Valve Fire Protection Blanket: Essential Safety Solution for Industrial Pipes

Summary:Valve fire protection blankets are specialized safety covers that prevent flammable valve leaks from igniting. This guide explains their materials, installation, applications, and how they outperform traditional methods in industrial fire prevention.

What Is a Valve Fire Protection Blanket?

When you need to protect valves from fire hazards, a valve fire protection blanket provides targeted defense. These flexible covers wrap around pipes and valves to contain leaks and block ignition sources. Unlike rigid fireproof casings, blankets adapt to irregular shapes while maintaining thermal insulation up to 2000°F (1093°C).

Key Features That Matter

Your valve fire protection blanket should include:

- Fiberglass/silica fabric:Withstands direct flame contact

- Vermiculite coating:Expands under heat to seal gaps

- Stainless steel fasteners:Ensures secure fit during emergencies

- Chemical resistance:Protects against oil, solvents, and acids

Where You Need These Blankets

Install valve fire protection blankets in high-risk areas:

- Oil/gas pipelines:Prevents wellhead valve fires

- Chemical plants:Contains corrosive fluid leaks

- Power stations:Shields steam valve assemblies

- Marine engine rooms:Complies with SOLAS regulations

Installation Best Practices

Follow these steps to maximize your valve fire protection blanket's effectiveness:

1. Clean the surface:Remove oil/grease from valves first2. Overlap coverage:Ensure 2-inch minimum overlap at seams3. Secure properly:Use all provided straps without over-tightening

Why They Outperform Traditional Methods

Compared to spray-on coatings or concrete enclosures, valve fire protection blankets offer:

| Feature | Blankets | Traditional Methods |

|---|---|---|

| Installation Time | 5-15 minutes | 2-8 hours |

| Maintenance | Visual inspection | Ultrasonic testing |

| Reusability | Yes (after inspection) | No |

Certifications to Look For

Ensure your valve fire protection blanket meets:

- UL 1709 (rapid temperature rise test)

- ASTM E84 (surface burning characteristics)

- IMO FTP Code (marine applications)

- EN 13501-1 (European fire classification)

Common Mistakes to Avoid

Don't compromise safety by:

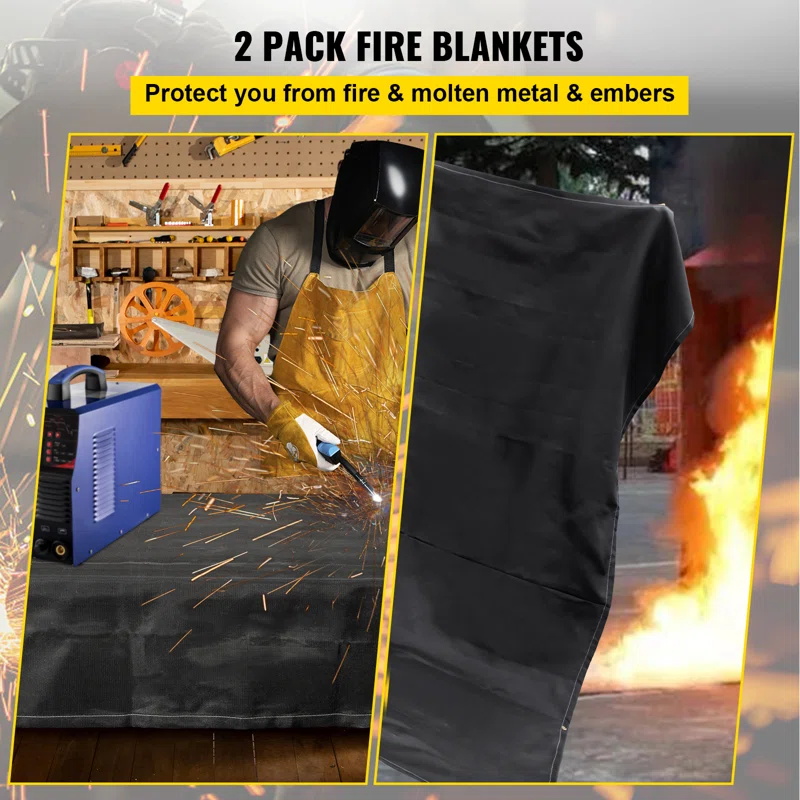

- Using general-purpose welding blankets instead of specialized valve fire protection blankets- Installing damaged blankets (even small tears reduce effectiveness)- Blocking emergency shut-off access when positioning blankets

Maintenance Checklist

Keep your valve fire protection system reliable with:

✓ Monthly visual inspections✓ Annual professional testing✓ Immediate replacement after fire incidents✓ Proper storage for spare blankets (cool, dry place)

When to Upgrade Your Protection

Consider new valve fire protection blankets if:

- Your current blankets show stiffness or discoloration- Process temperatures have increased- New regulations require higher safety standards- Blankets have reached 5-year service life (manufacturer recommendation)