Carbonized Fiber Welding Blanket: Superior Heat Protection for Industrial Use

A carbonized fiber welding blanket provides exceptional heat resistance up to 2000°F, protecting surfaces from sparks, slag, and molten metal during welding operations. Its durable construction makes it ideal for industrial applications.

What Is a Carbonized Fiber Welding Blanket?

A carbonized fiber welding blanket is a specialized protective covering made from heat-resistant materials. Unlike standard welding blankets, it contains carbonized fibers that provide superior thermal insulation and durability. These blankets are designed to withstand extreme temperatures while remaining flexible enough for various applications.

Key Features and Benefits

- Extreme Heat Resistance:Withstands temperatures up to 2000°F (1093°C), making it perfect for high-temperature welding processes

- Durability:Carbonized fibers resist tearing and abrasion, ensuring long service life

- Lightweight:Easy to handle and position despite its robust protection

- Non-Combustible:Won't catch fire or contribute to flame spread

- Versatility:Suitable for MIG, TIG, stick welding, and plasma cutting applications

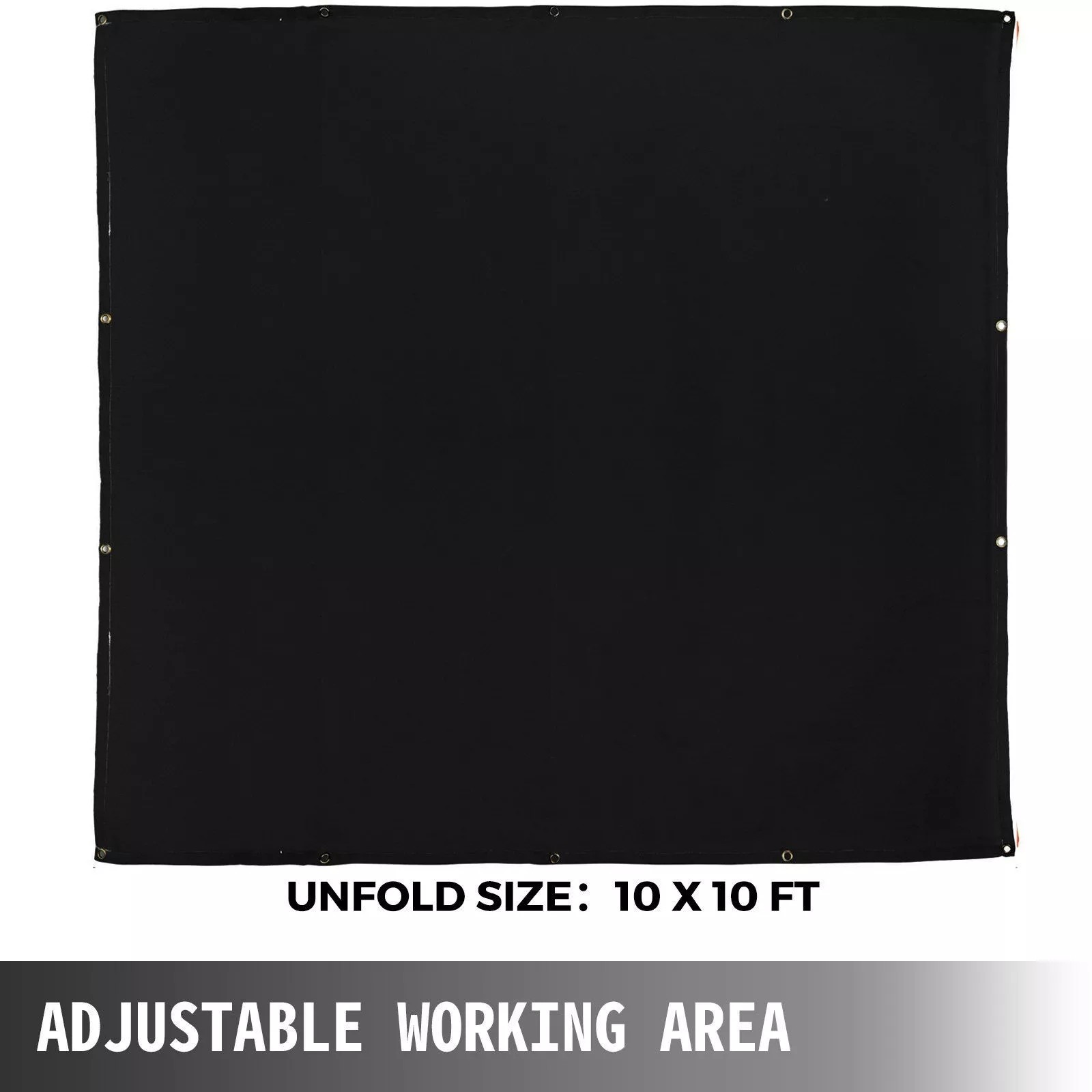

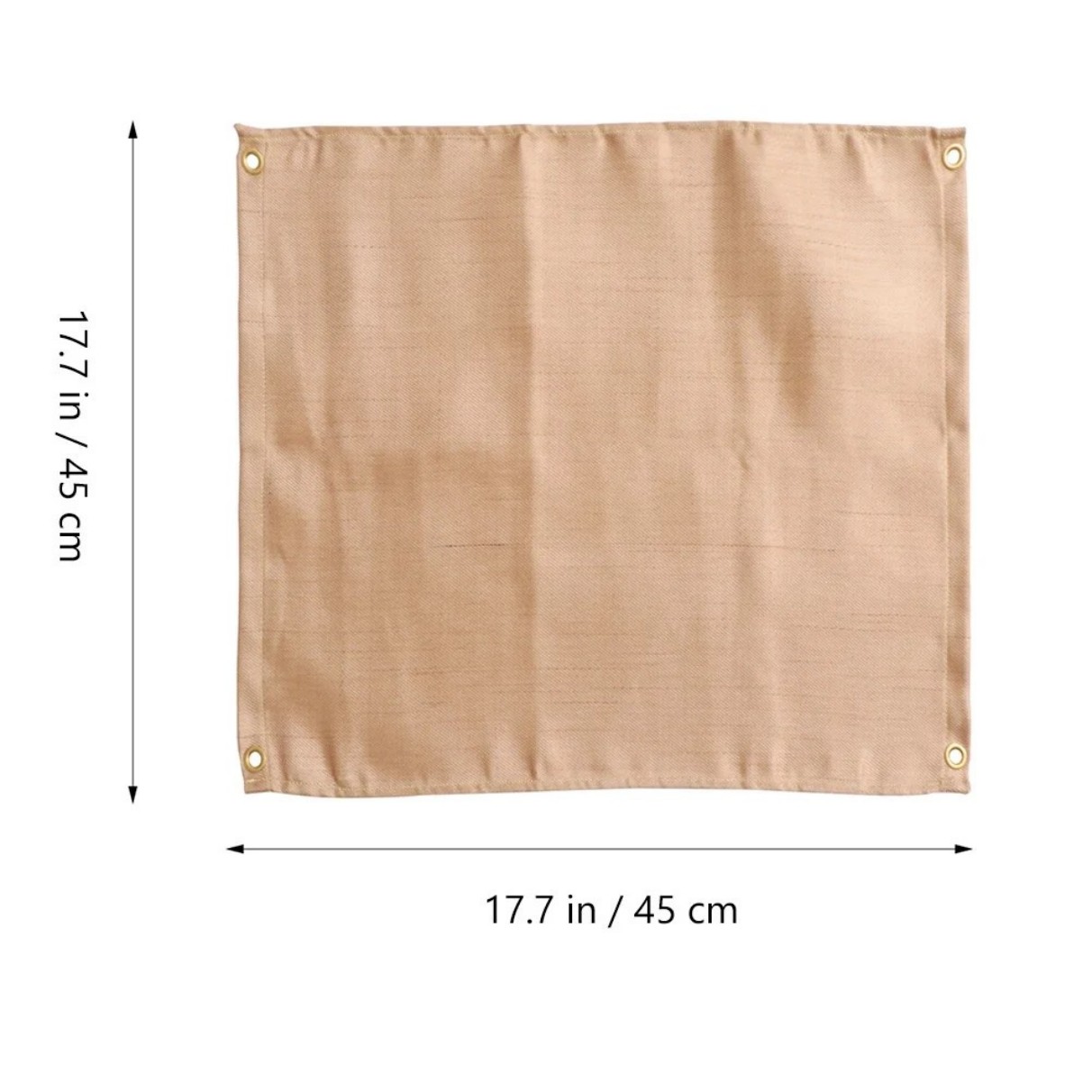

