Fire Blanket for Insulation: A Comprehensive Guide to Safe and Efficient Thermal Protection

Fire blankets provide excellent insulation against heat and flames. This guide explains how they work, their thermal properties, proper usage, and key benefits for both emergency protection and industrial applications.

What Makes Fire Blankets Effective for Insulation?

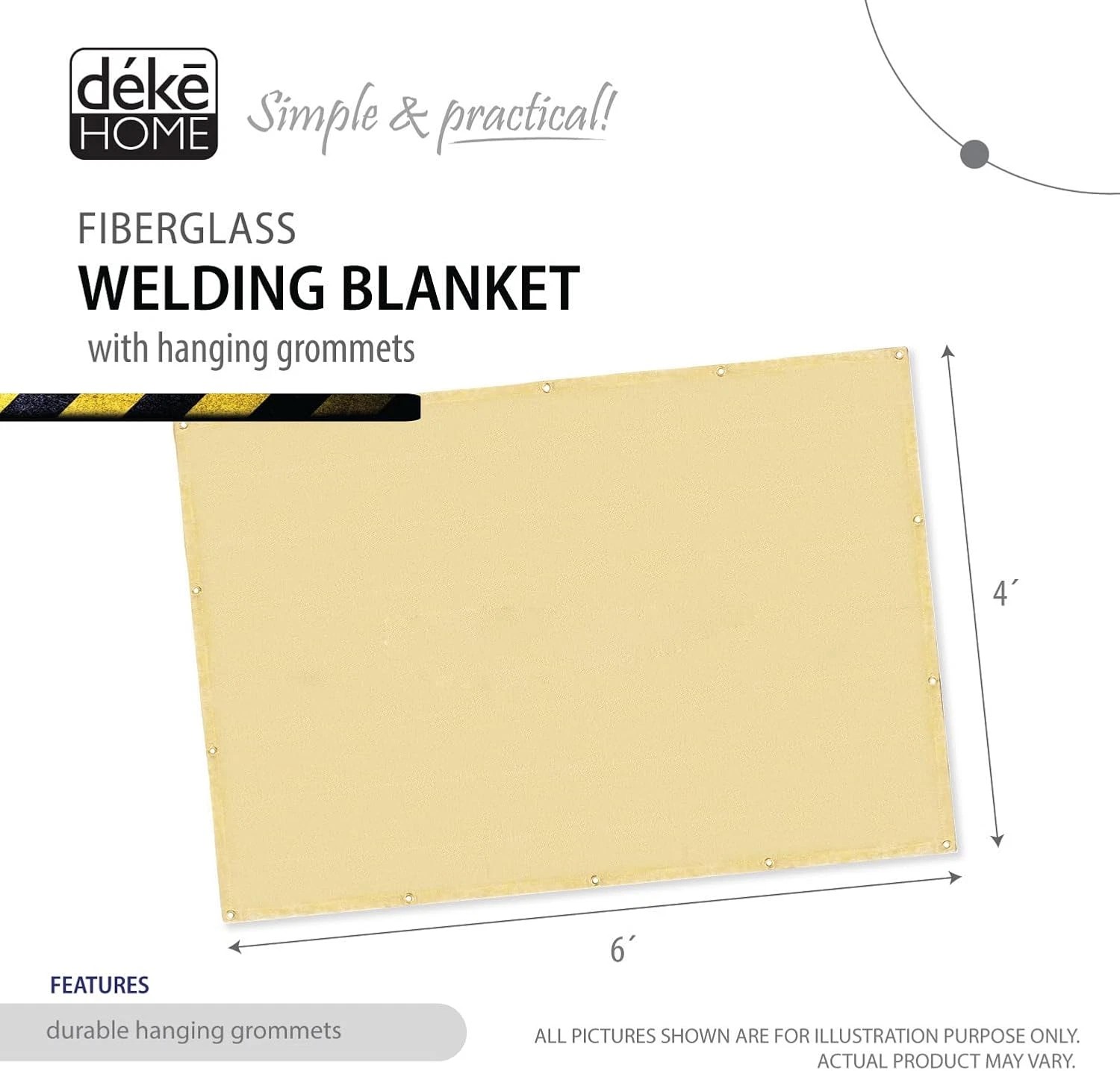

Fire blankets are specially designed materials that offer superior thermal insulation properties. Typically made from fiberglass or other fire-resistant materials, these blankets create a barrier that prevents heat transfer. When used for insulation, fire blankets can withstand temperatures up to 1000°F (538°C) or higher, depending on the specific material composition.

