Welding Blanket Guide - Safety, Uses, and Best Practices

A welding blanket protects against sparks, heat, and molten metal during welding. This guide explains how to choose, use, and maintain welding blankets for optimal safety and performance in various applications.

What is a Welding Blanket?

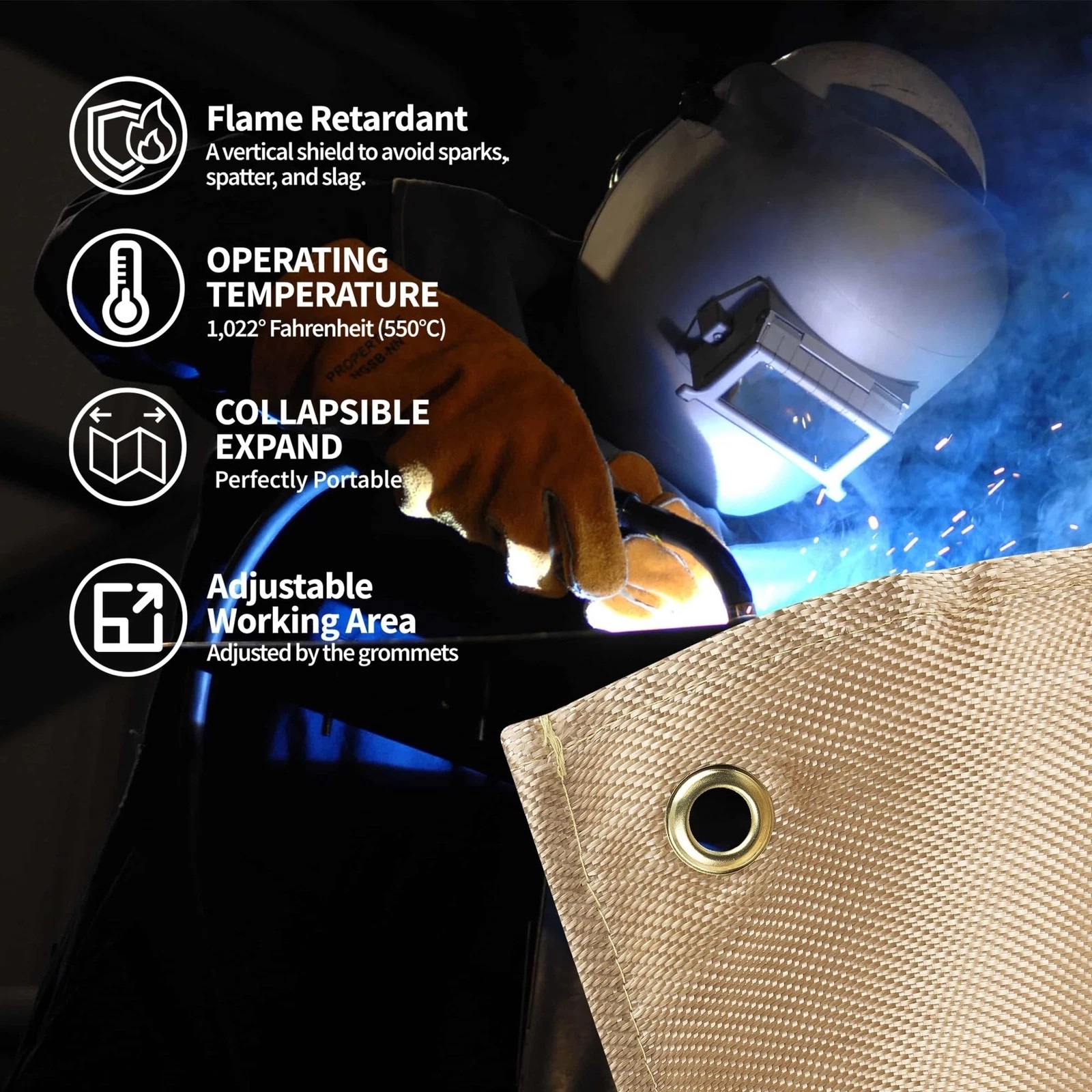

A welding blanket is a heat-resistant protective covering made from materials like fiberglass, silica, or ceramic fibers. You use it to shield surrounding areas from welding sparks, slag, and radiant heat. These blankets come in different sizes, thicknesses, and temperature ratings to match your specific welding needs.

Key Benefits of Using a Welding Blanket

- Fire prevention:Stops sparks from igniting flammable materials nearby

- Heat protection:Shields surfaces from radiant heat damage

- Spatter control:Contains molten metal droplets

- Work area protection:Keeps your workspace clean and safe

- Versatility:Useful for welding, grinding, and other hot work

Always inspect your welding blanket before use. Look for holes, tears, or thin spots that could compromise protection. Damaged blankets should be replaced immediately.

Types of Welding Blankets

Choose the right welding blanket based on your work requirements:

Fiberglass Welding Blankets

These are the most common and affordable options. They typically withstand temperatures up to 1,000°F (538°C) and work well for light to medium welding tasks. You'll find them useful for MIG and stick welding applications.

Silica Welding Blankets

With higher temperature resistance (up to 1,800°F/982°C), silica blankets offer better protection for heavy-duty welding. They're more flexible than fiberglass and resist abrasion better, making them ideal for professional workshops.

Ceramic Welding Blankets

These provide the highest protection, handling temperatures up to 2,300°F (1,260°C). Use ceramic blankets for high-heat applications like plasma cutting or when working with exotic metals. They're more expensive but last longer under extreme conditions.

How to Use a Welding Blanket Properly

- Cover all flammable surfaces within 35 feet of your work area

- Overlap multiple blankets by at least 6 inches if covering large areas

- Secure the blanket with weights or clamps to prevent movement

- Position the blanket to protect from both sparks and radiant heat

- Keep the blanket clean and free from oil or grease buildup

Maintenance and Care Tips

Proper care extends your welding blanket's lifespan:

- Shake out debris after each use

- Store folded or rolled in a dry location

- Clean with compressed air or a soft brush - avoid water

- Never use detergent or chemicals that could degrade the material

- Rotate blankets periodically to distribute wear evenly

Choosing the Right Welding Blanket

Consider these factors when selecting a welding blanket:

- Temperature rating:Must exceed your maximum working temperature

- Size:Should cover all vulnerable areas with some overlap

- Thickness:Thicker blankets offer better protection but are less flexible

- Material:Match to your specific welding process

- Certifications:Look for OSHA or ANSI compliance

Common Applications Beyond Welding

While designed for welding, these blankets have multiple uses:

- Protecting surfaces during grinding or cutting operations

- Insulating pipes or equipment during maintenance

- Creating temporary heat shields in automotive work

- Fireproofing areas during hot work permits

- Emergency fire containment (as secondary protection)

Never use a welding blanket as primary fire protection. They're designed to contain sparks and moderate heat, not stop active flames. Always keep proper fire extinguishers nearby.

Safety Precautions

Follow these safety guidelines when using welding blankets:

- Wear appropriate PPE (gloves, goggles) when handling hot blankets

- Allow blankets to cool completely before moving or storing

- Never use damaged or degraded blankets

- Keep blankets away from open flames unless specifically rated for such use

- Train all workers on proper blanket usage and limitations

Conclusion

A quality welding blanket is essential safety equipment for any welding operation. By choosing the right type, using it properly, and maintaining it well, you'll protect both your work area and yourself from welding hazards. Remember that no blanket replaces proper safety procedures - always combine blanket use with other protective measures for complete safety.