When choosing a carbonized fiber welding blanket, consider thickness (typically 1/8" to 1/4"), size (common options from 3'x3' to 10'x10'), and whether you need treated or untreated fibers for your specific application.

How Carbonized Fiber Differs From Other Materials

Traditional welding blankets often use fiberglass or silica materials. While effective, they can't match the performance of carbonized fiber:

- Carbonized fibers maintain structural integrity at higher temperatures

- They offer better resistance to thermal shock and rapid temperature changes

- The material doesn't degrade as quickly when exposed to molten metal splatter

- Carbonized fiber blankets typically have a longer lifespan than conventional options

Proper Use and Maintenance

To get the most from your carbonized fiber welding blanket:

- Always inspect for damage before use

- Position the blanket to cover all vulnerable areas completely

- Avoid folding or creasing the same spot repeatedly

- Store in a dry location when not in use

- Clean with compressed air or a soft brush - never use water

Applications Beyond Welding

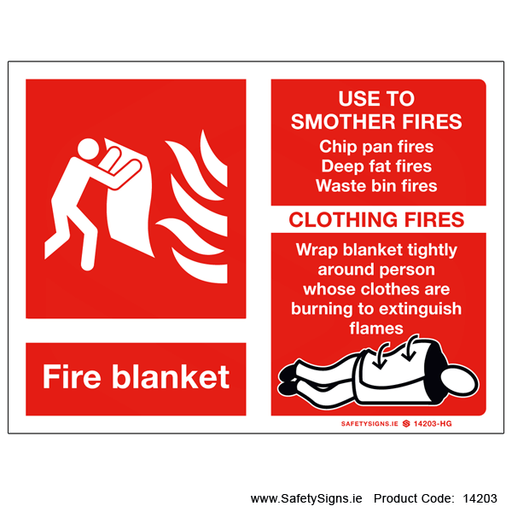

While designed for welding, carbonized fiber blankets have multiple industrial uses:

- Foundry work and metal casting operations

- Fire protection for equipment during hot work

- Thermal insulation in high-temperature manufacturing processes

- Protective covering for sensitive components during heat treatment

Safety Considerations

Even with a carbonized fiber welding blanket, always follow standard welding safety protocols:

- Wear appropriate PPE (gloves, helmet, protective clothing)

- Ensure proper ventilation in the work area

- Keep fire extinguishers readily available

- Never leave hot work unattended

- Allow the blanket to cool completely before handling or storing

Choosing the Right Blanket for Your Needs

Consider these factors when selecting a carbonized fiber welding blanket:

- Temperature rating:Match to your specific welding processes

- Size:Ensure adequate coverage for your work area

- Weight:Heavier blankets offer more protection but may be harder to handle

- Edge treatment:Look for reinforced edges for durability

- Certifications:Check for relevant safety standards compliance

Investing in a quality carbonized fiber welding blanket enhances safety and protects valuable equipment. Its superior heat resistance and durability make it an essential tool for professional welders and industrial operations where high temperatures are routine.