Industrial Fire Blanket Roll: Essential Safety Gear for Workplace Protection

Industrial fire blanket rolls are critical safety tools that smother small fires by cutting off oxygen. This guide explains their features, proper usage, and why they're indispensable in industrial settings for protecting workers and equipment.

What Is an Industrial Fire Blanket Roll?

An industrial fire blanket roll is a specially designed fire suppression tool made from flame-resistant materials like fiberglass or wool. Unlike standard fire blankets, these come in roll form for easier storage and deployment in large industrial spaces.

Key characteristics include:

- High-temperature resistance (typically up to 1000°F/538°C)

- Flexible, rollable design for compact storage

- Larger sizes (often 6'×8' or bigger) for industrial applications

- Durable construction to withstand harsh environments

How Industrial Fire Blanket Rolls Work

When you unroll and place an industrial fire blanket over flames, it starves the fire of oxygen - one of the three elements needed for combustion (along with heat and fuel). The blanket's tight weave prevents air from feeding the flames while containing heat and sparks.

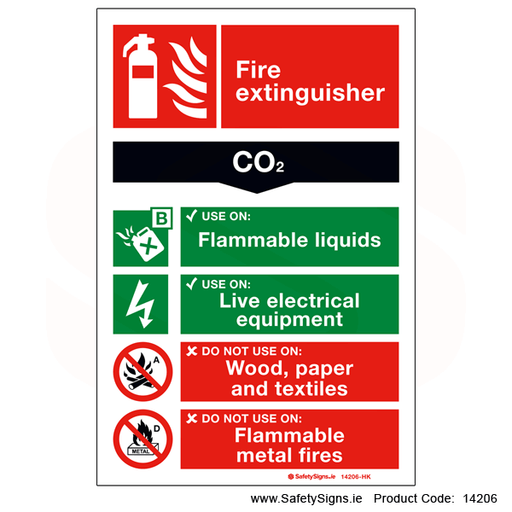

These blankets are particularly effective on:

- Small liquid fires (oil, grease, solvents)

- Electrical equipment fires

- Clothing fires on personnel

- Containing sparks during hot work operations

Key Applications in Industrial Settings

Industrial fire blanket rolls serve multiple protective functions:

1. Machine Protection:Keep rolls near CNC machines, presses, or any equipment with fire risks. The roll format lets you quickly cover larger machinery.

2. Welding Areas:Hang rolls near welding stations to smutter sparks or cover flammable materials. Their flexibility allows wrapping around irregular shapes.

3. Chemical Storage:Store with chemical cabinets to contain potential solvent fires. The non-reactive materials won't interact with most chemicals.

4. Emergency Stations:Mount in clearly marked locations throughout facilities for rapid access during emergencies.

Choosing the Right Industrial Fire Blanket Roll

Selecting the appropriate blanket involves considering:

- Size:Measure your highest-risk areas - larger spaces need bigger blankets (minimum 6'×8' for industrial use)

- Material:Fiberglass offers excellent heat resistance; wool provides better flexibility

- Certifications:Look for NFPA 701, EN 1869, or other relevant safety standards

- Deployment Method:Some rolls come with quick-release containers for faster access

Proper Usage Techniques

To effectively use an industrial fire blanket roll:

- Pull the blanket from its container using the corner tabs (never the middle)

- Hold the blanket as a shield between you and the fire as you approach

- Gently place (don't throw) the blanket over the flames

- Leave the blanket in place until the area completely cools (minimum 30 minutes)

- Never reuse a deployed blanket - replace immediately after use

Maintenance and Inspection

Regular checks ensure your industrial fire blanket roll remains effective:

- Inspect monthly for tears, discoloration, or contamination

- Ensure the storage container is clean and unobstructed

- Replace every 5-7 years (or immediately after use)

- Train staff on location and proper usage during safety drills

Advantages Over Other Fire Suppression Methods

Industrial fire blanket rolls offer unique benefits:

- No cleanup:Unlike extinguishers, they leave no chemical residue

- Versatility:Effective on multiple fire types without specialized agents

- Safety:No risk of spreading fires like water might

- Ease of use:Requires minimal training compared to extinguishers

Common Mistakes to Avoid

Maximize your industrial fire blanket roll's effectiveness by avoiding these errors:

- Storing near heat sources that could damage the material

- Using on large or spreading fires (blankets are for small, contained fires only)

- Attempting to smother gas fires (shut off gas supply first)

- Placing blankets over victims still standing (this can trap heat)

Industrial fire blanket rolls are simple yet powerful tools that belong in every facility's safety program. Their roll format provides practical advantages for industrial environments where rapid deployment and large coverage areas matter most.