Welding Heat Retention Blanket: Uses, Benefits & How It Works

A welding heat retention blanket slows cooling in welded joints, preventing cracks and improving strength. This guide explains how it works, its benefits, and best practices for use.

What Is a Welding Heat Retention Blanket?

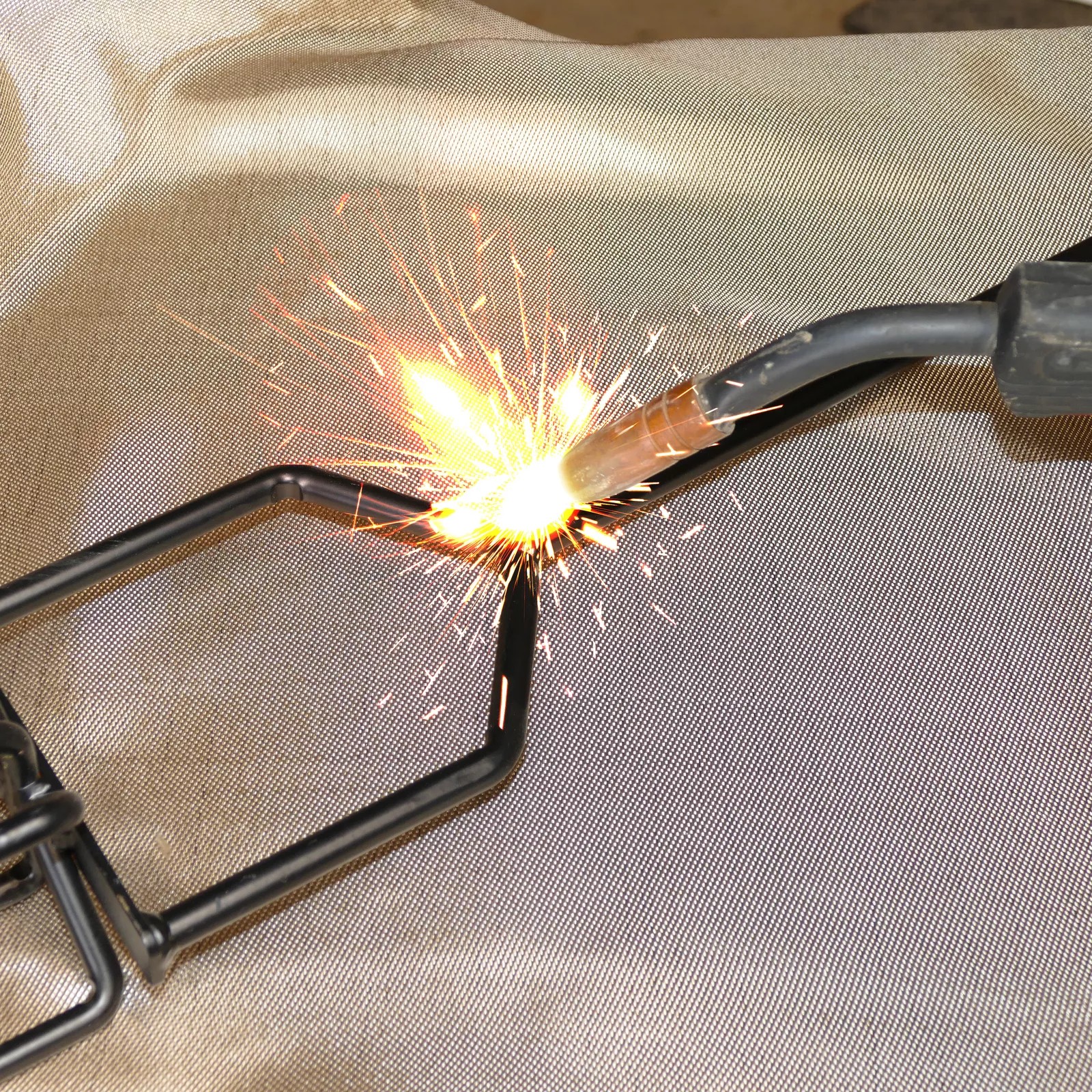

A welding heat retention blanket is a specialized insulating wrap that maintains consistent temperatures around welded joints. It's made from heat-resistant materials like ceramic fiber or silica fabric, designed to trap heat and control cooling rates. You use it after welding to protect the joint from rapid temperature drops that can weaken the metal.

Why Use a Welding Heat Retention Blanket?

When you weld, sudden cooling creates stress and cracks. A heat retention blanket solves this by:

- Preventing cracks:Slower cooling reduces thermal stress in metals like steel and aluminum.

- Saving energy:Less reheating is needed for multi-pass welds.

- Improving weld quality:Maintains ductility and toughness in the joint.

How to Use a Welding Heat Retention Blanket

Follow these steps for best results:

- Wrap the blanket around the welded area immediately after finishing.

- Secure it with straps or wires to ensure full contact.

- Leave it until the temperature drops below critical levels (check material specs).

