New Welding Blankets: Safety Features and Material Innovations

Summary:Discover how new welding blankets improve workplace safety with advanced materials and smart designs. Learn about heat resistance levels, proper usage, and maintenance for optimal protection.

Why Upgrade to New Welding Blankets?

If you're still using old welding blankets, you're missing out on important safety advancements. New welding blankets offer better protection, durability, and convenience. They're designed to withstand higher temperatures while being lighter and more flexible than older models. The latest materials resist sparks, slag, and molten metal more effectively.

Key Features of Modern Welding Blankets

Today's welding blankets include several improvements:

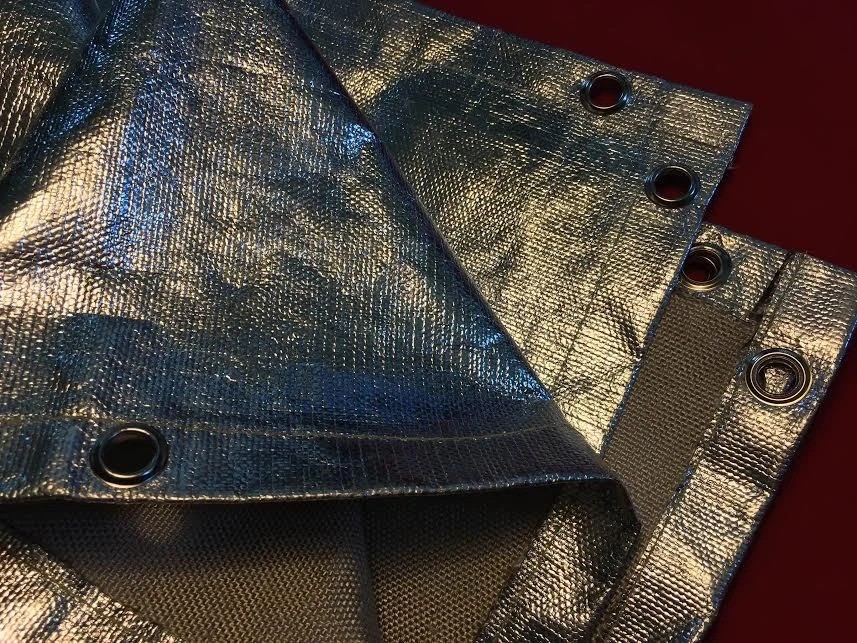

- Multi-layer construction:Combines fiberglass with silicone or ceramic coatings

- Temperature ratings:New models withstand up to 3000°F (1649°C)

- Flexible designs:Easier to drape over complex shapes

- Reinforced edges:Prevents fraying and extends lifespan

- Color-coded systems:Quickly identify heat resistance levels

Choosing the Right Welding Blanket

When selecting new welding blankets, consider these factors:

- Material:Fiberglass remains standard, but ceramic-infused options offer superior protection

- Size:Measure your work area - common sizes range from 4'x6' to 10'x12'

- Thickness:Thicker blankets last longer but may be less flexible

- Certifications:Look for OSHA-compliant and ANSI-rated products

Proper Use and Maintenance

To get the most from your new welding blankets:

- Inspect before each use for holes or thin spots

- Store properly - hang or roll, never fold sharply

- Clean with compressed air or soft brush - never wash with water

- Replace when you notice significant wear or reduced flexibility

Specialized Welding Blanket Options

Manufacturers now offer specialized blankets for different applications:

- Cut-resistant models:For plasma cutting operations

- Welding curtains:Vertical barriers for workstations

- Custom shapes:Pre-formed covers for specific equipment

- Portable kits:Compact sets for mobile welders

Cost vs. Value Considerations

While new welding blankets may cost more initially, they offer better value:

- Longer lifespan reduces replacement frequency

- Better protection lowers accident risks and liability

- Improved ergonomics reduce worker fatigue

- Advanced materials often qualify for safety rebates

Future Trends in Welding Blanket Technology

The next generation of welding blankets may include:

- Smart sensors to monitor blanket condition

- Self-healing materials that repair minor damage

- Eco-friendly, recyclable materials

- Integrated cooling systems for high-heat applications

Upgrading to new welding blankets is one of the simplest ways to improve worksite safety. With better materials and designs, modern options provide superior protection while being easier to use. Always choose blankets rated for your specific welding processes and maintain them properly for maximum safety and value.