Smoker Welding Blanket: Essential Protection for Hot Work Safety

A smoker welding blanket protects surfaces from sparks, slag, and heat during welding, cutting, and grinding. This guide explains its features, benefits, and proper use for maximum safety and efficiency.

What Is a Smoker Welding Blanket?

A smoker welding blanket is a specialized safety tool designed to withstand extreme temperatures from welding, cutting, and other hot work. Unlike regular blankets, it's made from heat-resistant materials like fiberglass or silica fabric that can handle temperatures up to 2000°F (1093°C). The name "smoker" refers to its ability to contain sparks and prevent fire hazards, much like how a smoker contains heat for cooking.

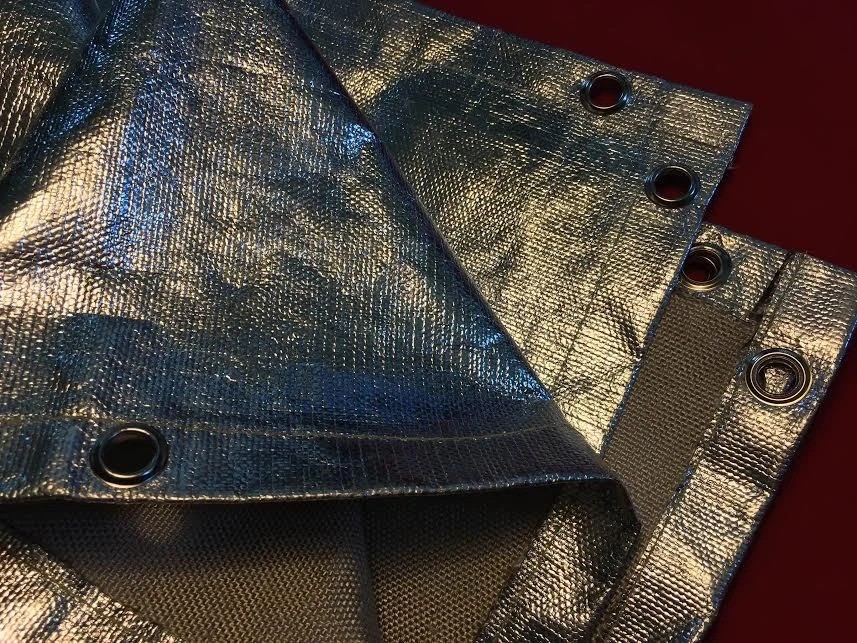

Key Features of Quality Welding Blankets

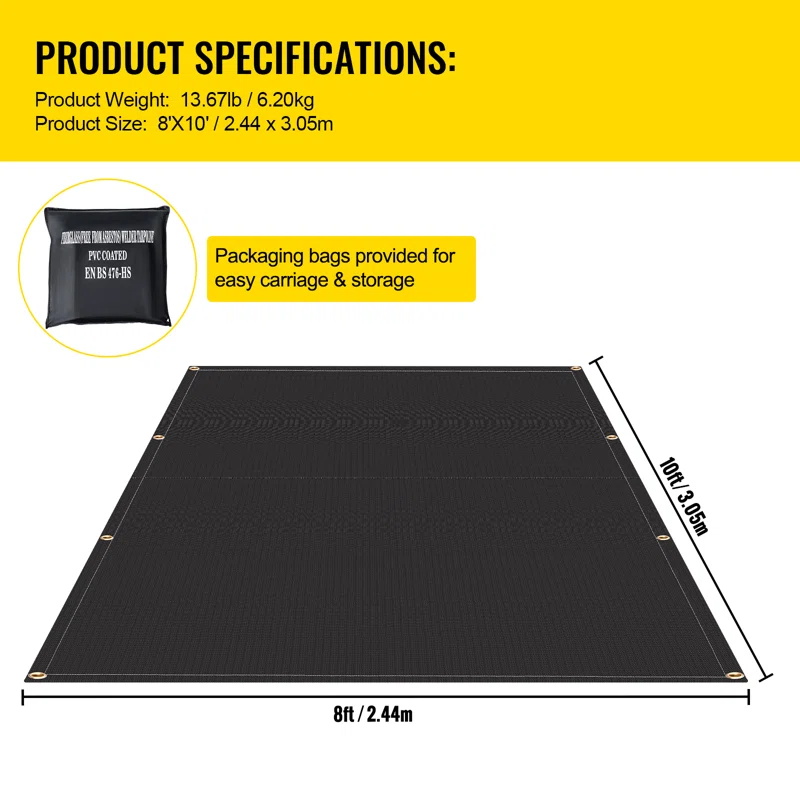

When choosing a smoker welding blanket, look for these essential features:

1. High-temperature resistance- Should withstand at least 1000°F (538°C) continuously

2. Durable construction- Reinforced edges and tear-resistant material

3. Flexibility- Easy to drape over various surfaces and shapes

4. Proper sizing- Common sizes range from 3'x3' to 10'x10' for different applications

5. Chemical resistance- Protection against common workshop chemicals

Why You Need a Smoker Welding Blanket

Every welder should have at least one smoker welding blanket in their toolkit because:

- Prevents fire hazardsby containing sparks and molten metal

- Protects valuable surfaceslike wood floors, countertops, or vehicle interiors

- Improves work safetyby creating designated hot work zones

- Saves cleanup timeby catching debris that would otherwise scatter

- Versatile applicationsbeyond welding - useful for grinding, cutting, and brazing

Proper Use and Maintenance

To get the most from your smoker welding blanket:

1. Inspect before each use- Check for tears or thin spots

2. Position carefully- Cover all nearby flammable surfaces

3. Overlap if needed- Use multiple blankets for larger areas

4. Clean properly- Shake off debris and wipe with damp cloth

5. Store correctly- Fold neatly in a dry place away from chemicals

Choosing the Right Blanket for Your Needs

Consider these factors when selecting a smoker welding blanket:

- Work environment: Indoor shops need different protection than outdoor job sites

- Types of welding: MIG, TIG, and stick welding produce different spark patterns

- Surface sensitivity: Delicate surfaces need thicker, more insulating blankets

- Frequency of use: Professional welders need more durable options than occasional users

Safety Precautions

While smoker welding blankets significantly improve safety, remember:

- They're not fireproof - just fire-resistant for limited time

- Never leave hot blankets unattended

- Keep fire extinguishers accessible

- Combine with other safety gear like gloves and face shields

- Replace blankets showing significant wear

Advanced Applications

Beyond basic protection, smoker welding blankets can be used for:

- Creating temporary welding curtains

- Insulating heat-sensitive components during repairs

- Protecting workbenches from chemical spills

- Emergency heat shielding in various situations

Investing in a quality smoker welding blanket is one of the smartest safety decisions you can make for your workshop. It protects your workspace, prevents accidents, and gives you peace of mind during hot work operations. Choose the right blanket for your needs, use it properly, and maintain it well for years of reliable service.