Coated Fiberglass Welding Blankets: Heat Protection Solutions

Summary:Coated fiberglass welding blankets protect against sparks, slag, and heat in welding applications. These durable, heat-resistant covers shield surfaces and workers from welding hazards while being lightweight and flexible.

What Are Coated Fiberglass Welding Blankets?

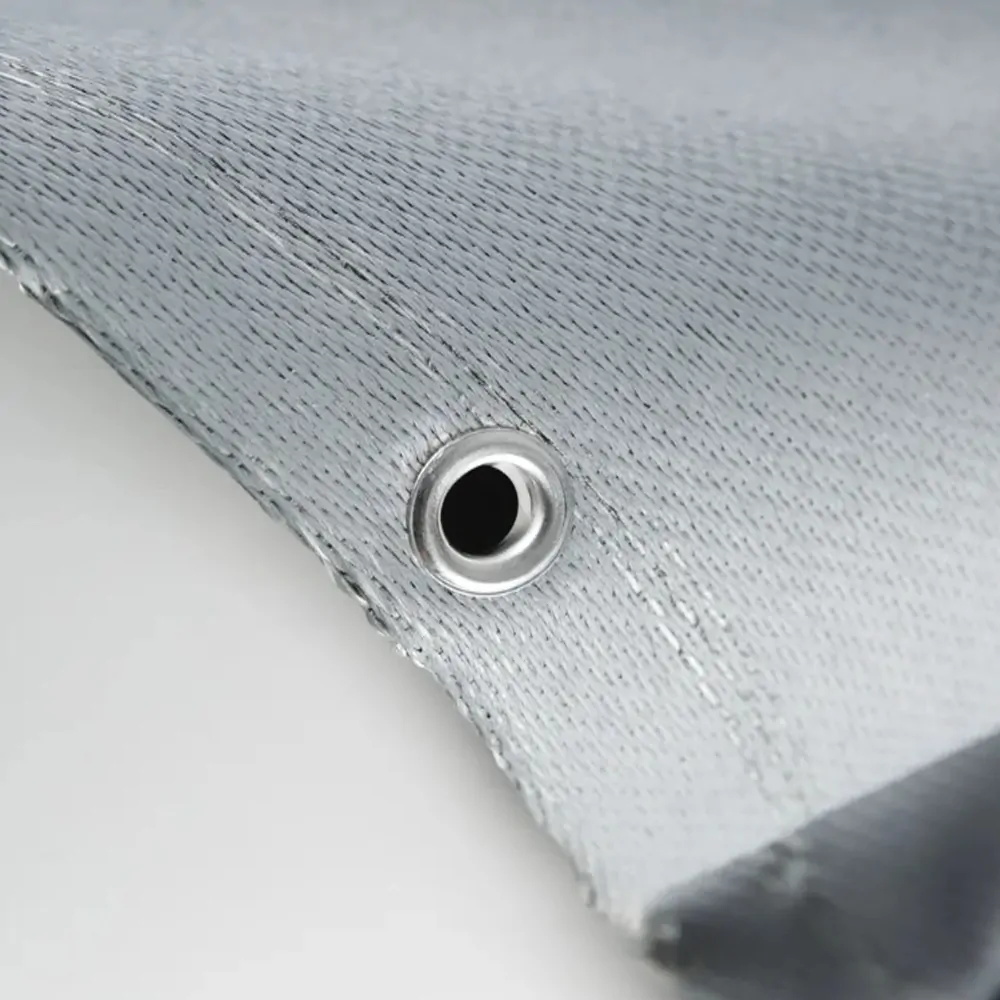

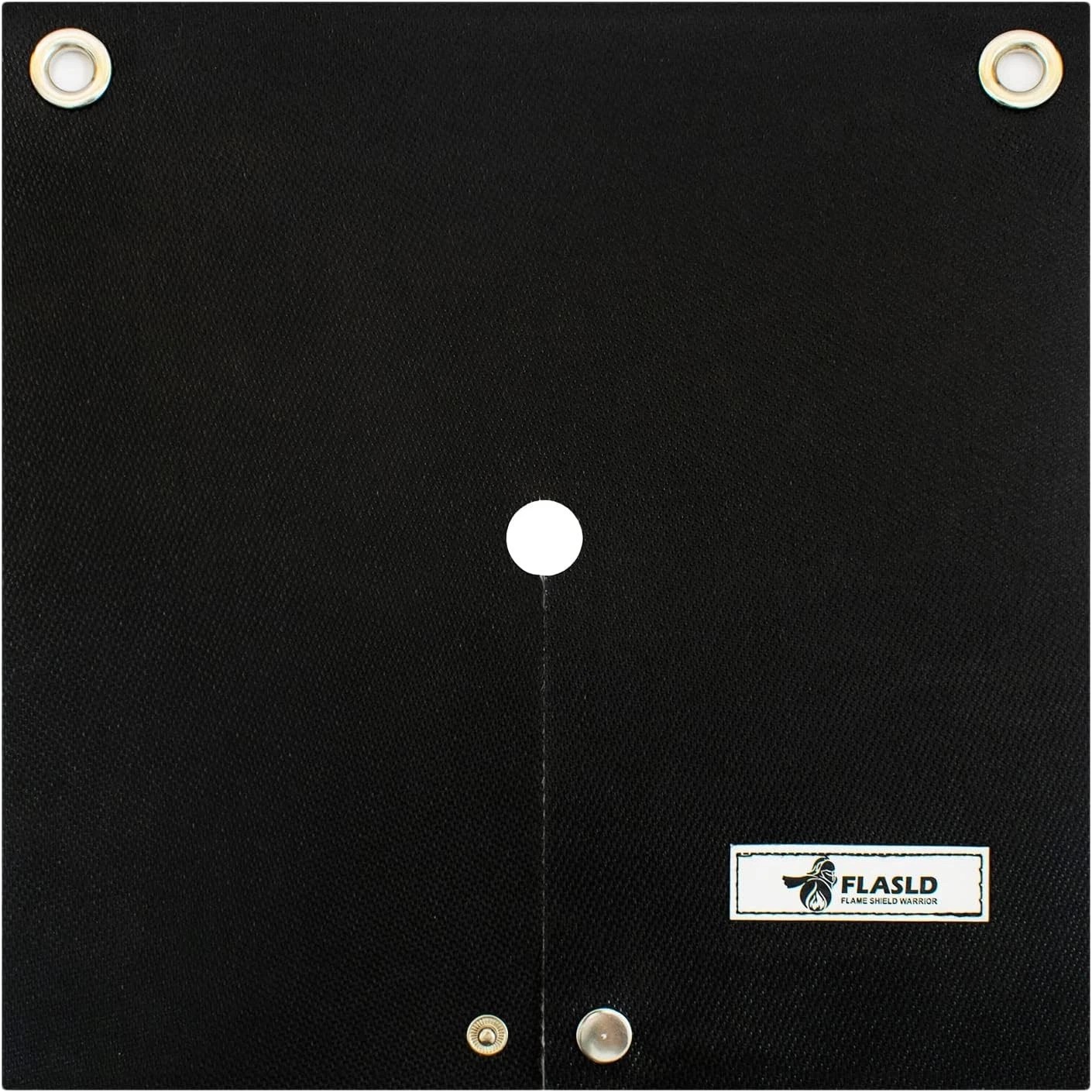

When you're working with welding equipment, you need reliable protection against heat and sparks. Coated fiberglass welding blankets provide exactly that. Made from woven fiberglass with a protective coating (usually silicone or PVC), these blankets withstand temperatures up to 1000°F (538°C) or higher depending on the specific product.

Key Benefits for Your Workspace

Why choose coated fiberglass welding blankets over other options? First, they're incredibly durable - the fiberglass core resists tearing, while the coating adds extra strength. Second, they're flexible enough to drape over uneven surfaces yet rigid enough to stay in place during work. Third, they provide excellent heat insulation while remaining lightweight.

The silicone or PVC coating serves multiple purposes: it reinforces the fiberglass, creates a smoother surface that's easier to clean, and prevents loose fibers from becoming airborne. This makes coated versions safer than uncoated fiberglass blankets in many applications.

Common Applications You Should Know

You'll find coated fiberglass welding blankets useful in various scenarios:

- Protecting floors and walls from welding sparks

- Covering valuable equipment near welding areas

- Creating temporary welding curtains

- Shielding vehicles during auto body repairs

- Industrial furnace maintenance

Choosing the Right Blanket for Your Needs

When selecting a coated fiberglass welding blanket, consider these factors:

- Temperature rating:Match this to your typical welding temperatures

- Coating type:Silicone offers higher heat resistance; PVC is more economical