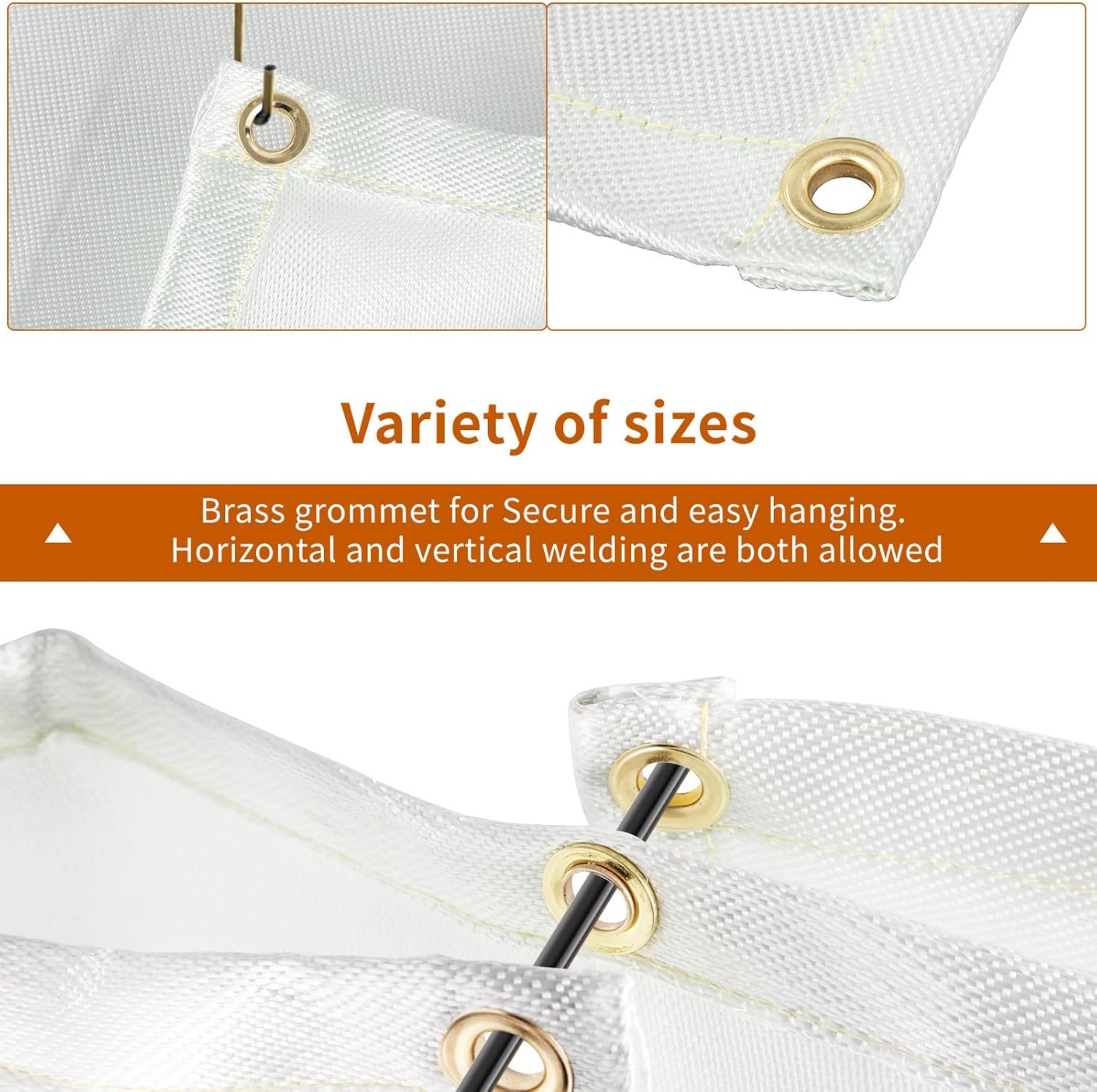

Choosing the Right Blanket

Key factors when selecting a welding heat retention blanket:

| Feature | Why It Matters |

|---|---|

| Temperature rating | Must withstand your welding process (e.g., 2000°F for arc welding) |

| Material | Ceramic fibers for high heat, fiberglass for lower temps |

| Thickness | Thicker blankets retain heat longer |

Common Applications

Welding heat retention blankets are used in:

- Pipeline welding

- Shipbuilding

- Pressure vessel construction

- Structural steel projects

Safety Tips

Remember these precautions:

- Inspect blankets for damage before each use

- Wear gloves when handling hot blankets

- Store in dry conditions to prevent moisture absorption

Maintenance and Care

To extend your welding heat retention blanket's life:

- Clean with compressed air (never water)

- Fold carefully to avoid fiber breakage

- Replace if you see significant wear or tears

FAQs

Q: Can I reuse a welding heat retention blanket?A: Yes, most are reusable unless physically damaged.

Q: How long should I leave the blanket on?A: Typically until the temperature drops below 300°F, but check your welding procedure.

Q: Are these blankets flammable?A: No, quality welding blankets are non-combustible.