Silicone Coated Welding Blanket: Heat Protection for Safe Welding

A silicone coated welding blanket protects surfaces from sparks and heat during welding. This guide explains its features, benefits, and how to choose the right one for your needs.

What Is a Silicone Coated Welding Blanket?

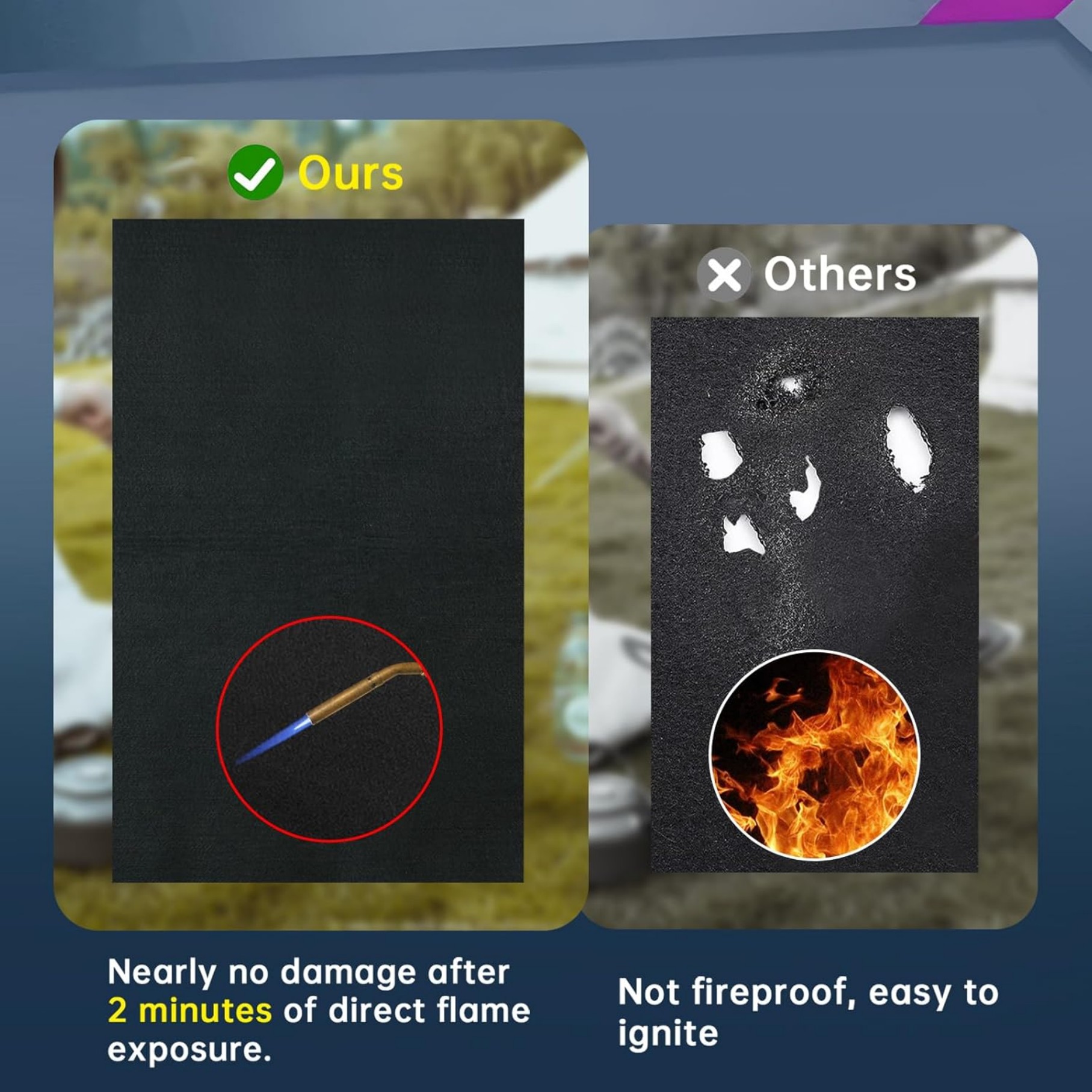

A silicone coated welding blanket is a heat-resistant fabric made from fiberglass with a silicone rubber coating. Unlike regular welding blankets, the silicone coating provides extra durability and resistance to extreme temperatures up to 1000°F (540°C). The coating also makes the blanket more flexible and tear-resistant.