- Thickness:Thicker blankets (like 1/8") provide more protection

- Size:Measure your work area to ensure proper coverage

- Edge treatment:Look for reinforced edges for longer lifespan

Proper Use and Maintenance Tips

To get the most from your coated fiberglass welding blanket:

- Always inspect for damage before use

- Keep the blanket flat when possible - folding creates weak points

- Clean with compressed air or a soft brush (avoid harsh chemicals)

- Store in a dry place away from direct sunlight

- Replace when the coating shows significant wear or cracking

Safety Considerations

While coated fiberglass welding blankets offer excellent protection, remember they're not fireproof - just fire-resistant. Never leave hot materials on the blanket unattended. Always wear proper PPE when welding, as the blanket is just one layer of protection. Position the blanket so sparks can't travel behind it to flammable materials.

Comparing to Alternative Materials

How does coated fiberglass stack up against other welding protection options? Leather offers durability but is heavier and more expensive. Uncoated fiberglass is cheaper but sheds fibers. Ceramic blankets withstand higher temperatures but are brittle. For most general welding applications, coated fiberglass provides the best balance of protection, durability, and value.

Where to Buy Quality Blankets

Look for reputable welding supply stores or industrial safety suppliers. Many offer different grades - industrial-grade blankets typically last longer than economy versions. Some manufacturers offer custom sizes if standard dimensions don't fit your workspace. Always check product certifications to ensure quality and safety standards.

By understanding these aspects of coated fiberglass welding blankets, you can make informed decisions to protect your work area effectively. These versatile safety tools deserve a place in any welding environment where heat and spark protection matters.