Ultimate Guide to Tillman's Welding Blankets: Protection & Safety Tips

Tillman's welding blankets provide essential protection against sparks, slag, and heat during welding projects. This guide explains their materials, uses, safety benefits, and how to choose the right one for your needs.

Why Tillman's Welding Blankets Are Essential

When you're welding, safety should always come first. Tillman's welding blankets protect your workspace from sparks that could cause fires. These durable covers shield nearby equipment, vehicles, or flammable materials from welding heat and molten metal splatter.

Unlike regular tarps, Tillman's blankets are specifically designed for high-temperature applications. They won't melt or catch fire when exposed to welding sparks. The fiberglass construction provides excellent heat resistance while remaining flexible enough to drape over irregular shapes.

Key Features of Tillman's Welding Blankets

Understanding these features helps you select the best blanket for your projects:

- Heat resistance:Withstands temperatures up to 1,000°F (538°C) continuously

- Material:Woven fiberglass with silicone coating for durability

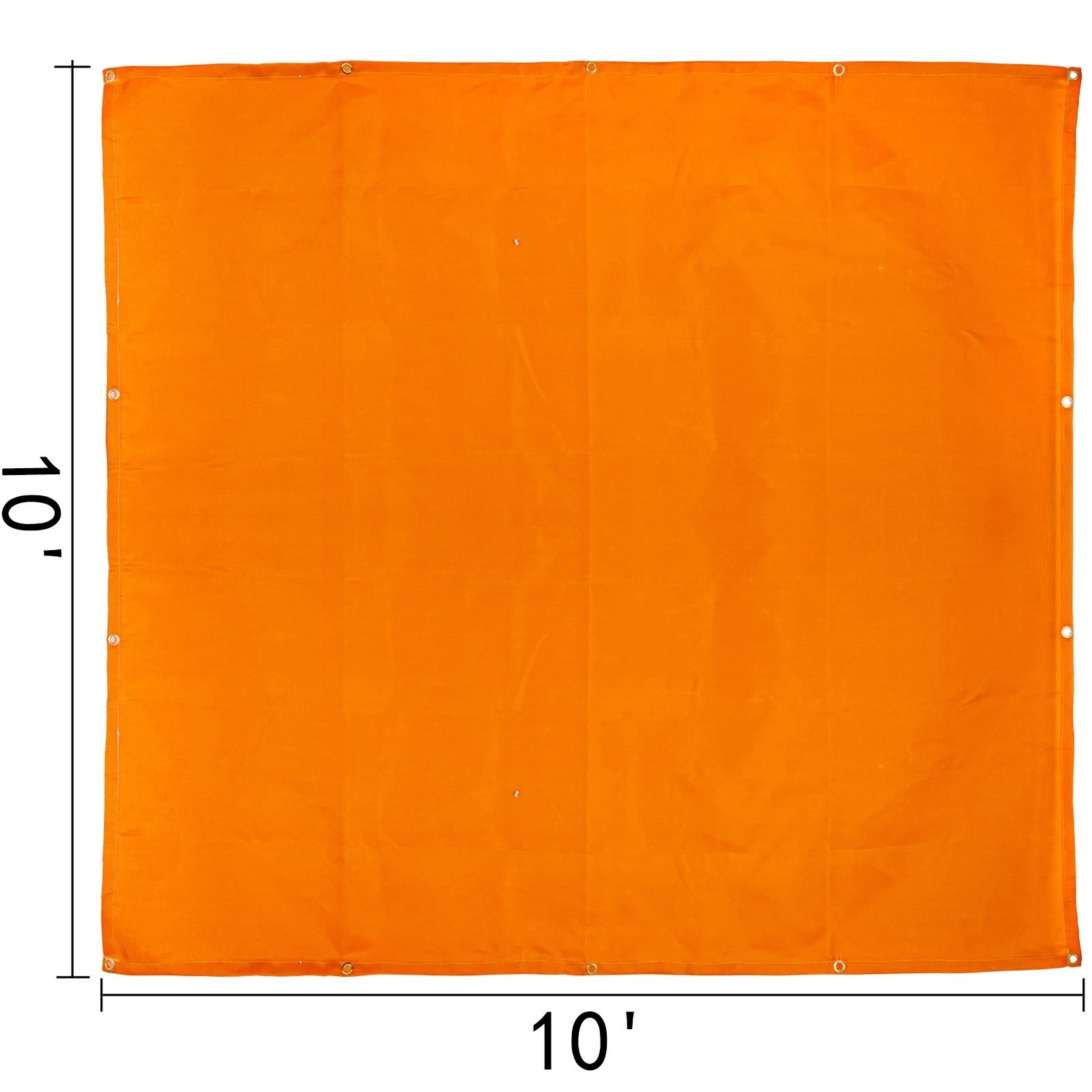

- Sizes:Available in various dimensions from 3'x3' to 12'x12'

- Weight:Heavy-duty construction that doesn't tear easily

- Color options:Typically silver-gray for heat reflection

How to Use Your Tillman Welding Blanket Safely

Proper use ensures maximum protection:

- Inspect the blanket before each use for any tears or damage

- Cover all nearby flammable materials completely

- Secure the blanket with weights or clamps to prevent movement

- Keep the blanket at least 3 feet away from the actual welding point

- Allow the blanket to cool completely before folding or storing

Remember that while Tillman's welding blankets provide excellent protection, they should complement other safety measures like proper ventilation, protective clothing, and fire extinguishers.

Choosing the Right Tillman Blanket for Your Needs

Consider these factors when selecting your welding blanket:

Project size:Larger projects need bigger blankets. For automotive work, a 6'x6' blanket often works well, while industrial applications may require 12'x12' coverage.

Welding type:Higher-amperage welding like stick or flux-core produces more sparks than MIG or TIG, potentially requiring heavier-duty protection.

Work environment:Confined spaces benefit from smaller, more maneuverable blankets, while open areas can use larger ones.

Maintenance and Care Tips

Extend your Tillman welding blanket's lifespan with proper care:

- Shake off slag and debris after each use

- Store in a dry place away from direct sunlight when not in use

- Fold carefully to prevent creasing that could weaken fibers

- Clean with compressed air or a soft brush - never use water or chemicals

- Replace the blanket if you notice significant wear or holes

Beyond Welding: Other Uses for Tillman Blankets

These versatile blankets have applications beyond welding:

Grinding protection:Shield surfaces from sparks during metal grinding operations.

Fireproofing:Use as temporary protection for walls or floors during hot work.

Heat containment:Contain heat from torches or heat guns during plumbing or automotive work.

Investing in a quality Tillman welding blanket protects your workspace, prevents costly damage, and most importantly - keeps you safe. Choose the right size and thickness for your specific needs, use it properly, and maintain it well for years of reliable service.