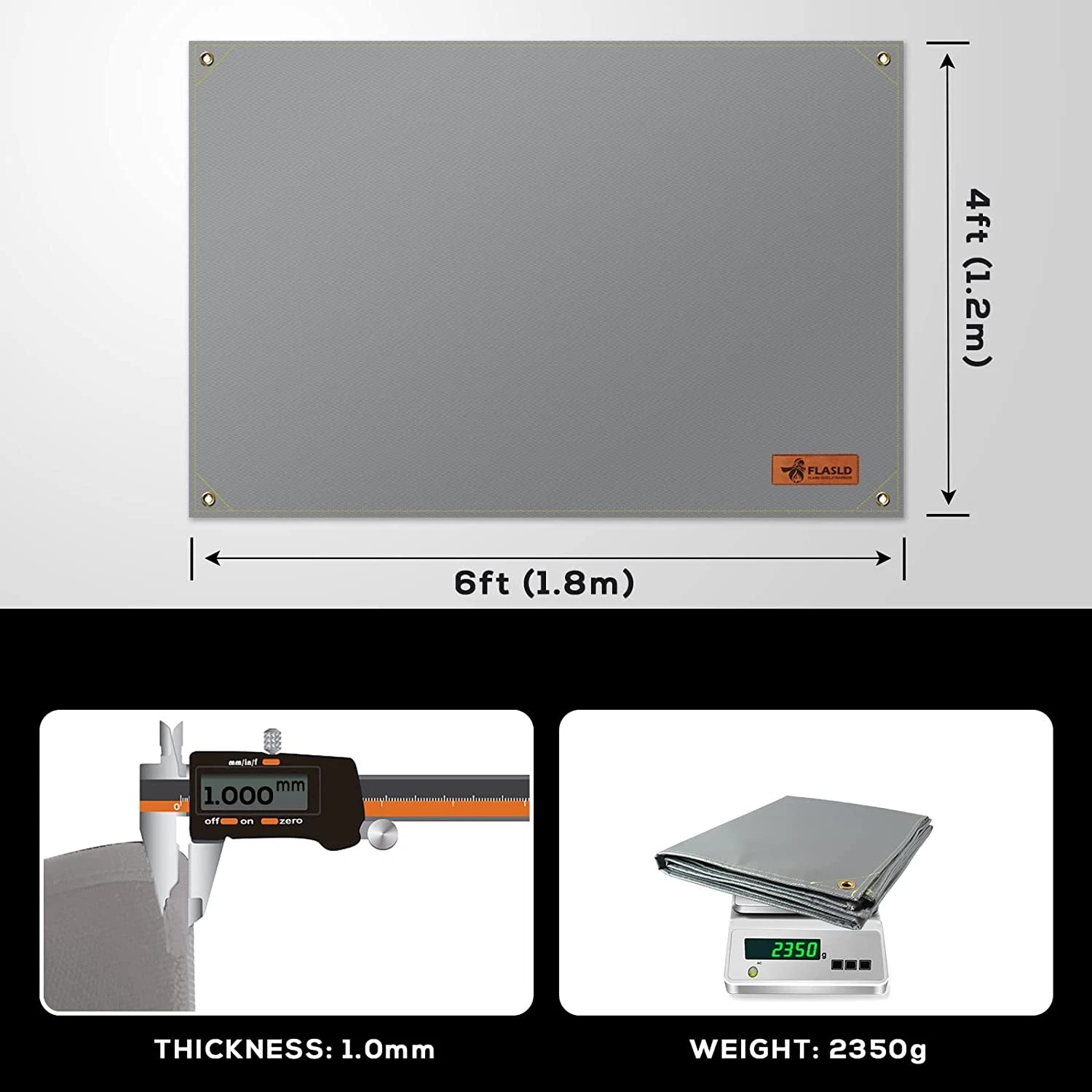

Size:Choose a blanket large enough to cover your typical work area. Chicago Electric offers various sizes to match different project scales.

Temperature Rating:Ensure the blanket's maximum temperature rating exceeds your typical welding temperatures.

Material:Fiberglass is common, but some specialized blankets use silica or other advanced materials for higher heat resistance.

Thickness:Thicker blankets generally offer better protection but may be less flexible.

Common Mistakes to Avoid

Even with a quality Chicago Electric welding blanket, mistakes can reduce its effectiveness:

Insufficient Coverage:Not covering enough area around your work zone leaves surrounding surfaces vulnerable.

Improper Placement:Placing the blanket too close to the weld can lead to burn-through. Maintain adequate distance.

Neglecting Inspection:Using a damaged blanket gives false security. Always inspect before use.

Wrong Material Choice:Using non-welding blankets as substitutes is dangerous and ineffective.

Conclusion

The Chicago Electric welding blanket is an essential safety tool for any welding project. By understanding its proper use, maintenance, and benefits, you can significantly improve your workshop safety. Always prioritize protection when working with high temperatures and molten metal, and your welding blanket will serve as a reliable safety barrier for years to come.