The insulation effectiveness comes from the blanket's ability to trap air between its fibers. This trapped air acts as an insulator, slowing down heat transfer through conduction and convection. The tightly woven fibers also minimize radiant heat transfer, making fire blankets for insulation particularly useful in high-temperature environments.

Key Benefits of Using Fire Blankets for Insulation

Choosing fire blankets for insulation offers several advantages:

- High-temperature resistance:Unlike conventional insulation materials, fire blankets maintain their structural integrity even under extreme heat.

- Flexibility:They can be easily cut and shaped to fit around pipes, equipment, or other irregular surfaces.

- Lightweight:Fire blankets add minimal weight compared to traditional insulation materials.

- Reusability:Many fire blankets can be reused after exposure to heat, unlike single-use thermal barriers.

- Dual-purpose:They serve both as insulation and emergency fire protection.

Common Applications of Fire Blankets for Insulation

Fire blankets find numerous insulation applications across various industries:

Industrial Equipment Insulation

In manufacturing plants, fire blankets insulate pipes, boilers, and heat exchangers. They help maintain process temperatures while protecting workers from burns. The blankets' flexibility allows easy installation around complex equipment shapes.

Welding Protection

Welders use fire blankets to insulate nearby materials from sparks and heat. The blankets prevent accidental fires while containing heat within the work area, improving welding efficiency.

HVAC Systems

Fire blankets provide thermal insulation for ductwork in heating, ventilation, and air conditioning systems. They help maintain air temperature while meeting fire safety requirements.

Automotive and Aerospace

In vehicles and aircraft, fire blankets insulate heat-sensitive components from engine heat. Their lightweight nature makes them ideal for applications where weight reduction is crucial.

Choosing the Right Fire Blanket for Insulation

When selecting a fire blanket for insulation purposes, consider these factors:

Temperature Rating

Match the blanket's maximum temperature rating to your application needs. Industrial applications typically require higher ratings (1000°F+) than household uses (500-800°F).

Material Composition

Fiberglass is common, but ceramic fiber blankets offer higher temperature resistance. Silica-based blankets provide excellent insulation with low thermal conductivity.

Thickness

Thicker blankets generally provide better insulation but may be less flexible. Balance insulation needs with installation requirements.

Size and Shape

Consider the surface area you need to cover. Some blankets come in rolls for custom cutting, while others are pre-cut to standard sizes.

Proper Installation and Maintenance

To maximize the insulation effectiveness of your fire blanket:

- Clean the surface before installation to ensure proper adhesion

- Use appropriate fasteners (wire, high-temperature tape, or clamps)

- Overlap seams by at least 2 inches for continuous coverage

- Inspect regularly for tears, compression, or contamination

- Replace if the blanket shows signs of degradation or has been exposed to extreme heat

Safety Considerations

While fire blankets are safe for insulation, follow these precautions:

- Wear gloves during handling to prevent skin irritation from fibers

- Use in well-ventilated areas when first installed (some materials may off-gas)

- Avoid compressing the blanket, as this reduces its insulating properties

- Keep away from open flames unless being used specifically for fire protection

Comparing Fire Blankets to Traditional Insulation

Fire blankets offer distinct advantages over conventional insulation materials:

| Feature | Fire Blankets | Traditional Insulation |

|---|---|---|

| Temperature Resistance | Extremely high (500-2000°F) | Moderate (typically below 400°F) |

| Fire Resistance | Excellent | Varies (often poor) |

| Flexibility | High | Low to moderate |

| Weight | Light | Often heavy |

| Durability | High | Moderate |

Conclusion

Fire blankets for insulation provide a versatile, high-performance solution for thermal protection in demanding environments. Their unique combination of heat resistance, flexibility, and safety features makes them superior to many traditional insulation materials for high-temperature applications. By selecting the appropriate blanket and installing it correctly, you can achieve excellent insulation while maintaining fire safety standards.

Whether for industrial equipment, welding protection, or specialized applications, fire blankets offer reliable insulation that stands up to extreme conditions. Their dual-purpose nature as both insulator and fire protector adds value to any thermal management system.