Welding Heat Shield Blanket: Protection & Safety Guide for Metalworkers

Summary:Welding heat shield blankets protect surfaces from sparks and heat damage. This guide explains their materials, uses, installation tips, and how to choose the right one for your welding projects.

What Is a Welding Heat Shield Blanket?

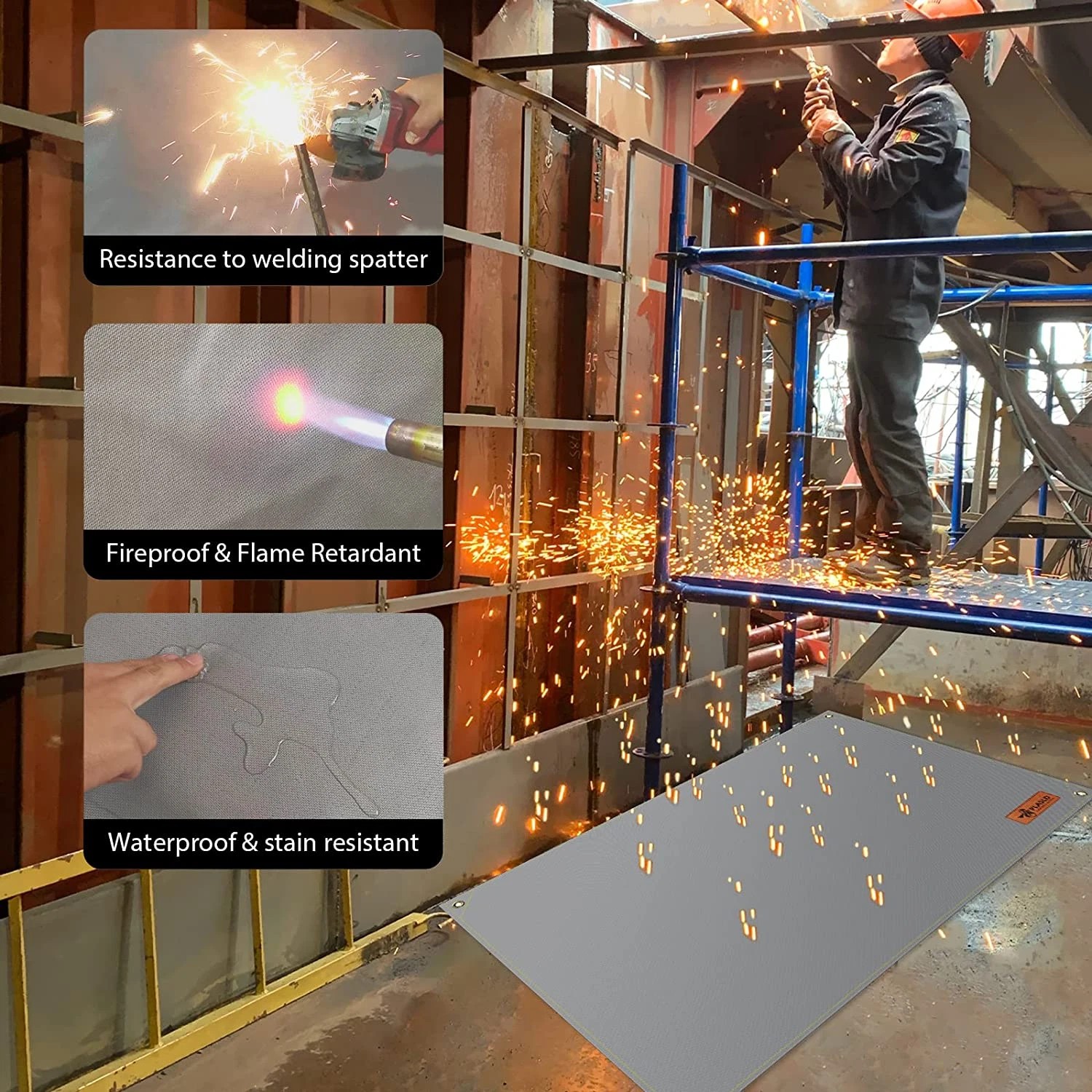

When you're welding, sparks and extreme heat can damage nearby surfaces. A welding heat shield blanket acts as a protective barrier. These flexible, fire-resistant covers shield floors, walls, and equipment from temperatures up to 2,000°F (1,093°C). Unlike rigid shields, they conform to irregular shapes while maintaining safety.

Key Benefits of Using Welding Heat Shield Blankets

You'll appreciate these advantages:

- Prevents fire hazardsby containing sparks and molten metal splatter

- Protects sensitive surfaceslike finished floors or electrical components

- Reusable designsaves money compared to disposable alternatives

- Portable protectionthat's easy to move between job sites

- Versatile applicationsbeyond welding - useful for grinding and cutting too

Materials Matter: Choosing Your Welding Heat Shield Blanket

Not all welding blankets perform equally. Look for these materials:

- Fiberglass with silicone coating- Most common, handles 1,000-1,800°F

- Ceramic fiber- Withstands up to 2,300°F, ideal for high-heat applications

- Carbon fiber- Lightweight yet durable for frequent use

- Vermiculite-coated- Excellent for spark containment in shipyards

Thickness typically ranges from 1/16" to 1/4". Thicker blankets offer better protection but are less flexible.

Proper Installation Techniques

To maximize your welding heat shield blanket's effectiveness:

- Clean the surface before installation to prevent trapped debris

- Overlap multiple blankets by at least 6 inches for complete coverage

- Secure edges with welding blanket pins or high-temperature tape

- Keep at least 12 inches between the blanket and welding area when possible

- Inspect for damage before each use - replace if you see significant wear

Maintenance and Care Tips

Extend your welding heat shield blanket's lifespan with proper care:

- Shake off debris after each use - never wash with water

- Store flat or rolled (not folded) to prevent crease damage

- Keep away from oils and chemicals that degrade materials

- Mark damaged areas with heat-resistant paint for monitoring

- Replace when more than 10% of the surface shows significant wear

Specialized Applications

Beyond standard welding, these blankets excel in:

- Pipeline welding- Protect environmentally sensitive areas

- Aerospace manufacturing- Shield composite materials

- Automotive repair- Prevent damage to vehicle interiors

- Foundry work- Contain molten metal spills

- Shipbuilding- Fire protection in confined spaces

Safety Considerations

While welding heat shield blankets reduce risks, remember:

- They don't replace proper ventilation - welding fumes remain hazardous

- Never use damaged blankets - compromised areas can't protect effectively

- Wear appropriate PPE regardless of blanket use

- Keep fire extinguishers accessible when welding

- Follow all OSHA and local safety regulations

Choosing the Right Size

Measure your work area and add 20% for coverage overlap. Common sizes include:

- 3' x 4' - Small repair jobs

- 6' x 6' - Most workshop needs

- 8' x 10' - Large industrial applications

- Custom sizes - Available for unique project requirements

Cost vs. Quality Balance

Investing in quality welding heat shield blankets pays off:

- Economy models ($50-$100) suit occasional use

- Mid-range ($100-$300) offer better durability for daily use

- Premium blankets ($300+) feature advanced materials for extreme conditions

Consider your usage frequency and temperature requirements when choosing.

Conclusion

A welding heat shield blanket is essential safety equipment that protects your workspace and prevents costly damage. By selecting the right material, size, and quality for your needs, you ensure both safety and efficiency in your welding operations. Proper installation and maintenance will maximize your investment while keeping your work environment secure.