Key Benefits You Should Know

- Superior heat protection:Withstands direct flame contact and molten metal splatter

- Reusable:Doesn't degrade quickly like untreated fiberglass blankets

- Easy to clean:Wipe off slag and debris without damaging the material

- Non-conductive:Safe for electrical work environments

- Flexible:Conforms to uneven surfaces better than rigid shields

Where to Use Silicone Coated Welding Blankets

These blankets aren't just for welding. You'll find them useful for:

- Protecting floors and walls in auto body shops

- Covering sensitive equipment near hot work areas

- Creating temporary fire barriers on construction sites

- Shielding wooden surfaces during metal cutting

- Industrial furnace maintenance and repair

Choosing the Right Blanket

Consider these factors when selecting your silicone coated welding blanket:

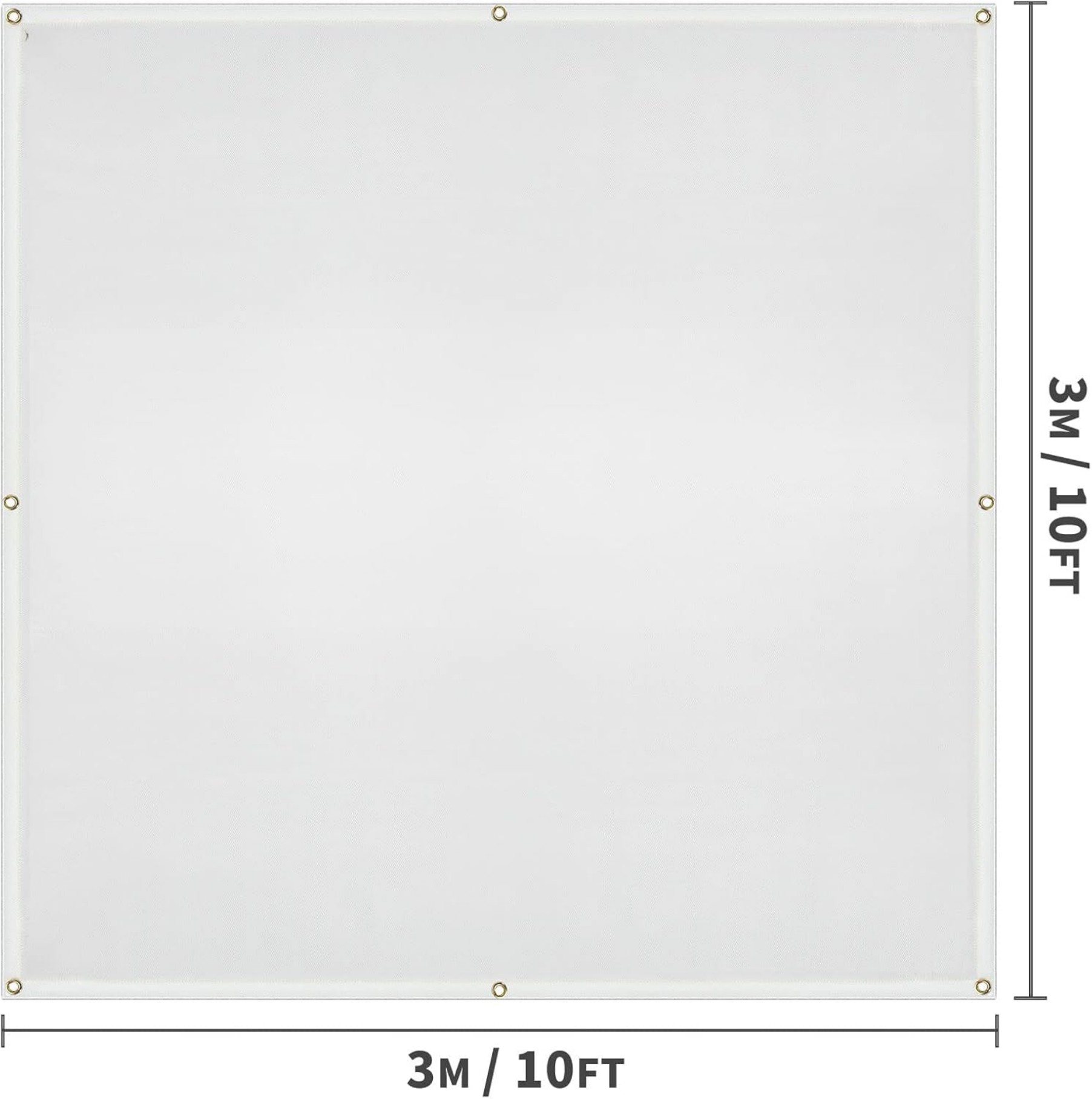

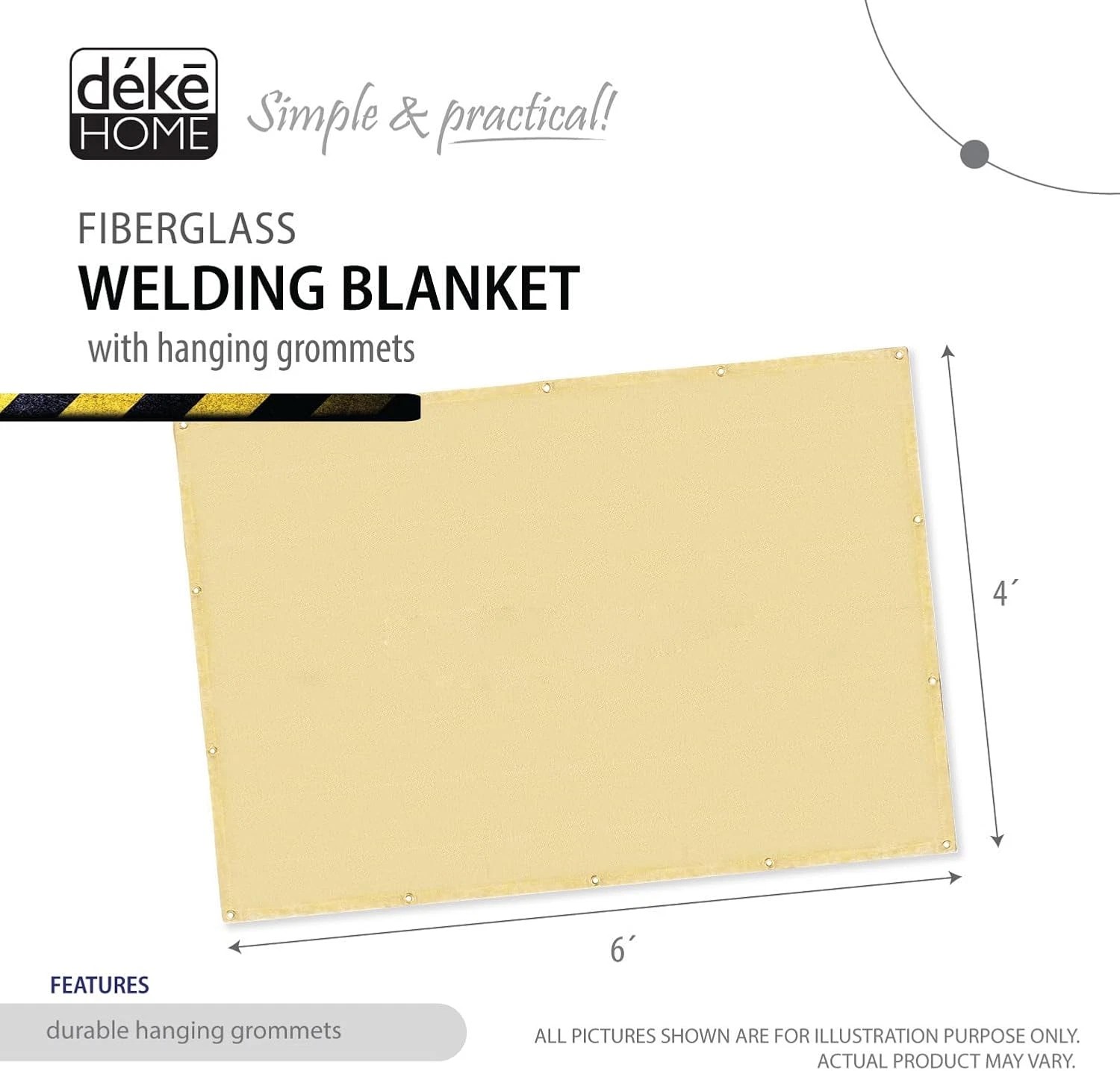

- Size:Measure your work area - common sizes range from 3'x3' to 10'x10'

- Thickness:Thicker blankets (1/16" to 1/8") offer better protection for heavy-duty work

- Color:Silver-gray is standard, but some manufacturers offer high-visibility colors

- Edge treatment:Look for reinforced edges with grommets for hanging

- Certifications:Check for NFPA 701 or other relevant safety standards

Proper Care and Maintenance

To extend your blanket's lifespan:

- Shake off loose debris after each use

- Wipe with a damp cloth for stubborn residues

- Store flat or rolled - avoid folding to prevent creases

- Inspect regularly for tears or thinning areas

- Replace when the silicone coating shows significant wear

Safety Tips When Using Welding Blankets

While silicone coated blankets offer excellent protection, remember:

- Never use as personal protective equipment - wear proper welding gear

- Keep at least 12 inches away from open flames

- Don't use on surfaces hotter than the blanket's rated temperature

- Ensure proper ventilation when covering large areas

- Have a fire extinguisher nearby as an extra precaution

Comparing Silicone vs. Non-Coated Welding Blankets

Silicone coated versions outperform standard fiberglass blankets in several ways:

- Last 3-5 times longer with proper care

- Resist moisture and chemical exposure better

- Maintain flexibility in cold temperatures

- Don't shed irritating fibers

- Provide smoother surface for easier cleanup

Final Thoughts

A quality silicone coated welding blanket is a smart investment for anyone doing frequent welding or hot work. While more expensive initially than uncoated options, the extended lifespan and superior protection make it cost-effective over time. Choose the right size and thickness for your applications, maintain it properly, and you'll have reliable heat protection for years.